One main crystal phase is li 2 sio 3 Fluoride-doped oxygen-nitrogen glass-ceramics and preparation method thereof

A technology of glass-ceramic and main crystal phase, applied in the field of material science, to achieve the effect of good fracture toughness, excellent mechanical properties and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

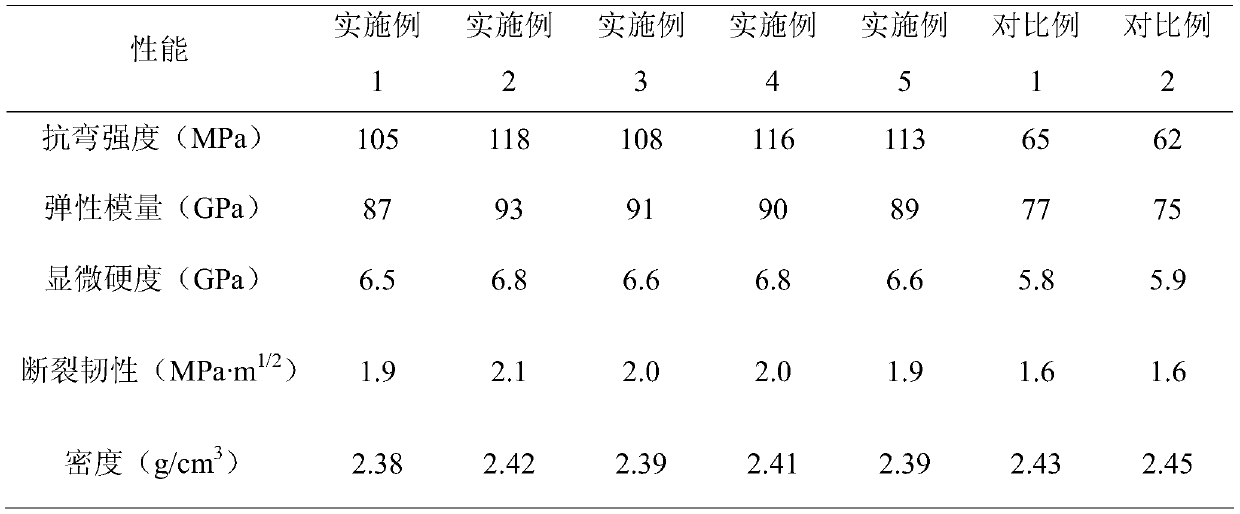

Embodiment 1

[0038] A kind of main crystal phase that present embodiment design is Li 2 SiO 3 Fluoride-doped oxynitride glass-ceramics, the base glass includes the following oxides or nitrides in molar percentages: SiO 2 : 62.0, Li 2 O: 33.0, CaF 2 : 2.5, Si 3 N 4 : 2.5.

Embodiment 2

[0040] A kind of main crystal phase that present embodiment design is Li 2 SiO 3 Fluoride-doped oxynitride glass-ceramics, the base glass includes the following oxides or nitrides in molar percentages: SiO 2 : 58.0, Li 2 O: 35.0, CaF 2 : 4.0, Si 3 N 4 : 3.0.

Embodiment 3

[0042] A kind of main crystal phase that present embodiment design is Li 2 SiO 3 Fluoride-doped oxynitride glass-ceramics, the base glass includes the following oxides or nitrides in molar percentages: SiO 2 : 60.0, Li 2 O: 34.0, CaF 2 : 3.0, Si 3 N 4 : 3.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com