Method for preparing micro-expansion graphite material by mixture of scale graphite and microcrystal graphite

A technology of flake graphite and microcrystalline graphite, which is applied in the field of material preparation, can solve problems such as poor expansion effect of microcrystalline graphite, hindered application of lithium-ion electrode negative electrode materials, and reduced capacitance, so as to improve the intercalation effect, efficiency, and reserves Great, Inexpensive Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

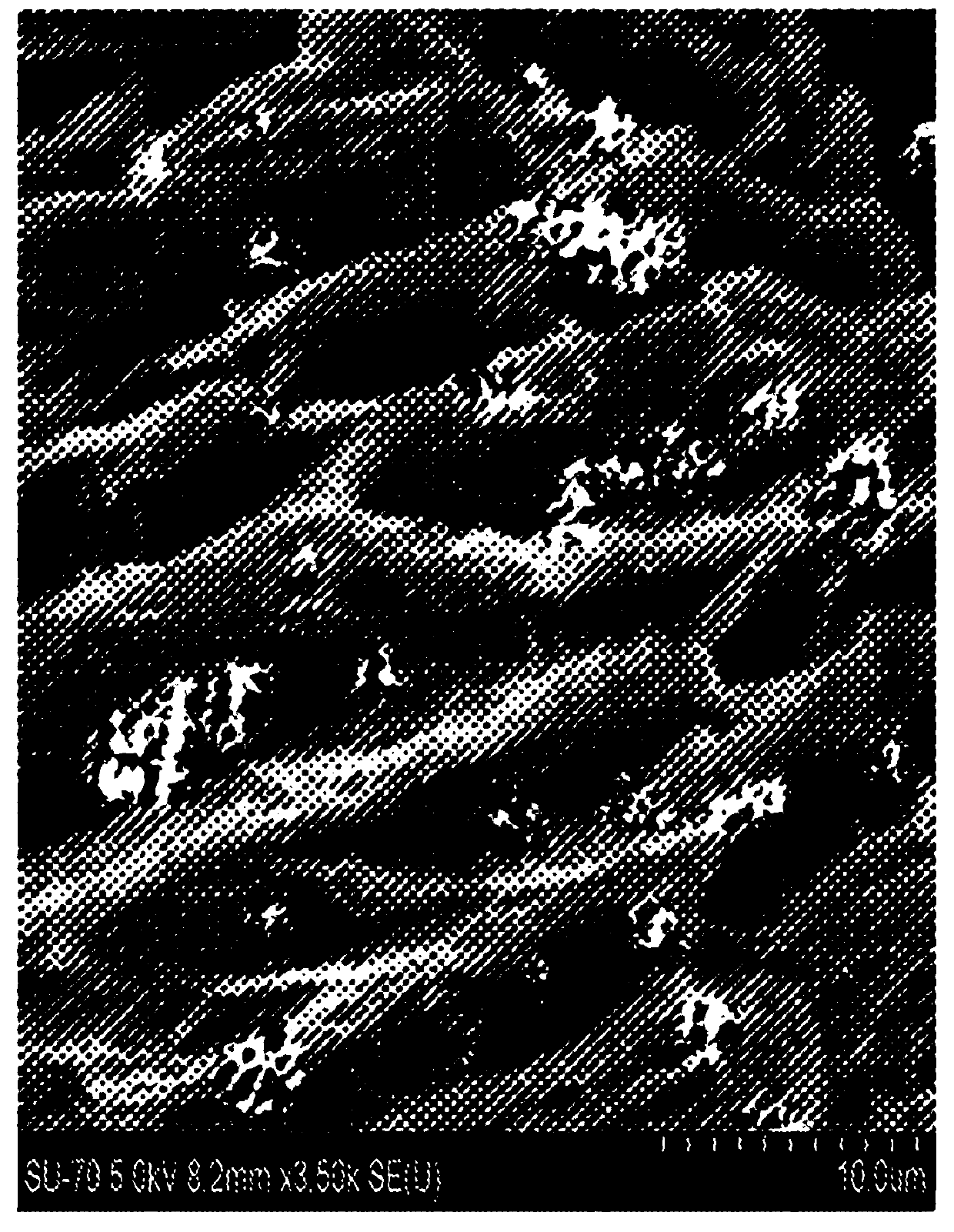

Image

Examples

Embodiment 1

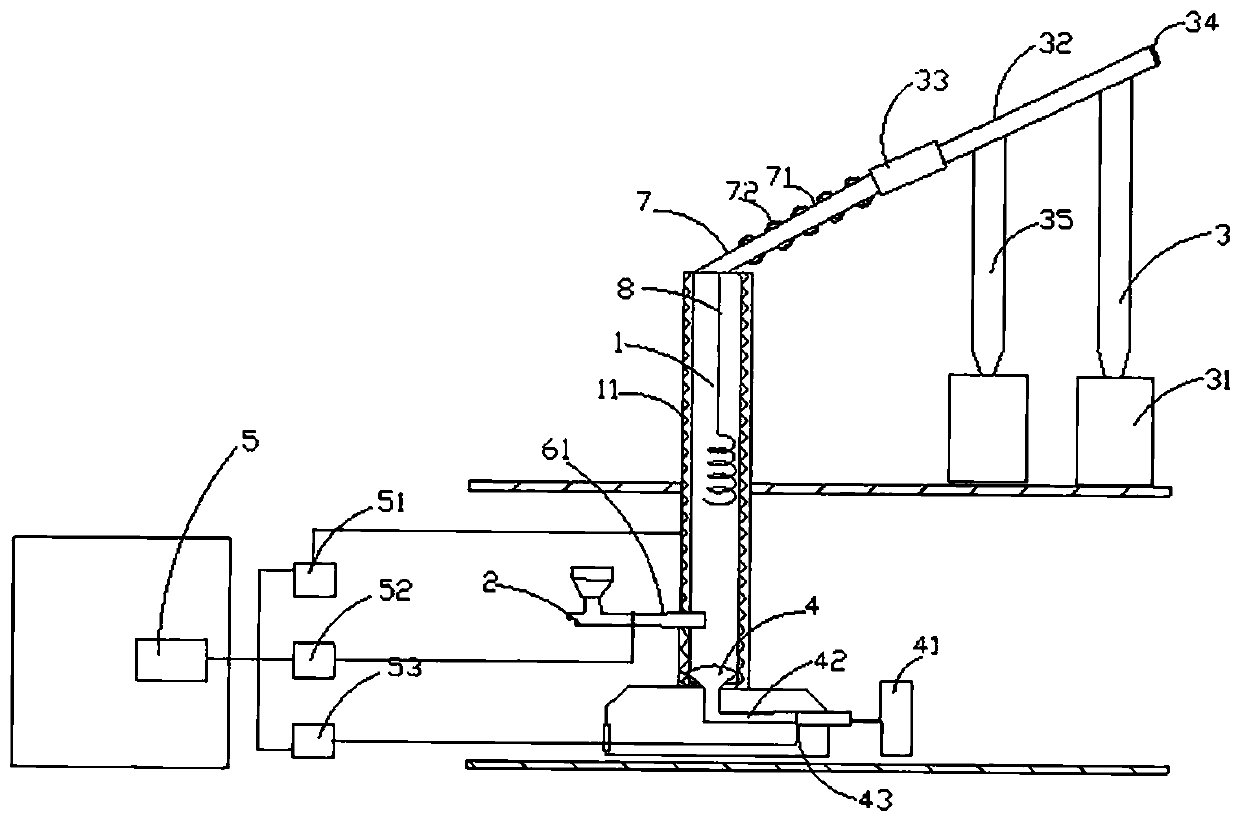

[0041] The present invention prepares the micro-expanded graphite material by mixing microcrystalline graphite and flake graphite, comprising the following steps: comprising a graphite expansion furnace, adopting a high-temperature expansion method, comprising the following steps:

[0042] S1. Take microcrystalline graphite raw materials with 70% carbon content and flake graphite raw materials with 85% carbon content. The mass ratio of flake graphite and microcrystalline graphite is 2:1, crush and grind until the particle size is 300 mesh mixed graphite powder.

[0043] S2. Put the mixture obtained in S1 in a muffle furnace, slowly raise the temperature to 350° C. under a nitrogen atmosphere, keep it warm for 30 minutes, and air-cool to room temperature for later use.

[0044] S3. Carry out chemical intercalation treatment to the mixture after S2 heat treatment to obtain expandable mixed graphite, wherein the specific steps of chemical intercalation treatment are as follows:

...

Embodiment 2

[0050] The present invention prepares the micro-expanded graphite material by mixing microcrystalline graphite and flake graphite, comprising the following steps: comprising a graphite expansion furnace, adopting a high-temperature expansion method, comprising the following steps:

[0051] S1. Get the microcrystalline graphite raw material with carbon content of 75% and the flake graphite raw material with carbon content of 90%, the mass ratio of flake graphite and microcrystalline graphite is 2:1, crush and grind until the particle size is 200 mesh mixed graphite powder;

[0052] S2. Put the mixture obtained in S1 in a muffle furnace, slowly raise the temperature to 400° C. under a nitrogen atmosphere, keep it warm for 10 minutes, and air-cool to room temperature for use.

[0053] S3. Carry out chemical intercalation treatment to the mixture after S2 heat treatment to obtain expandable mixed graphite, wherein the specific steps of chemical intercalation treatment are as follow...

Embodiment 3

[0059] The present invention prepares the micro-expanded graphite material by mixing microcrystalline graphite and flake graphite, comprising the following steps: comprising a graphite expansion furnace, adopting a high-temperature expansion method, comprising the following steps:

[0060] S1. Get microcrystalline graphite raw material with carbon content of 75% and flake graphite raw material with carbon content of 85%, the mass ratio of flake graphite and microcrystalline graphite is 2.5:1, crushing and grinding, until particle size is 200 mesh mixed graphite powder;

[0061] S2. Put the mixture obtained in S1 in a muffle furnace, slowly raise the temperature to 400° C. under a nitrogen atmosphere, keep it warm for 10 minutes, and air-cool to room temperature for use.

[0062] S3. Carry out chemical intercalation treatment to the mixture after S2 heat treatment to obtain expandable mixed graphite, wherein the specific steps of chemical intercalation treatment are as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com