Silicon hollow beam, silicon micro-accelerometer based on silicon hollow beam and preparation method thereof

An accelerometer, hollow technology, used in the measurement of acceleration, velocity/acceleration/shock measurement, instruments, etc., can solve the problem of large bending modal interference of support beams, temperature characteristics and robustness limitations, poor anti-modal interference capabilities, etc. problem, to achieve the effect of improving anti-interference ability, low cost and high processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

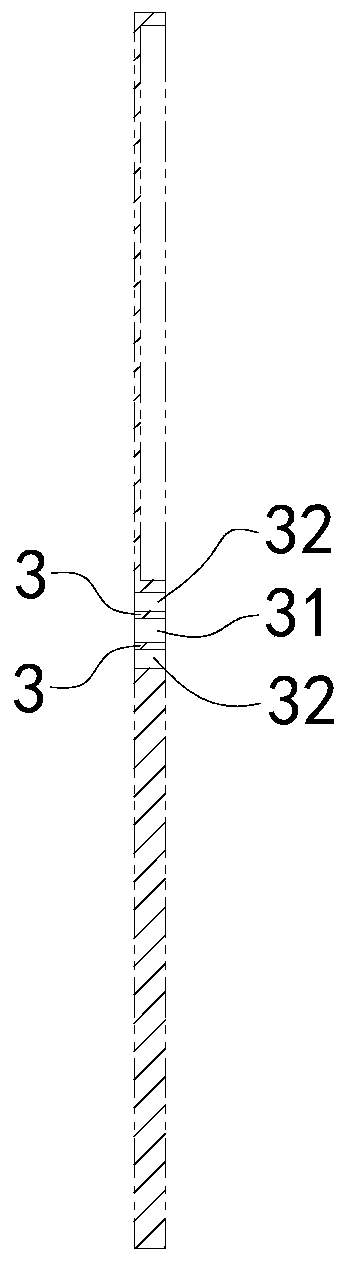

[0067] Such as Figure 8 and Figure 9As shown, the basic steps of the preparation method of the silicon micro-accelerometer based on the silicon hollow beam in this embodiment include: using dry etching to process the prepared silicon substrate, bonding the silicon substrate and a piece of SOI silicon wafer by low stress bonding, The micro-accelerometer is obtained by preparing a silicon-sensitive structure by dry etching, and its specific implementation steps include:

[0068] a) Prepare the first SOI wafer as a silicon substrate such as Figure 8 Shown in (a); In the present embodiment, the thickness of the device layer of the SOI silicon wafer is 6 microns;

[0069] b) The device layer of the silicon base is dry etched for the first time to form a gap between the silicon substrate 1 and the silicon sensitive structure 2; in this embodiment, the first dry etching of the silicon base is 2 microns, and the formed gap is as follows Figure 8 as shown in (b);

[0070] c) On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com