Fiber bragg grating vibration measurement system based on pulse coding and edge filtering method

A technology of fiber grating and pulse coding, which is applied in the direction of measuring device, measuring ultrasonic/sonic wave/infrasonic wave, using wave/particle radiation, etc. It can solve the problem of attenuation of feedback signal of fiber grating vibration sensor, insufficient accuracy of measurement results, and limitation of measurement distance and other issues, to achieve the effect of improving spatial resolution, increasing measurement distance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

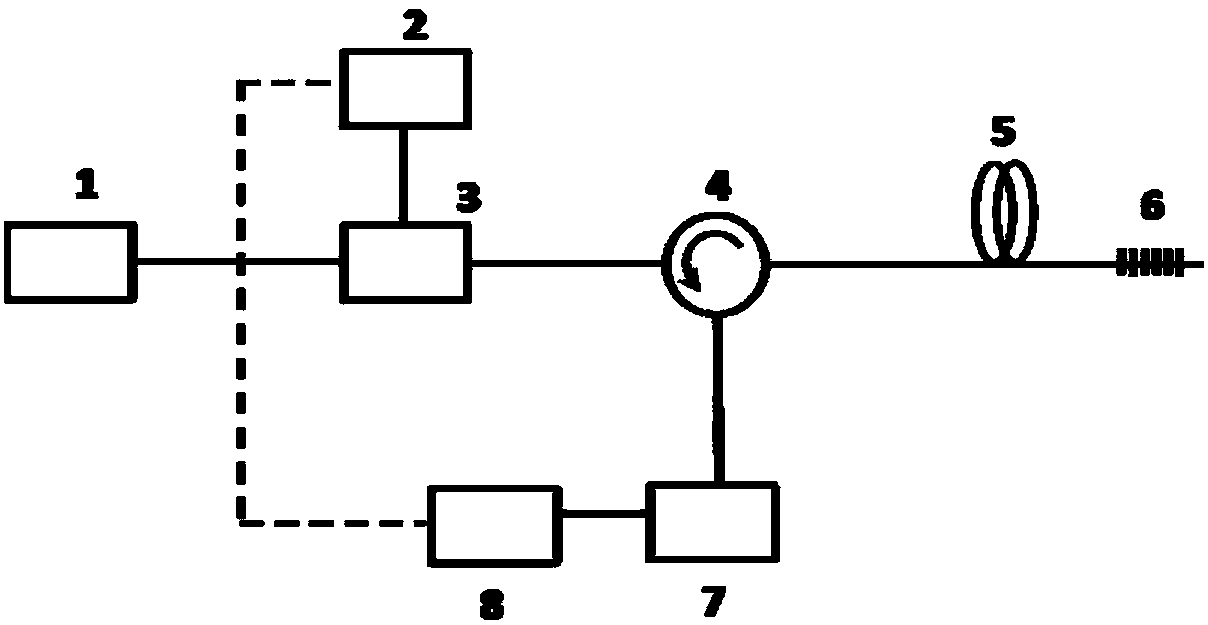

[0029] see figure 1 , in a preferred embodiment of the present invention, the fiber grating vibration measurement system based on pulse coding and edge filtering method includes a narrow linewidth laser 1, a pulse signal generator 2, an electro-optic modulator 3, a circulator 4, a single mode fiber 5, fiber grating 6, photodetector 7 and digital signal processing unit 8. The output end of the narrow linewidth laser 1 is connected to the optical input end of the electro-optic modulator 3, and the continuous light output by it is injected into the electro-optic modulator 3 through the optical input end of the electro-optic modulator 3; the pulse signal generator 2 The output terminal of the electro-optic modulator is connected to the radio frequency input terminal of the electro-optic modulator 3, and the coded electrical pulse signal output by it is injected into the electro-optical modulator 3 through the radio frequency input terminal of the electro-optic modulator 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com