Method of Realizing Fabric Dyeing by Utilizing Polymer Materials

A polymer material and fabric dyeing technology, applied in the field of fabric dyeing, can solve the problems of polluted water, land salt, high salt content in sewage, alkalization, etc., and achieve the effects of clean and environmentally friendly production, reasonable dyeing process, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Taking the thin cotton fabric as an example, the printing and dyeing method of the present invention is specifically as follows:

[0042] Configure dye working solution→configure special color fixing agent working solution→proportion pump 4:1→configure into dyeing working solution→pad dyeing working solution (rolling rate 55-65%)→drying (80°C, keep the cloth surface containing Moisture rate 6.5%-8.5%)→Steam fixation (102℃x60-80 seconds)→Two compartments of cold water washing (20-30℃)→Two compartments of warm water washing (40-50℃)→Three compartments of soaping (soaping Lotion 4g / L, temperature 95-98°C) → two compartments of warm water (70-80°C) → one compartment of cold water (30-40°C) → drying;

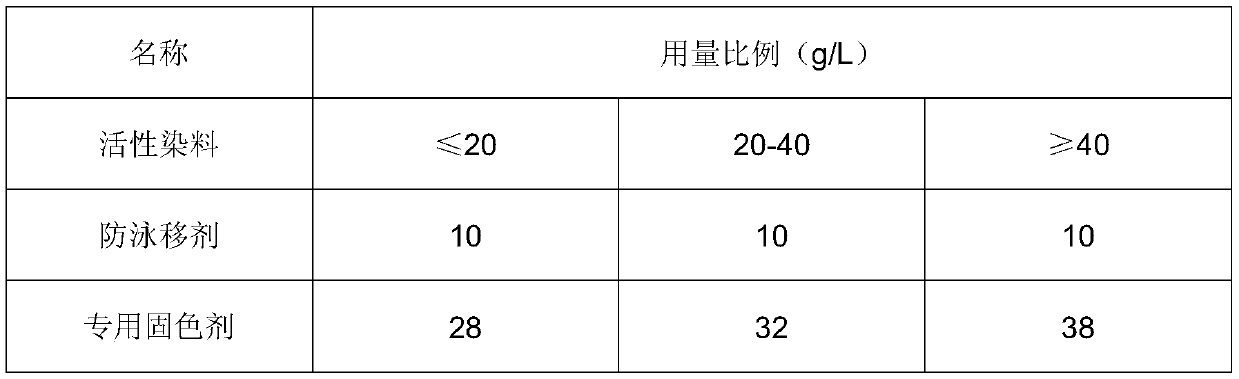

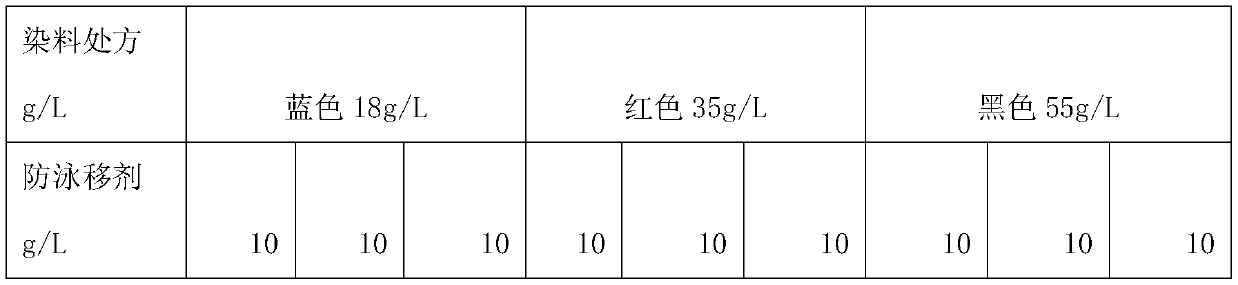

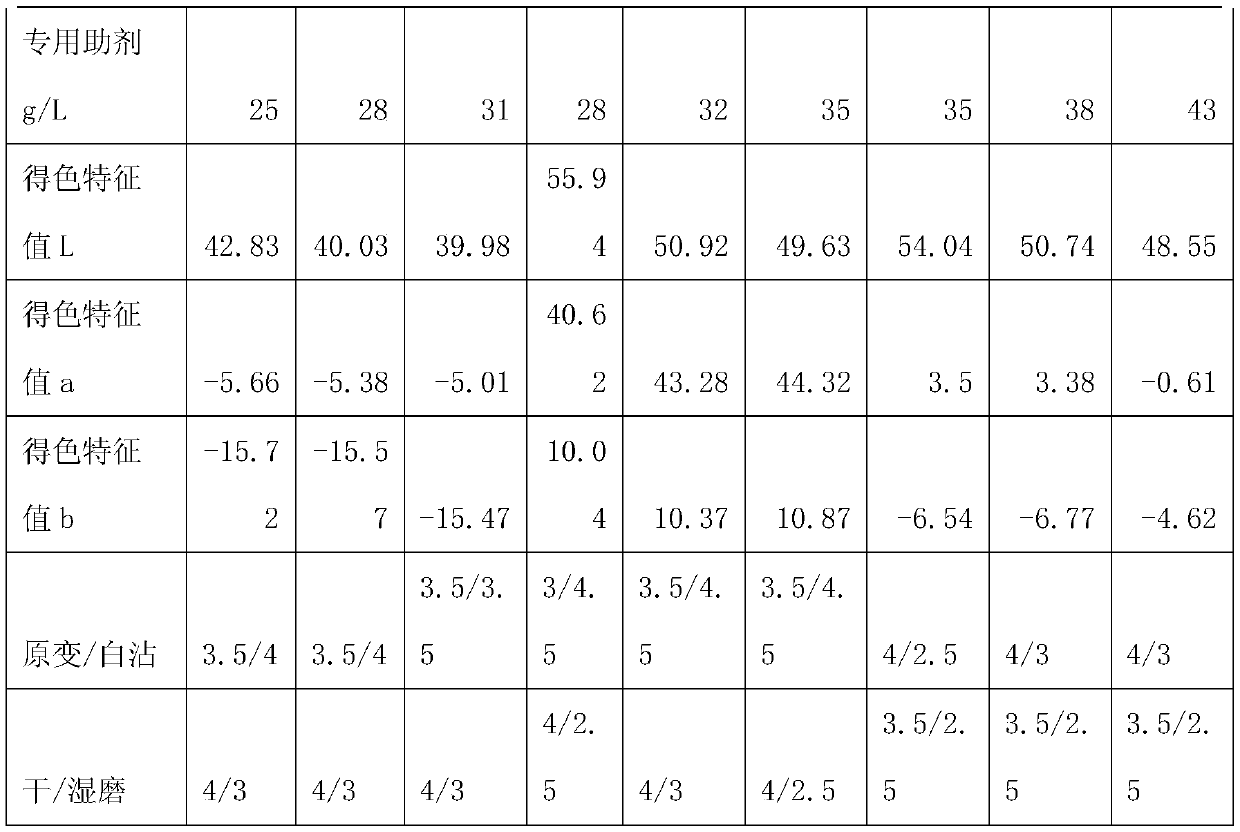

[0043] Process recipe

[0044]

[0045] The composition of the special color fixing agent: 750 parts of sodium metasilicate pentahydrate, 250 parts of urea, and 2 parts of sodium dodecylbenzenesulfonate, all in parts by weight; the reactive dye is a commonly used common dy...

Embodiment 2

[0071] Take thick and thick fabric as example, illustrate technique of the present invention, specifically as follows:

[0072] 1 chemical material: high level tank dye and special color fixing agent (735 parts of sodium metasilicate pentahydrate, 260 parts of urea, 2 parts by weight of sodium dodecylbenzenesulfonate) separate chemical material, reactive dye and anti-swimming agent cable Lideco V is converted into a chemical tank, and the special color fixing agent is separately converted into a chemical tank. The dosage of the special color fixing agent is: light color 28g / L, medium color 32g / L, dark color 38g / L. Through the proportional pump according to the ratio of dye: special color fixing agent of 4:1 (volume) is added to the rolling tank through the one-way valve, and the working error of the proportional pump is not more than 2% within 10 hours;

[0073] 2 Rolling material: The semi-finished fabric is dipped and rolled in the rolling material tank, and then passed thro...

Embodiment 3

[0079] In the color fixing agent, 740 parts of sodium metasilicate pentahydrate, 260 parts of urea, 2 parts of sodium dodecylbenzenesulfonate, and the rest are the same

[0080] Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com