Biomass carbonization device and biochar preparation process

A biomass charcoal and preparation process technology, applied in the fields of biofuel, petroleum industry, special forms of dry distillation, etc., can solve the problems of poor continuous dry distillation effect and poor quality of dry distillation products, avoid high content of harmful components, realize automation and simplification The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

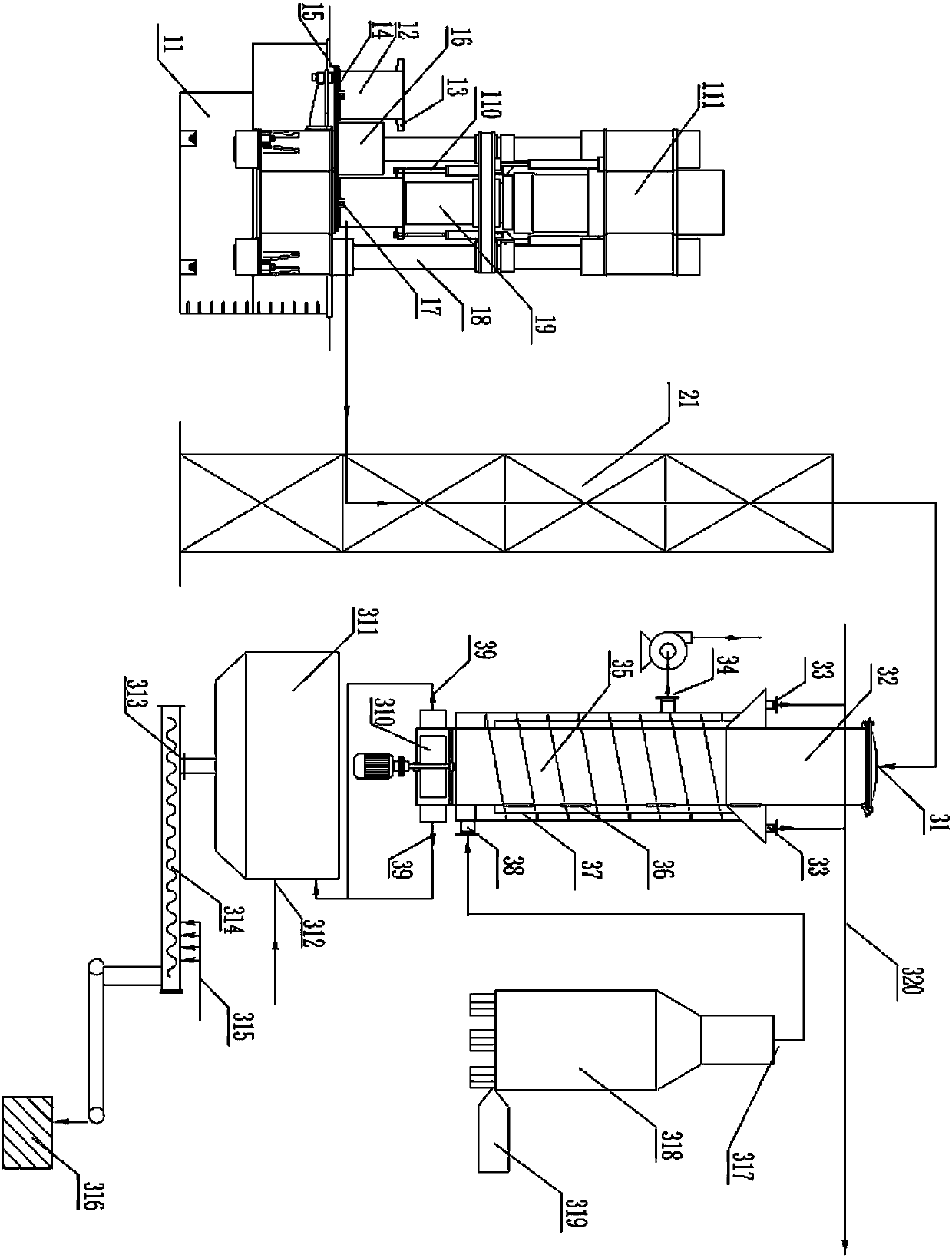

[0041] This embodiment provides a biomass carbonization device, such as figure 1 As shown, including: for briquetting biomass, a biomass briquette system for obtaining biomass briquettes, a biomass briquette carbonization system for carbonizing biomass briquettes, and a biomass briquette carbonization system for briquetting biomass The briquettes are conveyed from the biomass briquette system to the biomass briquette delivery system of the biomass briquette carbonization system.

[0042] The biomass briquetting system includes: a loading unit, a briquetting unit and at least one first feeding unit; the first feeding unit is located above the loading unit, and the loading unit rotates the loaded first feeding unit The material unit is sent to the briquetting unit for biomass briquetting.

[0043] As an embodiment of the present invention, specifically, the loading unit includes: a rotary table 15 arranged on the base 11, a drive shaft 16 arranged at the rotation center of the ...

Embodiment 2

[0065] This embodiment provides a method for preparing biochar using the biomass carbonization device described in Embodiment 1, comprising the following steps:

[0066] S1. Load the dried biomass with a moisture content of 8% to 20% and a temperature of 25° C. to 100° C. into the mold sleeve 12 on the rotary table 15 . As an embodiment of the present invention, in this embodiment, the moisture content of the biomass block is 15%, and the temperature is 60°C.

[0067] S2. The rotary table 15 is rotated, and the mold sleeve 12 containing the biomass material is sent to the position of the pressing part 19 for stamping, the pressure is 5Mpa-40Mpa, and the pressing speed is 0.1t / h-2t / h; After the specified pressure is reached and the stroke of the pressurizing part 19 remains unchanged, the pressure is maintained for 10s-60s. As an embodiment of the present invention, in this embodiment, the stamping pressure is 20 MPa, the pressing speed is 1 t / h, and the holding time is 35 s. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com