Imitated-agate ceramic glass

A glass-ceramic and agate technology, which is applied in the field of agate-like glass-ceramics, can solve the problems of limited quantity of natural agate, high market price, poor processability, etc., achieve lower product prices, improve thermal stability, and be easy to process and shape Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

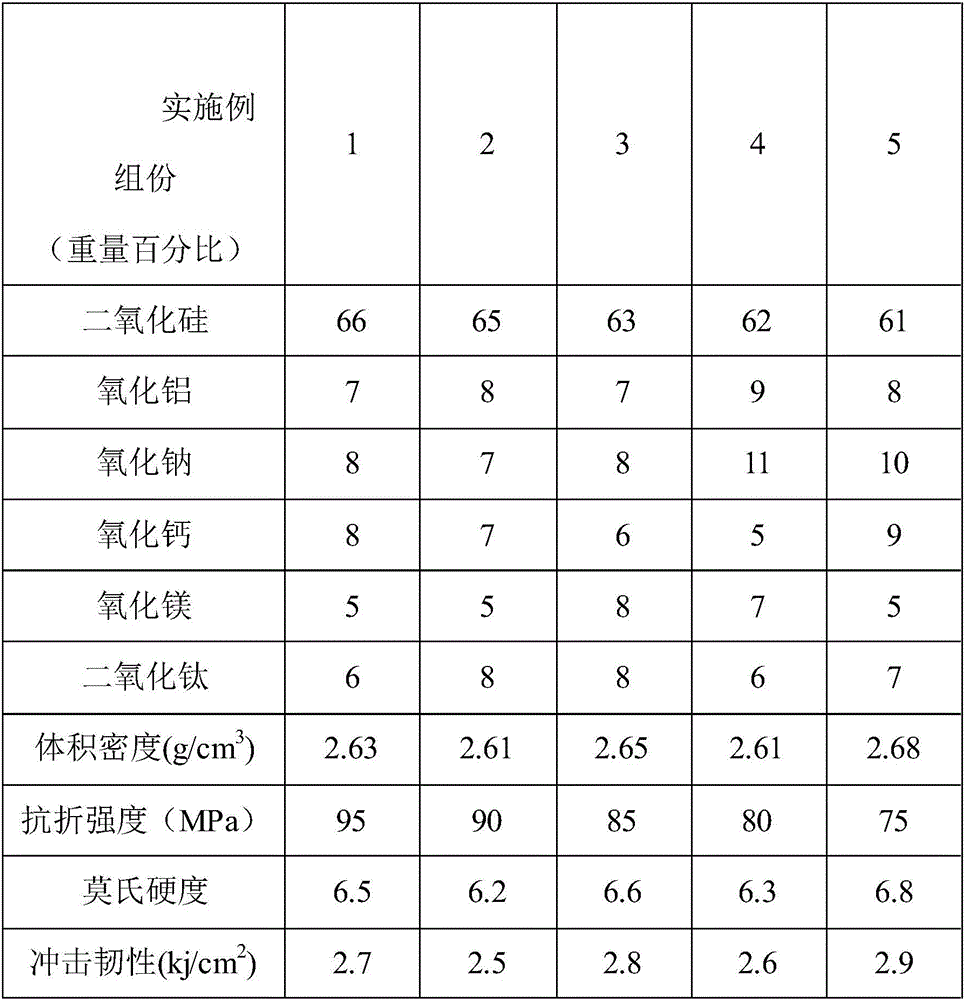

Examples

Embodiment 6

[0022] Embodiment 6: silicon dioxide 65%, aluminum oxide 8%, sodium oxide 7%, calcium oxide 8%, magnesium oxide 5%, titanium dioxide 7%. Bulk density (g / cm 3 ) is 2.66, the flexural strength is 92, the Mohs hardness is 6.7, and the impact toughness is 2.9.

Embodiment 7

[0023] Embodiment 7: The described glass-ceramic comprises the following components by weight percentage: 64% of silicon dioxide, 7% of aluminum oxide, 6% of sodium oxide, 9% of calcium oxide, 6% of magnesium oxide and 8% of titanium dioxide. Bulk density (g / cm 3 ) is 2.67, the flexural strength is 95, the Mohs hardness is 7, and the impact toughness is 2.9.

Embodiment 8

[0024] Embodiment 8: The described glass-ceramic comprises the following components by weight percentage: 62% of silicon dioxide, 6% of aluminum oxide, 8% of sodium oxide, 9% of calcium oxide, 6% of magnesium oxide and 9% of titanium dioxide. Bulk density (g / cm 3 ) is 2.68, the flexural strength is 92, the Mohs hardness is 7, and the impact toughness is 3.

[0025] Prepare the materials according to the above embodiment, and then crush the prepared various raw materials into particles with a particle size of 10-20 meshes, and then use a vertical mixer to mix them evenly for 10-35 minutes to obtain the batch materials; after that, put the batch materials in After high temperature melting at 1500-1580 ℃ in the glass melting furnace, the glass liquid is obtained; then the glass liquid is made into micropowder with a particle size of 2-50 mesh, and then the fine powder is made into particles with a particle size of 2-5 mesh and put into the mold; Put the mold with particles into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com