Novel weft accumulator of water-jet/air-jet loom

An air-jet loom and weft accumulator technology, which is applied in looms, textiles, textiles and paper making, etc., can solve the problems of complicated mechanism and process, weft damage in the working condition of the weft accumulator, etc. Reduced, stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

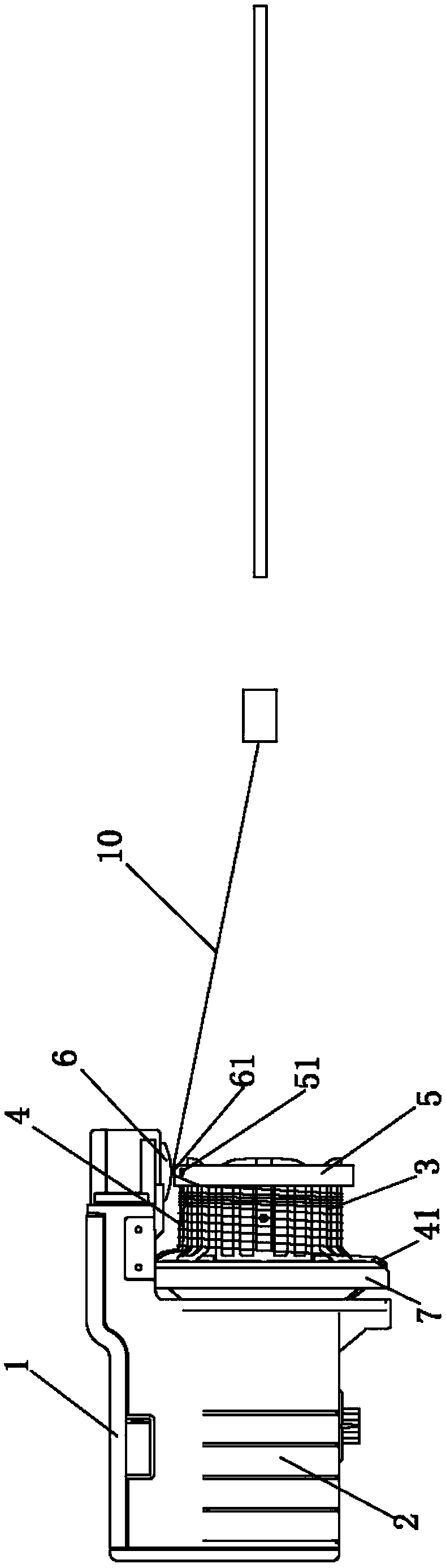

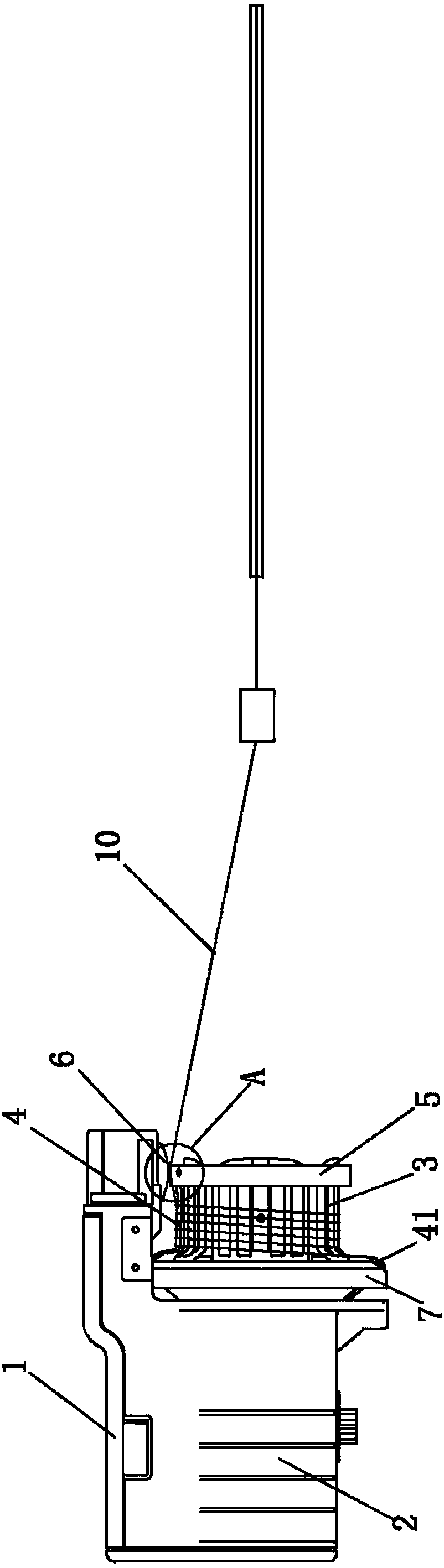

[0019] Please refer to the attached figure 1 to attach Figure 8 As shown, the present invention is a novel water-jet / air-jet loom weft feeder, which is used to store and transport weft yarn 10, and consists of a housing 1, a weft storage control motor 2, a yarn drum 3, a yarn discharge body 4, The yarn coil 5, the electromagnetic needle 6 and the winding frame 7 are composed of several parts.

[0020] Wherein, the weft storage control motor 2 is installed on the housing 1, which is connected and drives the winding frame 7 to rotate.

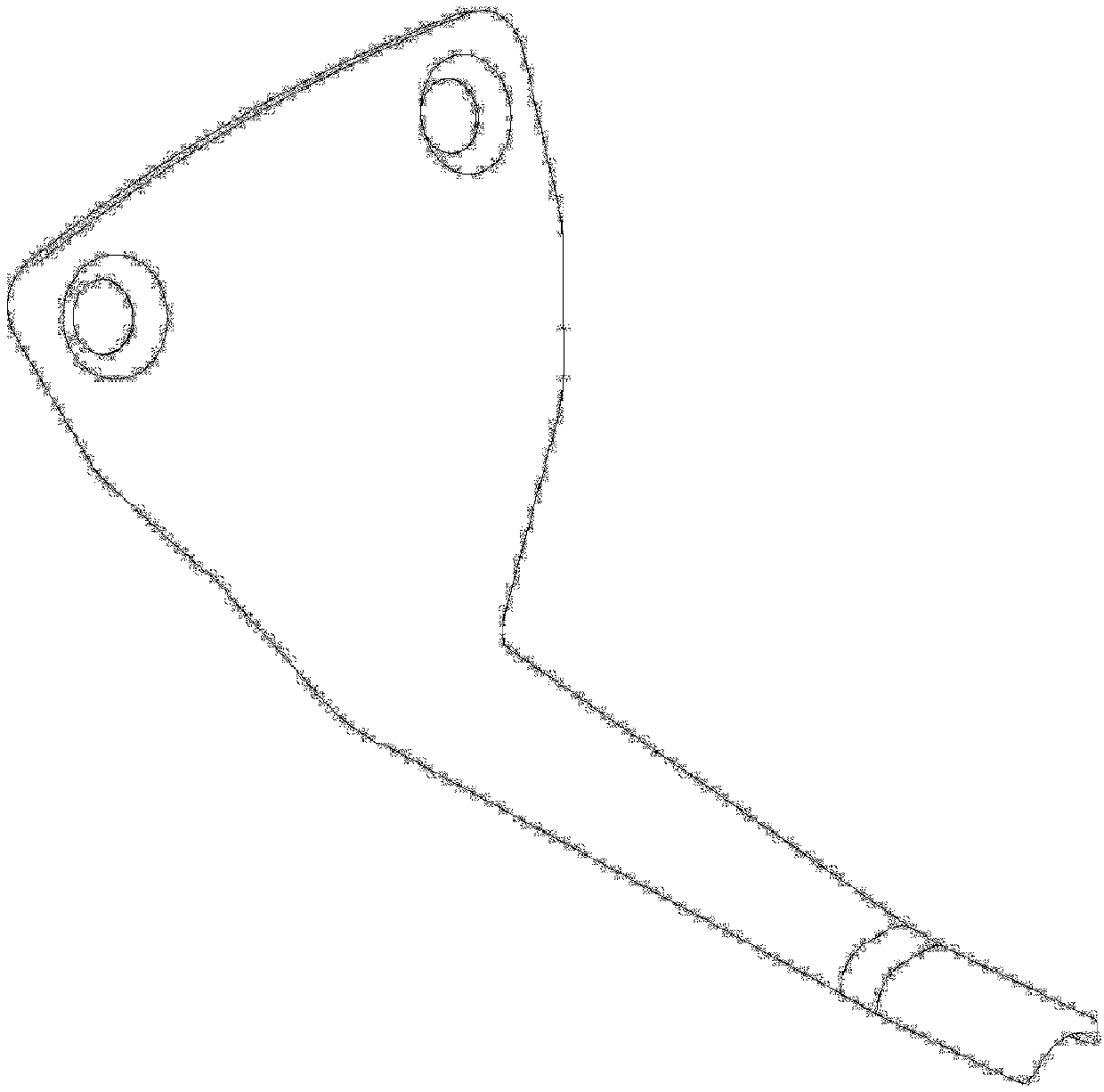

[0021] Said yarn-discharging body 4 is installed on the yarn winding frame 7, and it is arranged obliquely towards the axial direction of the yarn winding frame 7. The weft yarn 10 is wound on the yarn-discharging body 4 and the yarn drum 3 at intervals in sequence. The front end of the yarn-discharging body 4 is upturned horizontally, thereby preventing the weft yarn 10 from slipping out of the yarn-discharging body 4 .

[0022] Please refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com