Organic EL film, organic EL display and organic EL illumination

An organic, display technology, applied in applications, home appliances, other home appliances, etc., that can solve problems such as curling, poor thermal dimensional stability, and insufficient rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

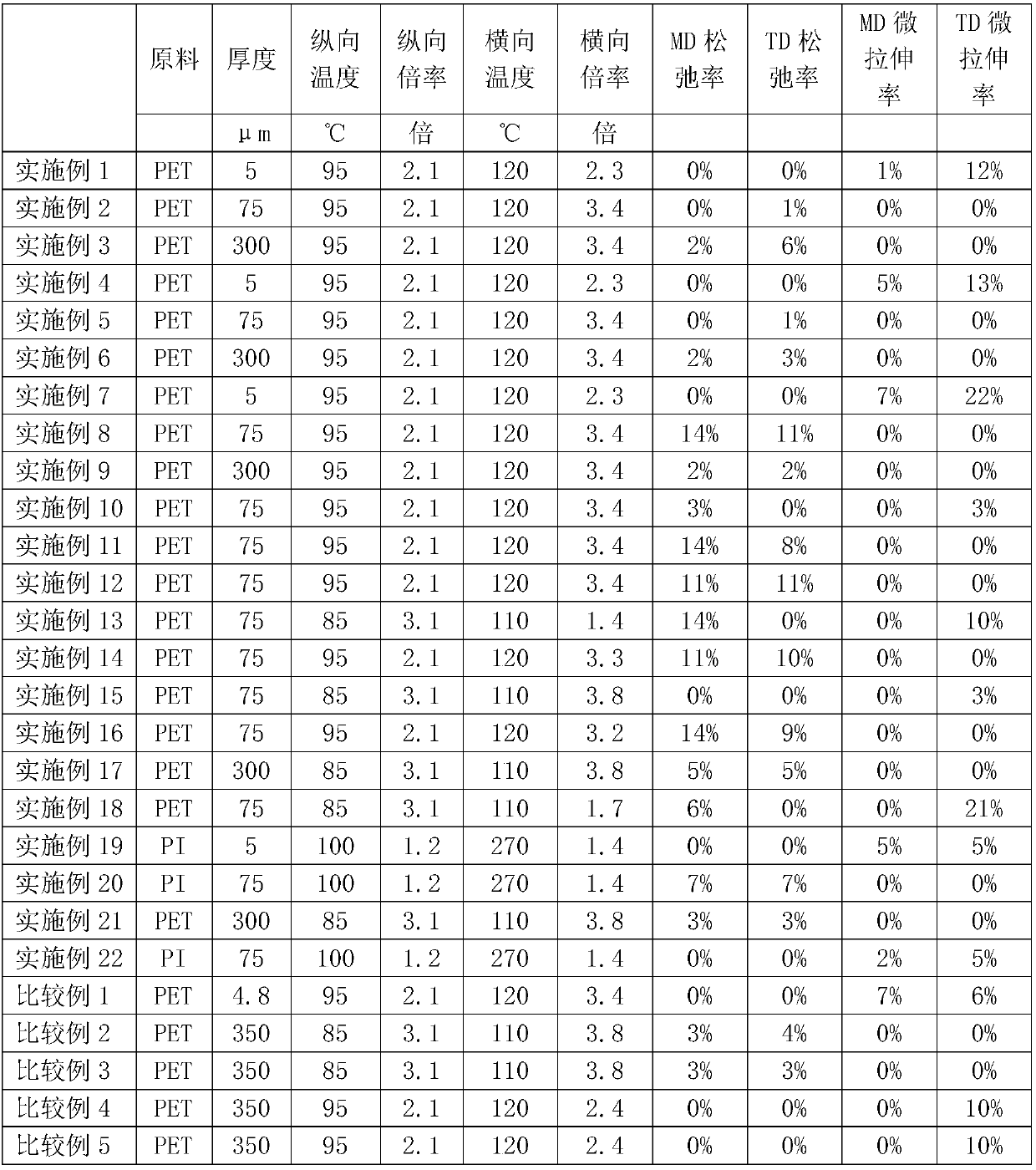

[0144] Using terephthalic acid as the acid component and ethylene glycol as the diol component, antimony trioxide (polymerization catalyst) was added to the obtained polyester pellets at 300 ppm in terms of antimony atoms, and polycondensation reaction was carried out to obtain A polyethylene terephthalate pellet having an intrinsic viscosity of 0.63 dl / g and a carboxyl terminal group weight of 40 equivalents / ton was obtained.

[0145] First, the polyester was vacuum-dried at 150°C for 2 hours, then vacuum-dried at 180°C for 2 hours, supplied to an extruder and melted at 285°C, filtered through a 3 μm cut-off filter, and then filtered by a T-shaped spray The nozzle is extruded in the form of a sheet, and is wrapped on a mirror casting drum with a surface temperature of 25°C by electrostatic casting method to cool and solidify. This unstretched film was heated to 95° C. and stretched 2.1 times in the longitudinal direction to form a uniaxially stretched film. Both surfaces of ...

Embodiment 2~ Embodiment 18

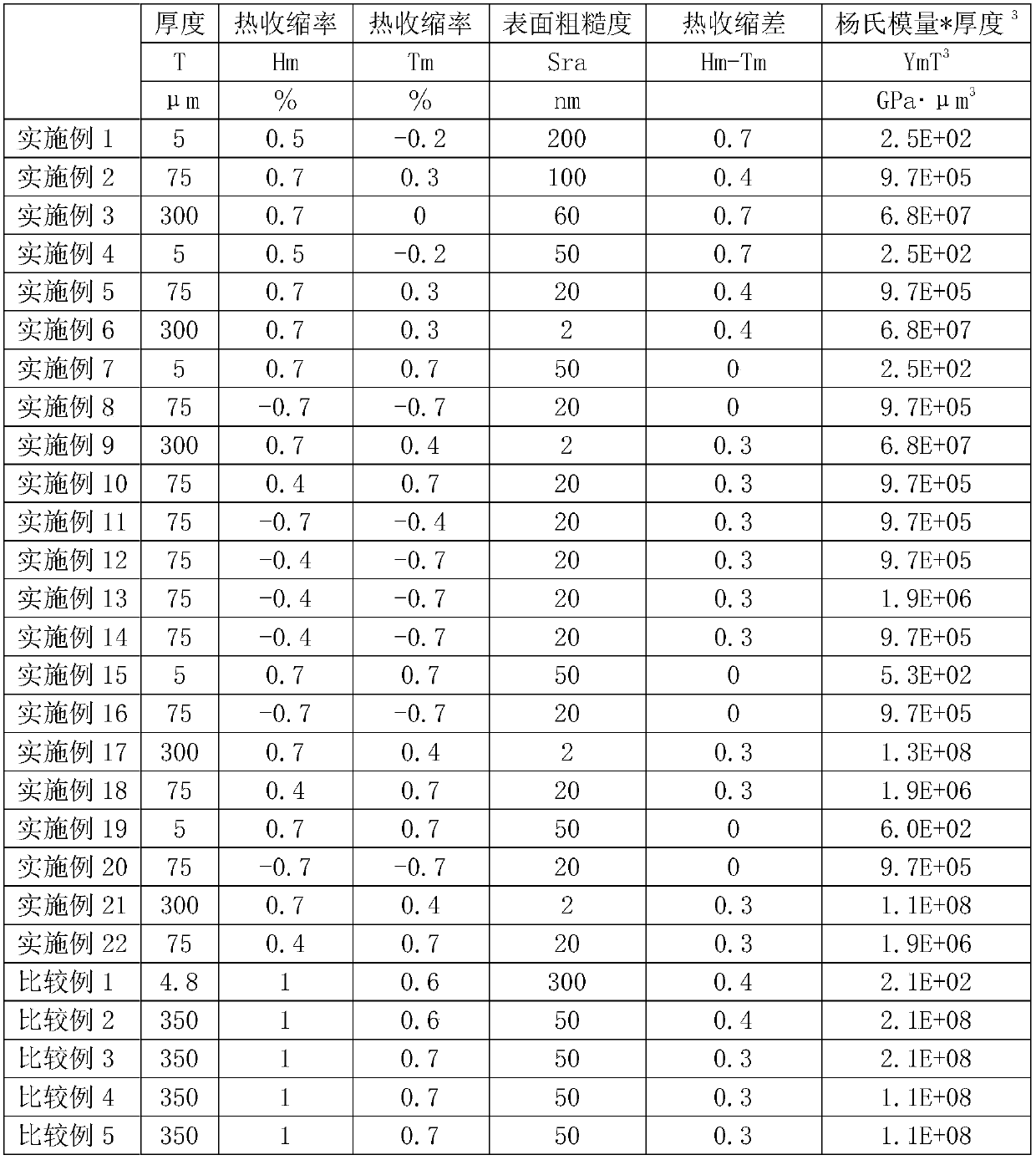

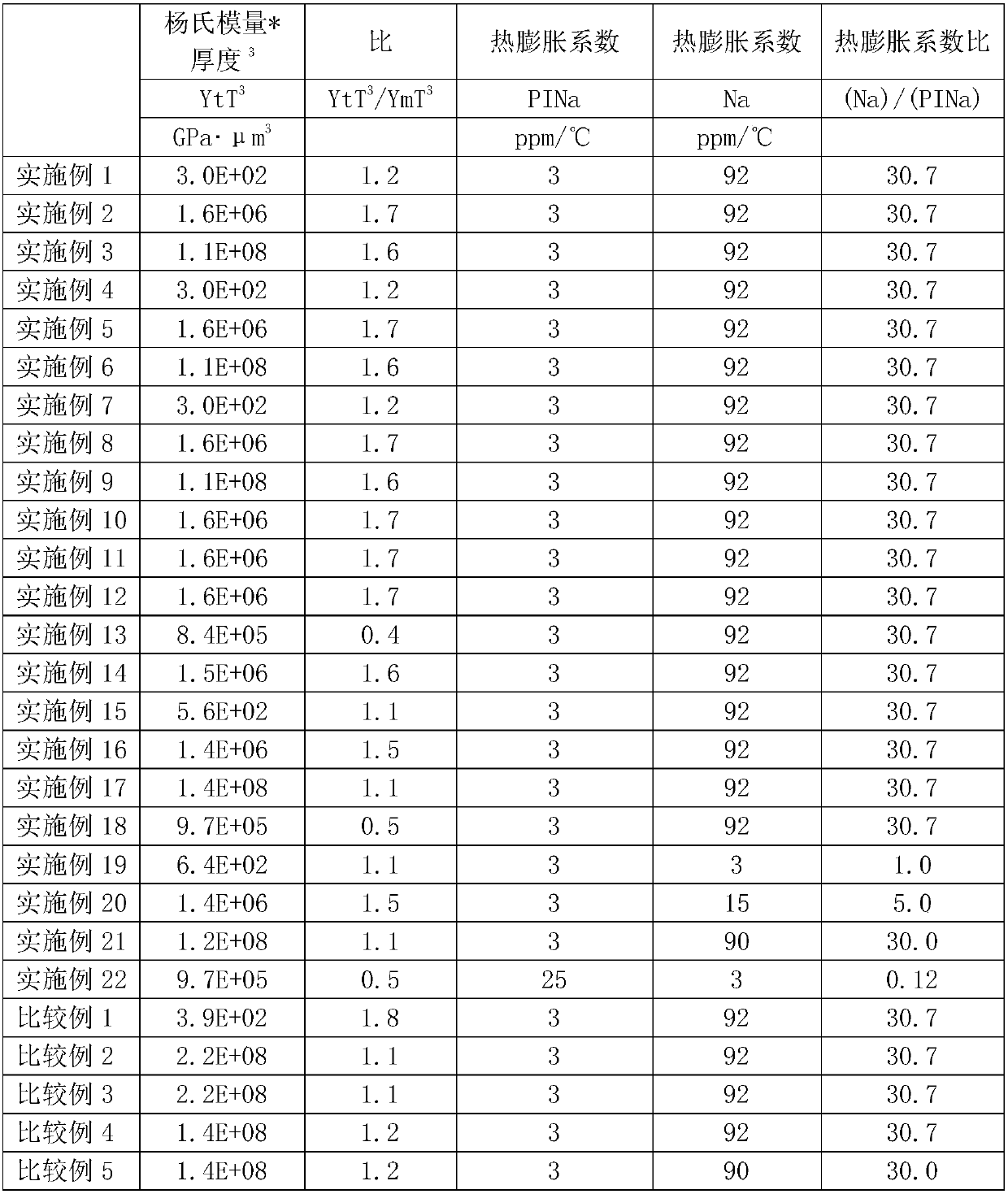

[0158] A PET film was obtained in the same manner as in Example 1 except that the production conditions of the PET film were as described in the table. Next, an adhesive layer film and an organic EL light-emitting film were obtained by the same method as in Example 1 using the obtained PET film.

[0159] The evaluation characteristics in the process of obtaining the organic EL film and the evaluation characteristics of the organic EL light-emitting film are shown in the table.

Embodiment 19

[0161] Prepare pyromellitic dianhydride (molecular weight 218.12) / 3,3',4,4'-biphenyltetracarboxylic dianhydride (molecular weight 294.22) / 4,4' in molar ratio 94 / 6 / 87 / 13 -diaminodiphenyl ether (molecular weight 200.24) / p-phenylenediamine (molecular weight 108.14), polymerized as a 19% by weight solution in DMAC (N,N-dimethylacetamide) to obtain 3500 poise at 25°C Polyamic acid solution. After adding β-picoline and acetic anhydride to the polyamic acid solution so that the molar ratio relative to the polyamic acid becomes 4.5, the ratio of the support body speed / discharge nozzle discharge speed is 5.0, and the support The rotation speed of the body is set to 15m / min, and the wave pressure on the side of the rotation direction of the support body is set to 400Pa higher than the wave pressure on the opposite side. Cast on the support body to obtain a self-supporting polyimide gel membrane.

[0162] The gel film was peeled off continuously from the support, stretched 1.2 times in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com