Preparation method and use of black brushed composite film

A composite film and wire-drawing technology, which is applied in the field of black wire-drawn composite film preparation, can solve the problems that users cannot meet the requirements of beautiful appearance and fine texture, and the appearance color is single, so as to achieve beautiful appearance, strong corrosion resistance and expressive force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

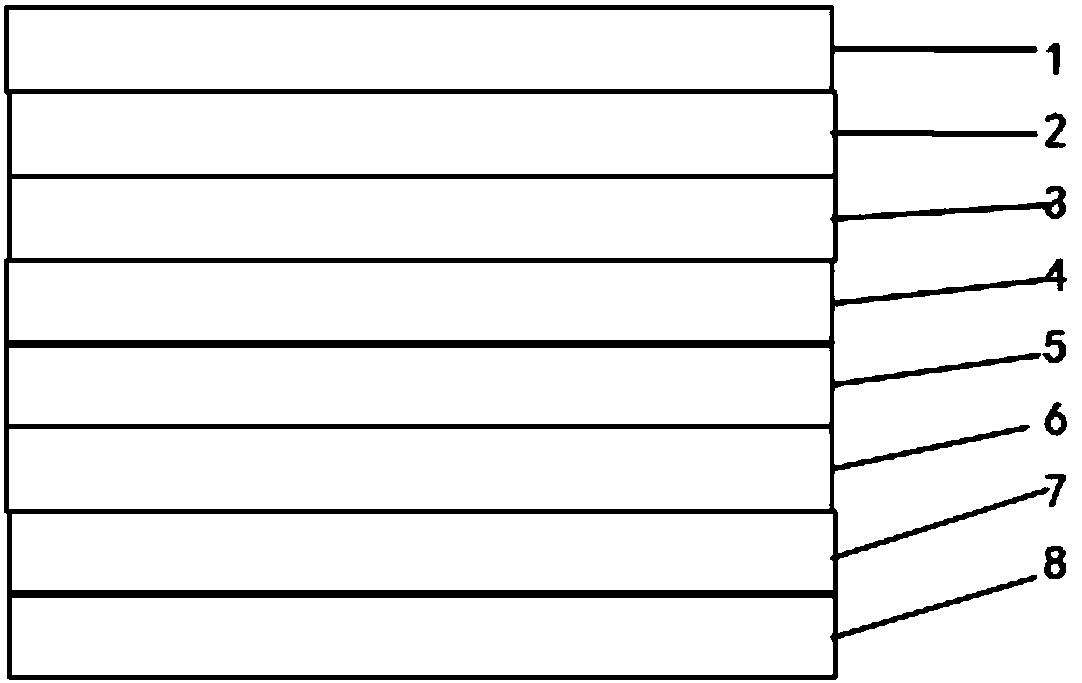

Image

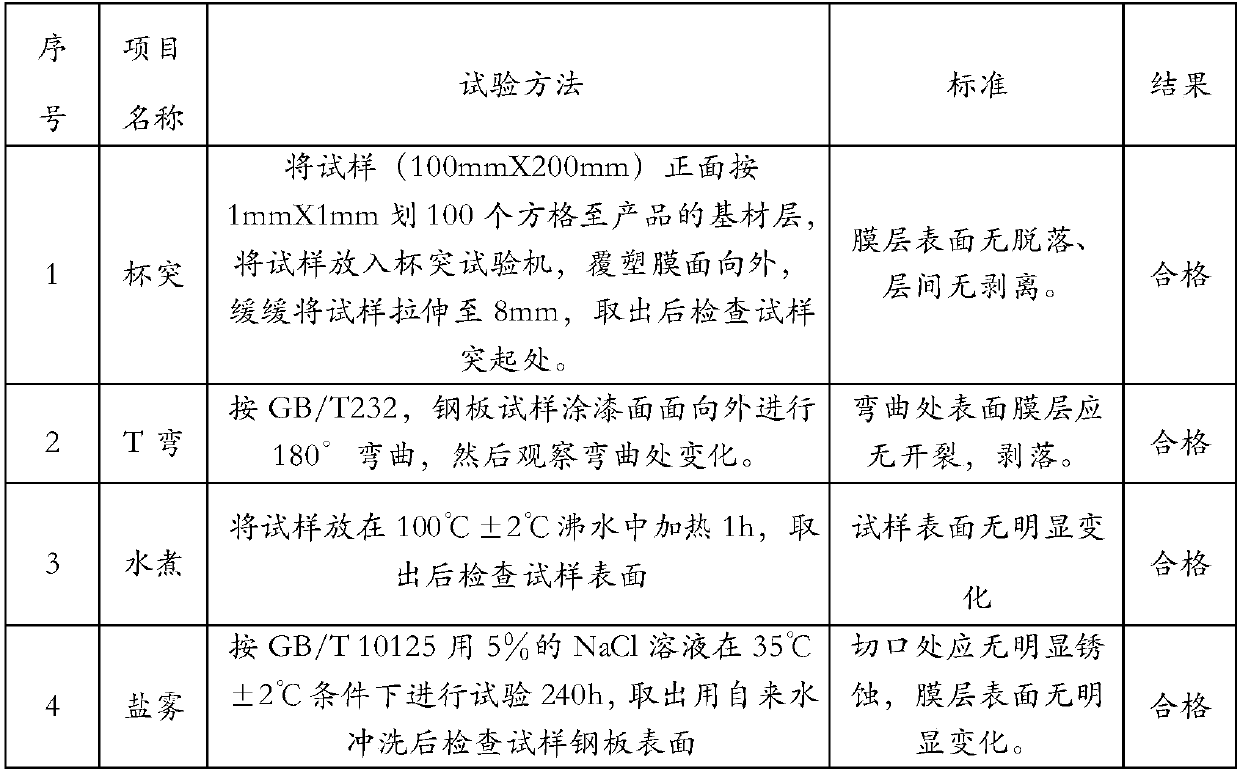

Examples

Embodiment 1

[0024] 1. Preparation of PET wire drawing film

[0025] ①Take a roll of PET film, and the PET base film is purchased from Toray, Korea. Light transmittance: 92%, the level is optical grade, the thickness is 25μm, and the width is 1250mm. Use precision coating equipment to coat a layer of adhesion promoter on the surface of PET. The selected accelerator is a solvent-based accelerator with a solid content of 20 %, the thickness is 1μm, and it has good adhesion with UV glue.

[0026] ②: Use sophisticated UV transfer molding equipment to produce and prepare drawing PET film, select special UV glue, and buy it from Zhejiang An Ruisen Company. The mold is a special self-made vertical grain drawing mold. The molding temperature is controlled at 50°C, and the production line speed is controlled at 10m / min.

[0027] ③: The thickness of the UV-drawn layer of the prepared drawn PET film is 6 μm, the hardness is 2H, and the drawing touch is obvious.

[0028] 2. Preparation of composite...

Embodiment 2

[0043] 1. Preparation of PET wire drawing film

[0044] ①Take a roll of PET film, and the PET base film is purchased from Toray, Korea. Light transmittance: 92%, the grade is optical grade, the thickness is 50μm, and the width is 1250mm. Use precision coating equipment to coat a layer of adhesion promoter on the surface of PET. The selected accelerator is a solvent-based accelerator with a solid content of 20 %, the thickness is 1μm, and it has good adhesion with UV glue.

[0045] ②: Use sophisticated UV transfer molding equipment to produce and prepare drawing PET film, select special UV glue, and buy it from Zhejiang An Ruisen Company. The mold is a special self-made horizontal grain drawing mold. The molding temperature is controlled at 35°C, and the production line speed is controlled at 6m / min.

[0046] ③: The thickness of the UV-drawn layer of the prepared drawn PET film is 8 μm, the hardness is H, and the drawing touch is obvious.

[0047] 2. Preparation of composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com