Application of molybdenum-containing alloy in concentrated sulfuric acid cooler

A technology of concentrated sulfuric acid and molybdenum alloy, which is applied to the types of heat exchangers, heat exchanger shells, indirect heat exchangers, etc., can solve the problems of high water quality requirements, waste of water resources, and the inability to use chlorine-containing sulfuric acid, etc., to improve the resistance Corrosiveness, water saving, and the effect of reducing cooling water replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

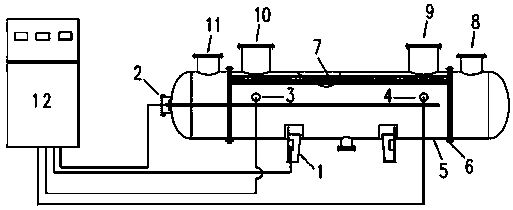

[0021] Embodiment 1, with reference to figure 1 , the concentrated sulfuric acid cooler of the present invention is a shell-and-tube heat exchanger, the tube-side medium is cooling water, the shell-side medium is concentrated sulfuric acid, and the cooling water and concentrated sulfuric acid are exchanged through heat exchange tube bundles to achieve the purpose of cooling concentrated sulfuric acid .

[0022] The concentrated sulfuric acid cooler is equipped with an anode protection device, which is composed of: the heat exchange tube bundle 7, the tube plate 6, and the cylinder body 5 of the cooler are used as anodes, and one or several parallel tubes are arranged in the middle of the heat exchange tube bundle 7 The connected cathode 2 has an insulating sleeve; the cylinder 5 of the cooler is insulated and sealed with a control reference electrode 3 and a monitoring reference electrode 4; the anode, the cathode 2, the control reference electrode 3, and the monitoring refere...

Embodiment 2

[0032] Example 2, the structure of the concentrated sulfuric acid distributor, concentrated sulfuric acid pipeline, concentrated sulfuric acid tank and anode protection device made of molybdenum-containing alloy can adopt the structure disclosed in the existing patent documents ZL01124947.1, ZL02154414.X, ZL201010572825.2 or The structure commonly used in the prior art, when the main parts in this structure are made of molybdenum-containing alloy, the sulfuric acid concentration range that can be used on the acid side of the equipment: 90% to 100%, and the usable temperature range: 70°C to 120°C , the equipment corrosion rate is ≤0.1mm / year, the service life of the concentrated sulfuric acid cooler is ≥8 years, which is equivalent to or better than the existing concentrated sulfuric acid equipment; the requirement for the content of chloride ions on the acid side is greatly reduced, and the concentration range of chloride ions in the concentrated sulfuric acid is 0 ~0.05%.

Embodiment 3

[0033] Embodiment 3, the oleum cooler, oleum evaporator, oleum distributor, oleum tank or oleum pipeline structure and the anode protection device configured by the molybdenum-containing alloy can all adopt the existing A structure commonly used in technology. When the main parts of the structure are made of molybdenum-containing alloys, the equipment is on the acid side, the concentration range of fuming sulfuric acid that can be used is 100% to 120%, the temperature range that can be used is 70°C to 200°C, and the corrosion rate of the equipment ≤0.1 mm / year, the service life of the oleum cooler is ≥8 years, which is equivalent to or better than the existing niacin equipment; the requirements for the content of chloride ions on the acid side and water side are greatly reduced, and the concentration range of chloride ions in oleum 0-0.05%; the applicable concentration range of chloride ions in cooling water is: 0.05%-15%, cooling water and industrial sewage with highly concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com