Method for separating n-alkanes in gasoline to improve octane number of gasoline

A gasoline octane number and gasoline technology, which is applied in the field of separating n-alkanes in gasoline to increase gasoline octane number, can solve the problems of inability to separate n-alkanes, low distillation range and low octane number of catalytic cracking gasoline, and achieve environmental friendliness , Simple equipment, stable separation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

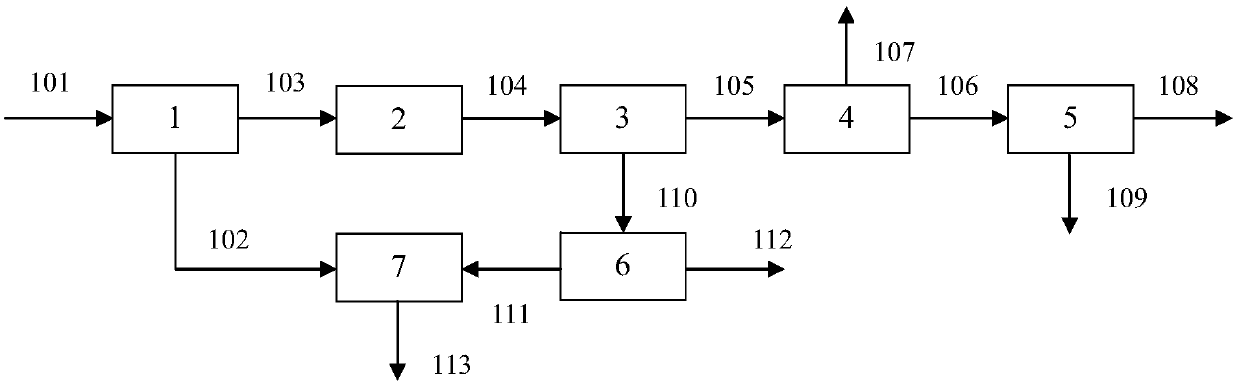

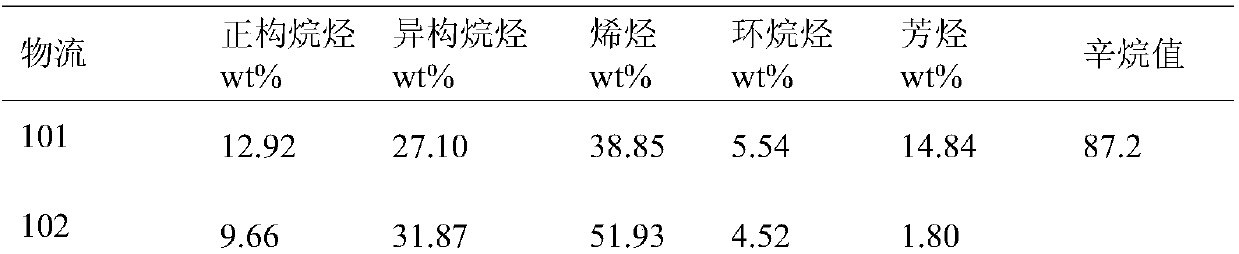

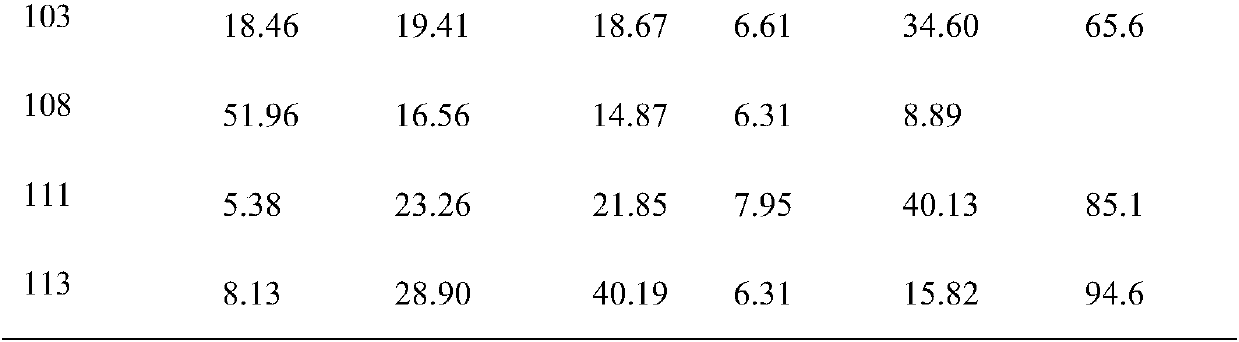

[0042] according to figure 1 The process shown is to purify and recover FCC gasoline, and cut 100kg / h FCC gasoline 101 into 50kg light component oil 102 and 50kg heavy component oil 103 through step 1 at 100°C; heavy component oil 103 is added to 50kg through step 2 / h urea and thiourea (urea: thiourea=1:1, mass ratio) in absolute ethanol solution, gradually cool down to -10°C and stir to obtain a suspension 104; the suspension 104 is vacuum filtered 3 to obtain a solid phase Product 105 and liquid phase product 110; solid phase product 105 is dissolved by adding water in step 4 to obtain oil phase product 106 and cleaning water 107, the quality of the added water is 100~150kg / h; cleaning water 107 can be separated to obtain complexing agent and water; Oil phase product 106 is further washed with water through step 5, and the quality of water is 100~150kg / h, obtains oil phase product 108 (i.e. removed n-paraffin) and cleaning water 109; The liquid phase product 110 that obtain...

Embodiment 2

[0048] according to figure 1 The process shown is to purify and recycle FCC gasoline, cut 100kg / h FCC gasoline 101 into light component oil 102 and heavy component oil 103 through step 1 at 70°C; heavy component oil 103 is added to urea and sulfur through step 2 In the ethanol saturated solution of urea (urea: thiourea=1:1, mass ratio), the mass ratio of the total mass of urea and thiourea to the heavy component oil 103 is 1:1, gradually cool down to -10°C and stir to obtain a suspension Turbid liquid 104; Suspension liquid 104 obtains solid-phase product 105 and liquid-phase product 110 through vacuum filtration 3; Solid-phase product 105 obtains oil-phase product 106 and cleaning water 107 through step 4 and dissolves, and the quality of added water is 100~150kg / h; Cleaning water 107 can be separated to obtain complexing agent and water; Oil phase product 106 is further washed with water through step 5, and the quality of water is 100~150kg / h, obtains oil phase product 108 ...

Embodiment 3

[0053] according to figure 1 The process shown is to purify and recycle FCC gasoline, cut 100kg / h FCC gasoline 101 into light component oil 102 and heavy component oil 103 through step 1 at 100°C; In the ethanol saturated solution of biurea (urea: biuret = 1:1, mass ratio), the mass ratio of the total mass of urea and biuret to the heavy component oil 103 is 1:1, gradually cool down to 0°C and stir Obtain suspension 104; Suspension 104 obtains solid phase product 105 and liquid phase product 110 through vacuum filtration 3; Solid phase product 105 obtains oil phase product 106 and cleaning water 107 through step 4 water dissolving, and the quality of added water is 100 ~150kg / h; Washing water 107 can be separated to obtain urea and water; Oil phase product 106 is further washed with water through step 5, and the quality of water is 100~150kg / h, obtains oil phase product 108 (the n-paraffin that is removed) and Washing water 109; the liquid phase product 110 obtained after vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com