Portland fly-ash cement and preparation method thereof

A technology of Portland cement and sulfoaluminate cement is applied in the field of cement to achieve the effects of reduced production cost, good grindability and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

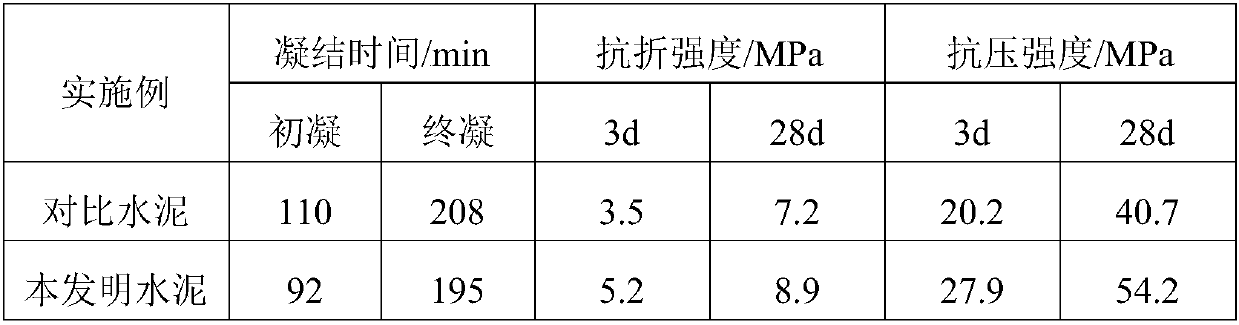

[0032] A preparation method of fly ash Portland cement, the specific implementation steps are as follows: Portland cement clinker, fly ash, calcium sulfosilicate, and dihydrate gypsum are mixed according to the following mass ratio: Portland cement clinker Mix 60 parts of raw materials, 28 parts of fly ash, 7 parts of calcium sulfosilicate, and 5 parts of dihydrate gypsum, and grind them together until the fineness is less than 10% on a 200-mesh sieve to make cement products. According to the national standard GB1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method" GB / T17671-1999 "Cement Strength Test Method", respectively test the setting time of cement and mortar strength, the measurement results are as follows:

[0033]

Embodiment 2

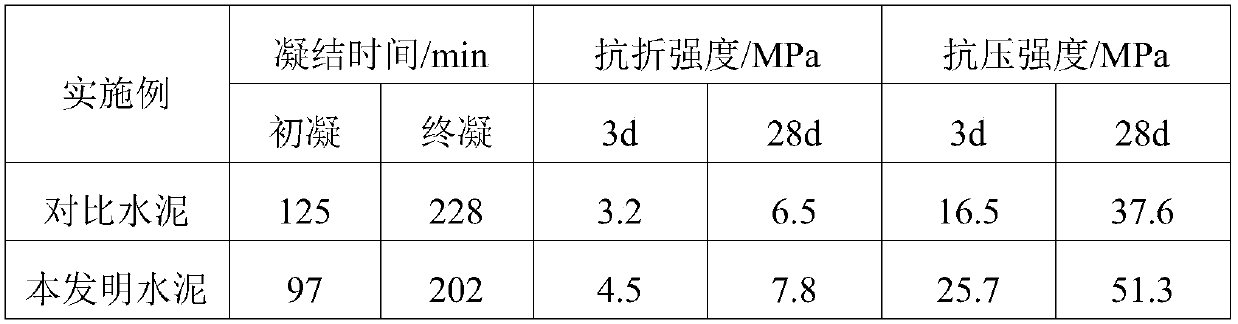

[0035]A preparation method of fly ash Portland cement, the specific implementation steps are as follows: Portland cement clinker, fly ash, calcium sulfosilicate, and dihydrate gypsum are mixed according to the following mass ratio: Portland cement clinker 54 parts of raw materials, 33 parts of fly ash, 9 parts of calcium sulfosilicate, and 4 parts of dihydrate gypsum are mixed evenly and then ground together until the fineness is less than 10% of the 200-mesh sieve to make cement products. According to the national standard GB1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method" GB / T17671-1999 "Cement Strength Test Method", respectively test the setting time of cement and mortar strength, the measurement results are as follows:

[0036]

Embodiment 3

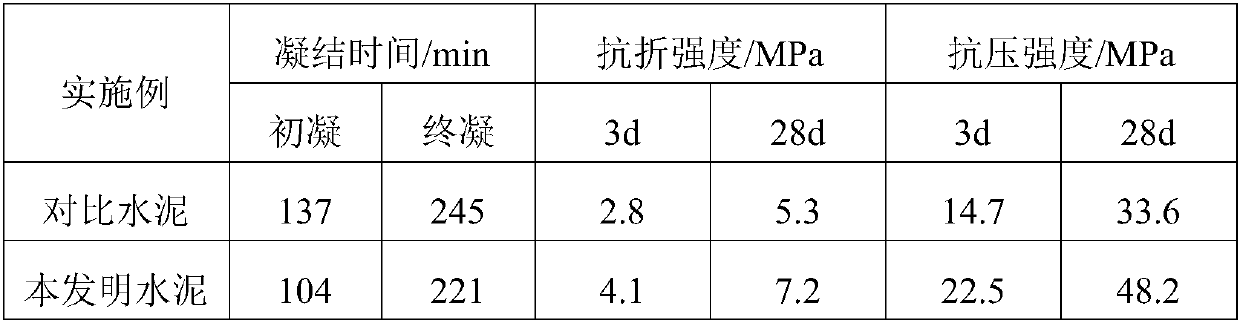

[0038] A preparation method of fly ash Portland cement, the specific implementation steps are as follows: Portland cement clinker, fly ash, calcium sulfosilicate, and dihydrate gypsum are mixed according to the following mass ratio: Portland cement clinker 46 parts of raw materials, 40 parts of fly ash, 12 parts of calcium sulfosilicate, and 2 parts of dihydrate gypsum are mixed evenly and then ground together until the fineness is less than 10% of the 200-mesh sieve to make cement products. According to the national standard GB1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, Stability Test Method" GB / T17671-1999 "Cement Strength Test Method", respectively test the setting time of cement and mortar strength, the measurement results are as follows:

[0039]

[0040] By comparing each embodiment with the blank group without adding calcium sulfosilicate and the same amount of fly ash, it can be seen that the setting time of the fly ash Portland cement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com