A test device and method for simulating the corrosion of steel materials in the environment of deicing agent

A technology for corrosion testing and steel materials, applied in measuring devices, analysis materials, weather resistance/light resistance/corrosion resistance, etc., can solve problems that are simple and cannot be simulated by multiple factors, and achieve reliability assurance, low manufacturing and operating costs, and The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

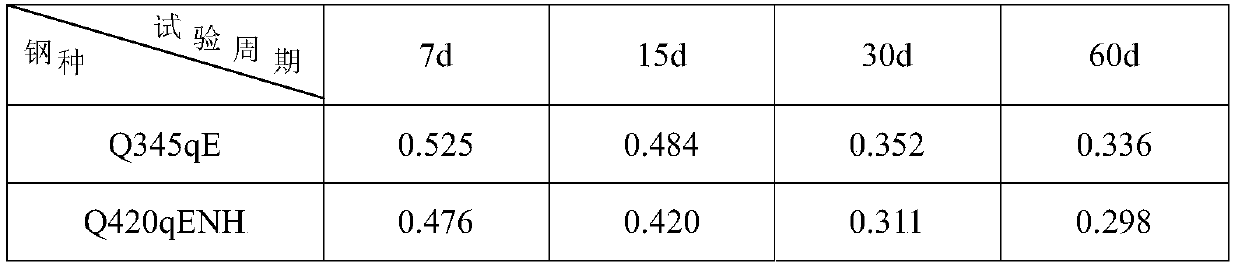

[0025] Example 1: The corrosion behavior of common carbon bridge steel Q345qE and weather-resistant bridge steel Q420qENH in the environment of deicing agent was studied by using the patent of the present invention.

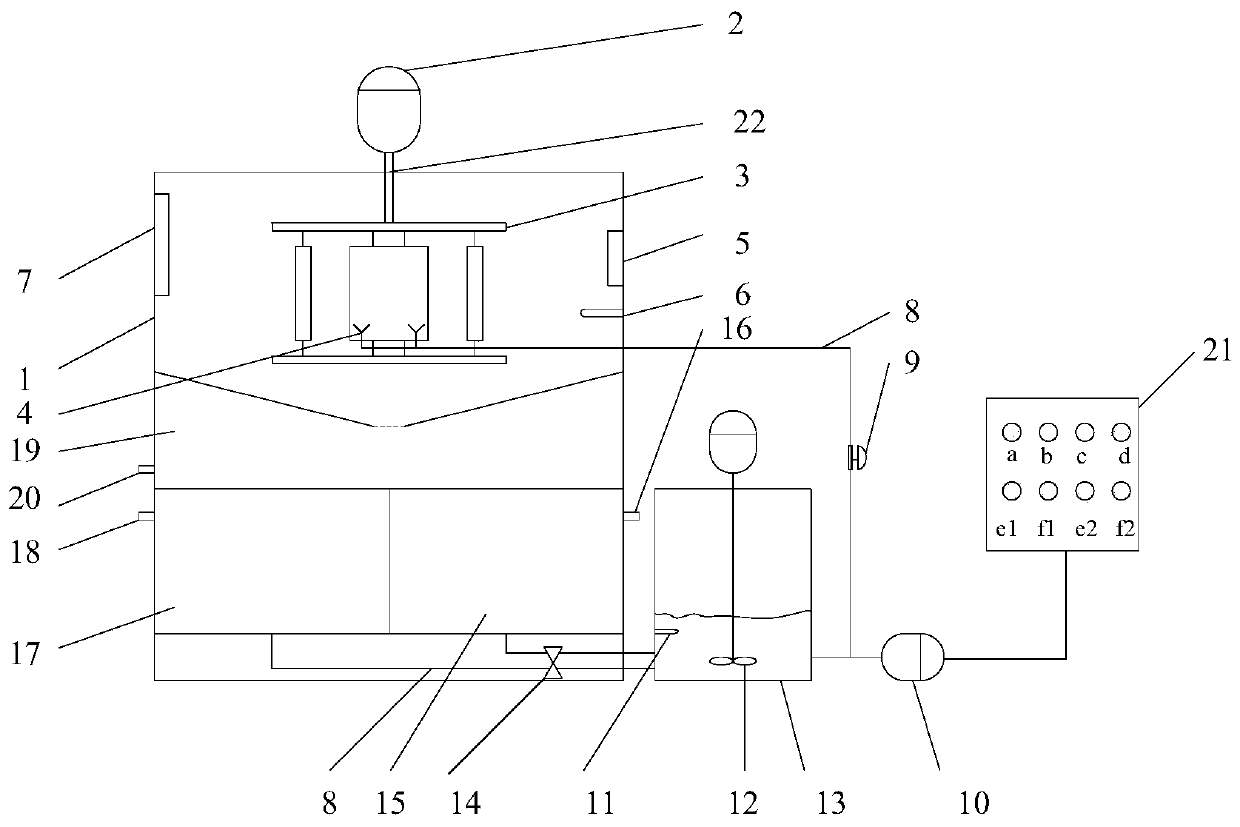

[0026] Take 3 parallel samples of each of the two steel types, and the processing size is 100×50×5mm. After milling and grinding machines, the smoothness is above grade 7. After hot alkali washing→deionized water washing→alcohol cleaning→drying, put After entering the desiccator for 12 hours, weigh and record. The sample is suspended on the sample holder 3 by an insulating thin wire, deionized water is injected into the deionized water tank 17, and a concentration of 30% chlorine salt deicing agent is injected into the deicing agent concentrated liquid tank 15, the main switch a is turned on, and the electronic control Knob b of the thermometer sets the temperature to -20°C, sets the total flow adjustment knob c to 0.5Mpa on the control system panel 21, adjusts t...

Embodiment 2

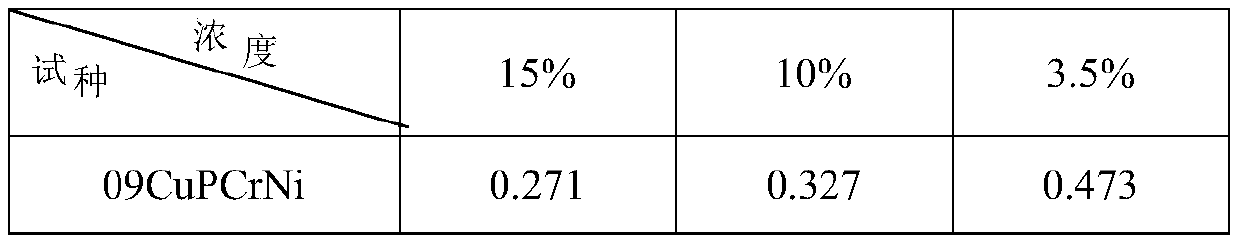

[0031] Example 2: Utilize the patent of the present invention to study the corrosion resistance behavior of weathering steel 09CuPCrNi under different concentrations (15%, 10%, 3.5%) of the same deicing agent, carry out three tests in total, and remove deicing agent during the three tests Mixed solution concentration knob IIe2 concentration setting is different, other parameters are the same, and the operation method is similar to embodiment 1: configure 20% chlorine salt deicing agent to inject deicing agent concentrated solution tank 15, and the electronic temperature controller knob b sets the temperature to - 10°C, on the control system panel 21, set the total flow adjustment knob c to 0.3Mpa, adjust the concentration knob d of the snowmelting agent concentrated solution to set the concentration to 20%, and adjust the concentration knob Ie1 of the snowmelting agent mixed solution to set the concentration to 0% At the same time, adjust the time relay f1 to 30min, adjust the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com