Production method of healthy monosodium glutamate

A production method and technology of monosodium glutamate, applied to the functions of food ingredients, food ingredients containing inorganic compounds, food science, etc., can solve the problems of not feeling the fun and enjoyment of food, and achieve the goals of avoiding oxidation, improving efficiency, and relieving high blood pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

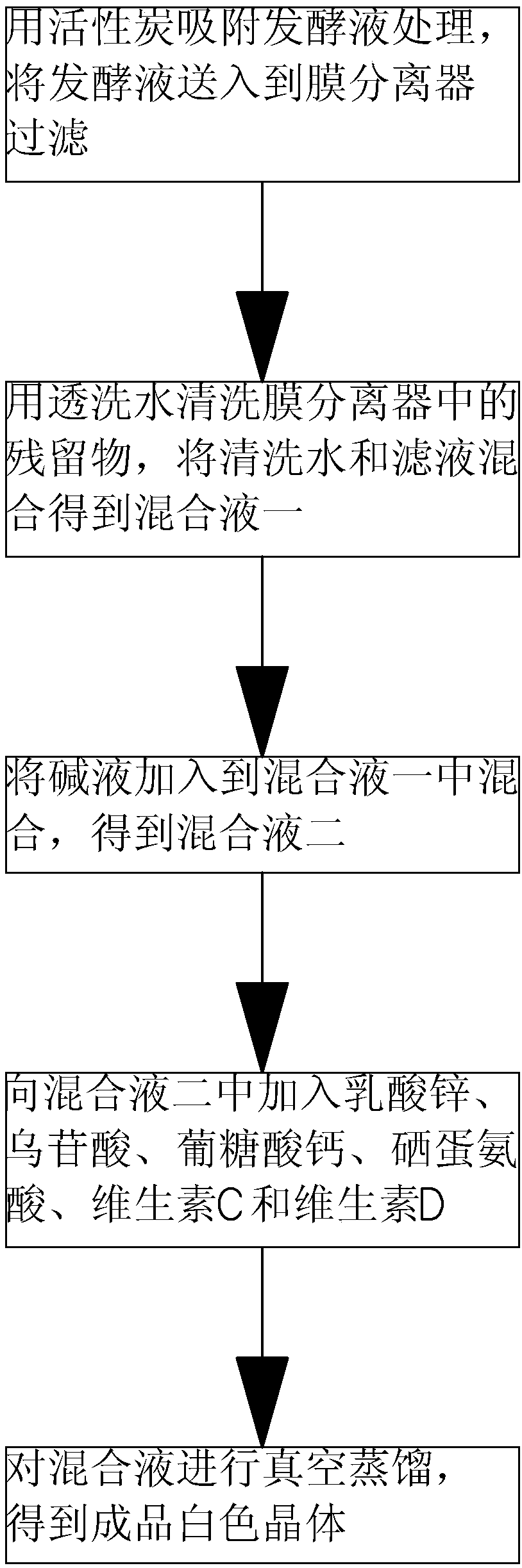

[0035] The production steps of healthy monosodium glutamate:

[0036] Step 1: Add activated carbon to the fermentation broth containing glutamic acid or ammonium glutamate for adsorption treatment, then heat it to 60°C, send it to a membrane separator for filtration, and remove the mycelium, solid protein and colloid in the fermentation broth Stopped in the membrane separator to obtain 68Kg of filtrate;

[0037] Step 2: Cleaning the residue remaining in the membrane separator with permeable washing water, and mixing the cleaning water with the filtrate obtained in step 1 to obtain a mixed solution 1;

[0038] Step 3: Weigh 100Kg of lye mixed with sodium hydroxide and potassium hydroxide and slowly add it to the mixed solution 1 of step 2, and keep stirring at a stirring speed of 100 rpm, wherein the hydroxide concentration of the lye is 0.1 mol / L, detect the pH value of mixed solution with pH tester simultaneously, until pH value is 7, stop adding lye, obtain mixed solution 2...

Embodiment 2

[0043] The production steps of healthy monosodium glutamate:

[0044] Step 1: Add activated carbon to the fermentation broth containing glutamic acid or ammonium glutamate for adsorption treatment, then heat it to 70°C, send it to a membrane separator for filtration, and remove the mycelium, solid protein and colloid in the fermentation broth Stopped in the membrane separator to obtain 68Kg of filtrate;

[0045] Step 2: Cleaning the residue remaining in the membrane separator with permeable washing water, and mixing the cleaning water with the filtrate obtained in step 1 to obtain a mixed solution 1;

[0046] Step 3: Weigh 100Kg of lye mixed with sodium hydroxide and potassium hydroxide and slowly add it to the mixed solution 1 of step 2, and keep stirring at a stirring speed of 100 rpm, wherein the hydroxide concentration of the lye is 0.1 mol / L, detect the pH value of mixed solution with pH tester simultaneously, until pH value is 7, stop adding lye, obtain mixed solution 2...

Embodiment 3

[0051] The production steps of healthy monosodium glutamate:

[0052] Step 1: Add activated carbon to the fermentation broth containing glutamic acid or ammonium glutamate for adsorption treatment, then heat it to 65°C, send it to a membrane separator for filtration, and remove the mycelium, solid protein and colloid in the fermentation broth Stopped in the membrane separator to obtain 68Kg of filtrate;

[0053] Step 2: Cleaning the residue remaining in the membrane separator with permeable washing water, and mixing the cleaning water with the filtrate obtained in step 1 to obtain a mixed solution 1;

[0054] Step 3: Weigh 100Kg of lye mixed with sodium hydroxide and potassium hydroxide and slowly add it to the mixed solution 1 of step 2, and keep stirring at a stirring speed of 100 rpm, wherein the hydroxide concentration of the lye is 0.1 mol / L, detect the pH value of mixed solution with pH tester simultaneously, until pH value is 7, stop adding lye, obtain mixed solution 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com