Preparation method of celadon

A technology of celadon and blank material, applied in the field of celadon preparation, can solve the problems of low yield, high cost, unsuitable for mass production, etc., and achieve the effect of low cost, less crystal defects, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

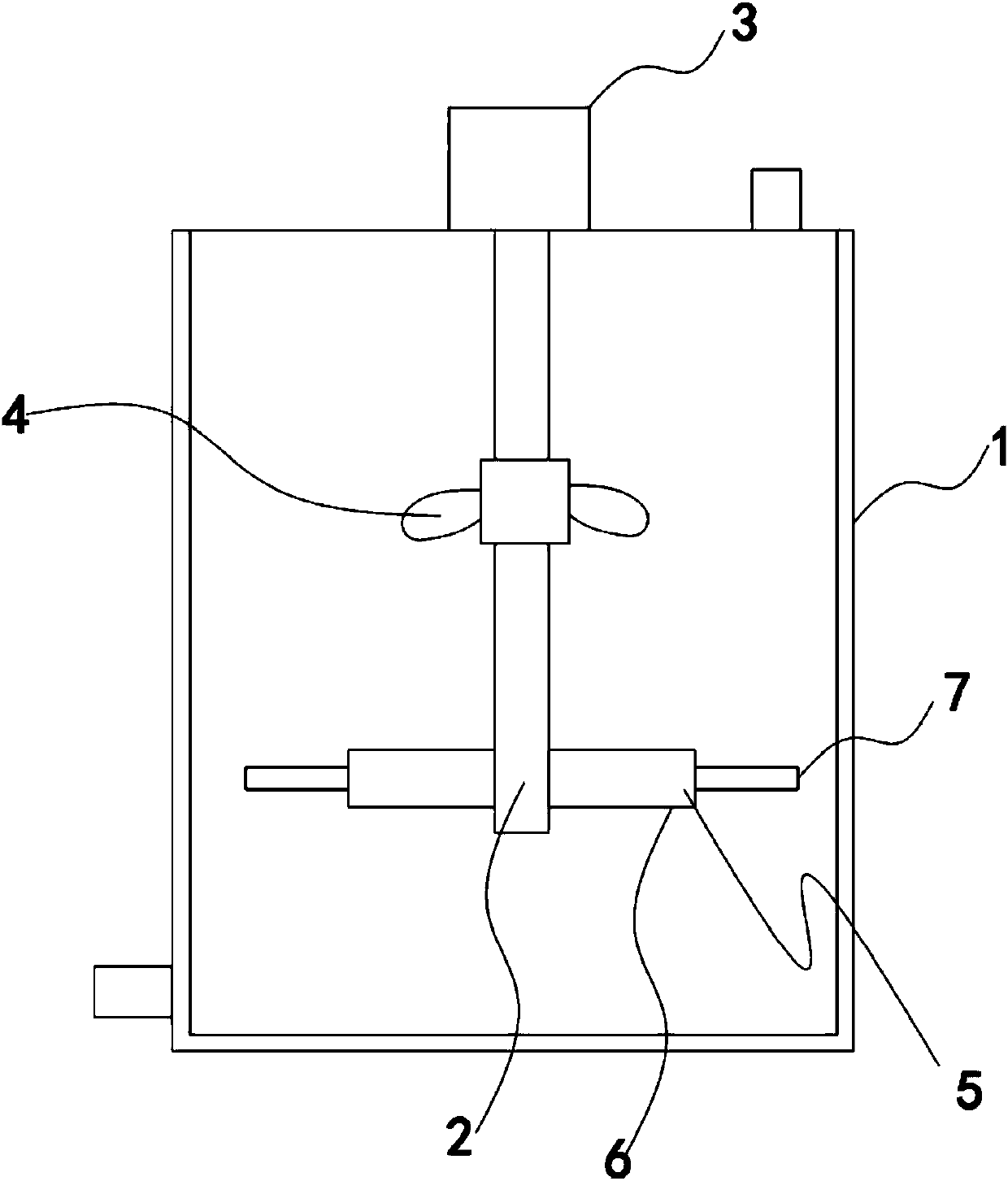

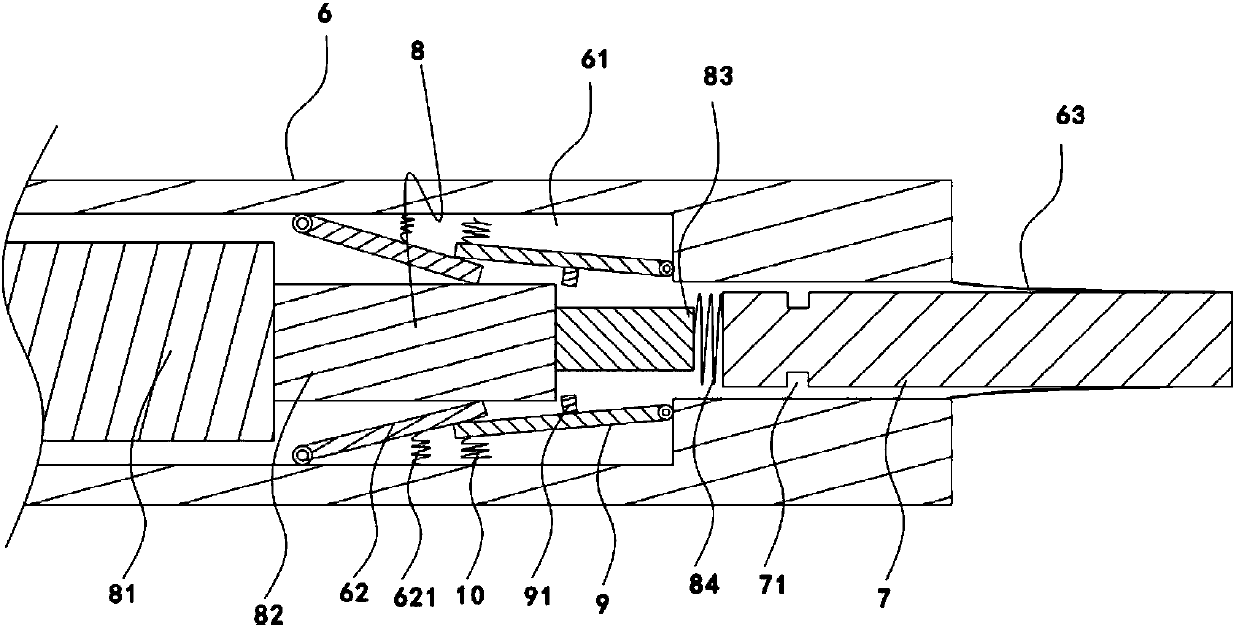

[0022] A kind of preparation method of celadon, described celadon adopts mineral raw material and macromolecule material to prepare blank and glaze, and described blank comprises component A, component B and component C, and described preparation method comprises the following steps: S1: Preparation of component A, component B and component C; S2: Slurry preparation of blank material; S3: Embryo body molding; S4: Blank firing of embryo body; S5: Glaze preparation of glaze material; S6: Upper Glaze; S7: glaze firing.

[0023]Specifically, the preparation of component A in the S1 step includes drying and crushing 115 parts of kaolin, 18 parts of cooked talc, 28 parts of dolomite and 16 parts of high alumina bauxite in parts by weight, and then Put it into a ball mill for ball milling until it passes through a 500-mesh sieve; the preparation of component B includes drying and crushing 45 parts of quartz, 16 parts of magnesite and 44 parts of calcite respectively in parts by weigh...

Embodiment 2

[0036] A kind of preparation method of celadon, described celadon adopts mineral raw material and macromolecule material to prepare blank and glaze, and described blank comprises component A, component B and component C, and described preparation method comprises the following steps: S1: Preparation of component A, component B and component C; S2: Slurry preparation of blank material; S3: Embryo body molding; S4: Blank firing of embryo body; S5: Glaze preparation of glaze material; S6: Upper Glaze; S7: glaze firing.

[0037] Specifically, the preparation of Component A in the S1 step includes drying and crushing 120 parts of kaolin, 20 parts of cooked talc, 30 parts of dolomite, and 20 parts of high alumina bauxite respectively by weight and number, and then Put it into a ball mill for ball milling until it passes through a 500-mesh sieve; the preparation of component B includes drying and grinding 50 parts of quartz, 20 parts of magnesite, 50 parts of calcite and 10 parts of ...

Embodiment 3

[0047] A kind of preparation method of celadon, described celadon adopts mineral raw material and macromolecule material to prepare blank and glaze, and described blank comprises component A, component B and component C, and described preparation method comprises the following steps: S1: Preparation of component A, component B and component C; S2: Slurry preparation of blank material; S3: Embryo body molding; S4: Blank firing of embryo body; S5: Glaze preparation of glaze material; S6: Upper Glaze; S7: glaze firing.

[0048] Specifically, the preparation of component A in the S1 step includes drying and crushing 115 parts of kaolin, 18 parts of cooked talc, 28 parts of dolomite, and 16 parts of high alumina bauxite respectively by weight and number, and then Put it into a ball mill for ball milling until it passes through a 500-mesh sieve; the preparation of component B includes drying and crushing 45 parts of quartz, 16 parts of magnesite and 44 parts of calcite respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com