Vitamin E nanoemulsion, nano cream and preparation method thereof

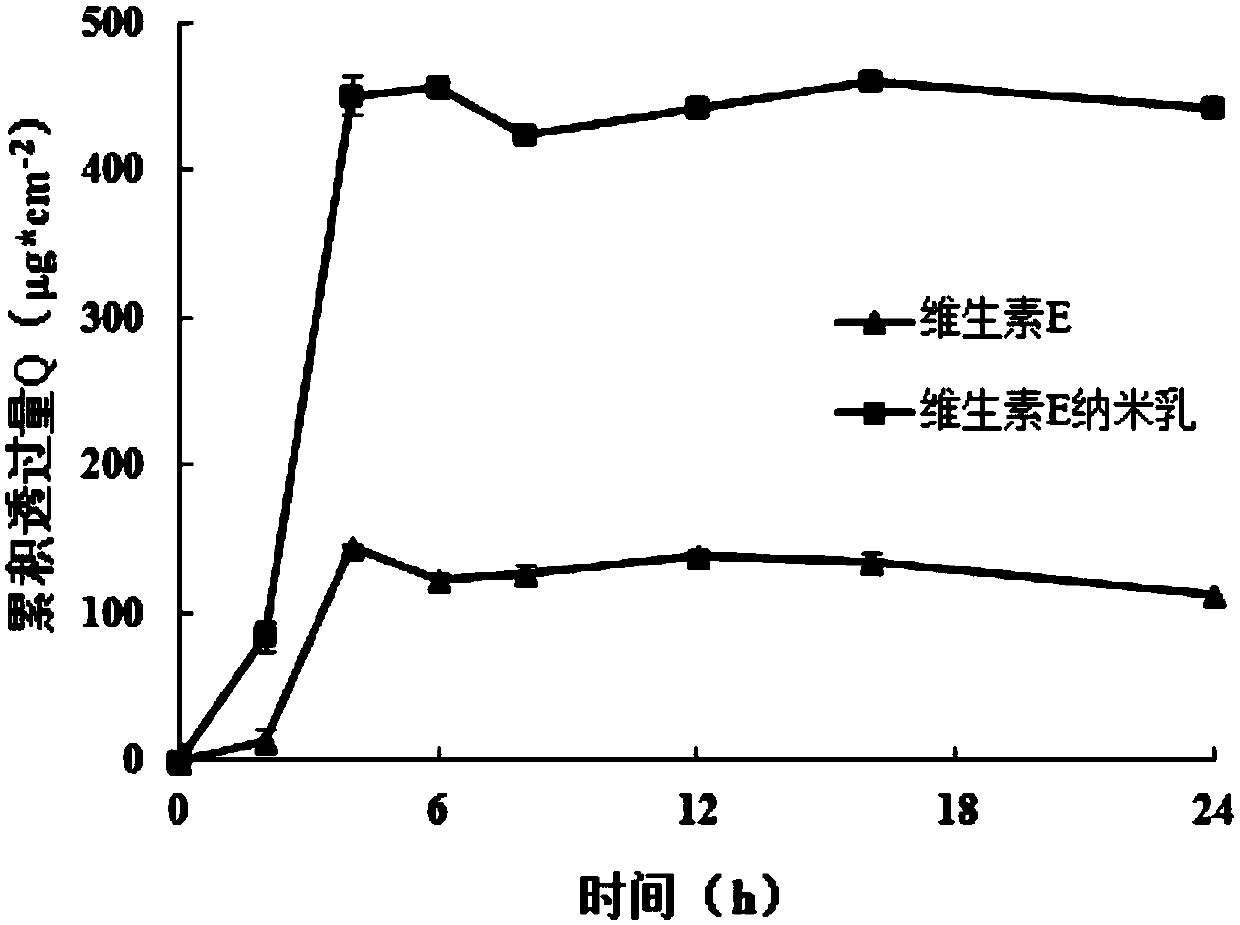

A nano-emulsion and vitamin technology, which is applied in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of poor absorption effect of vitamin E cream, and achieve excellent transdermal penetration ability, environmental friendliness, and distribution range. narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

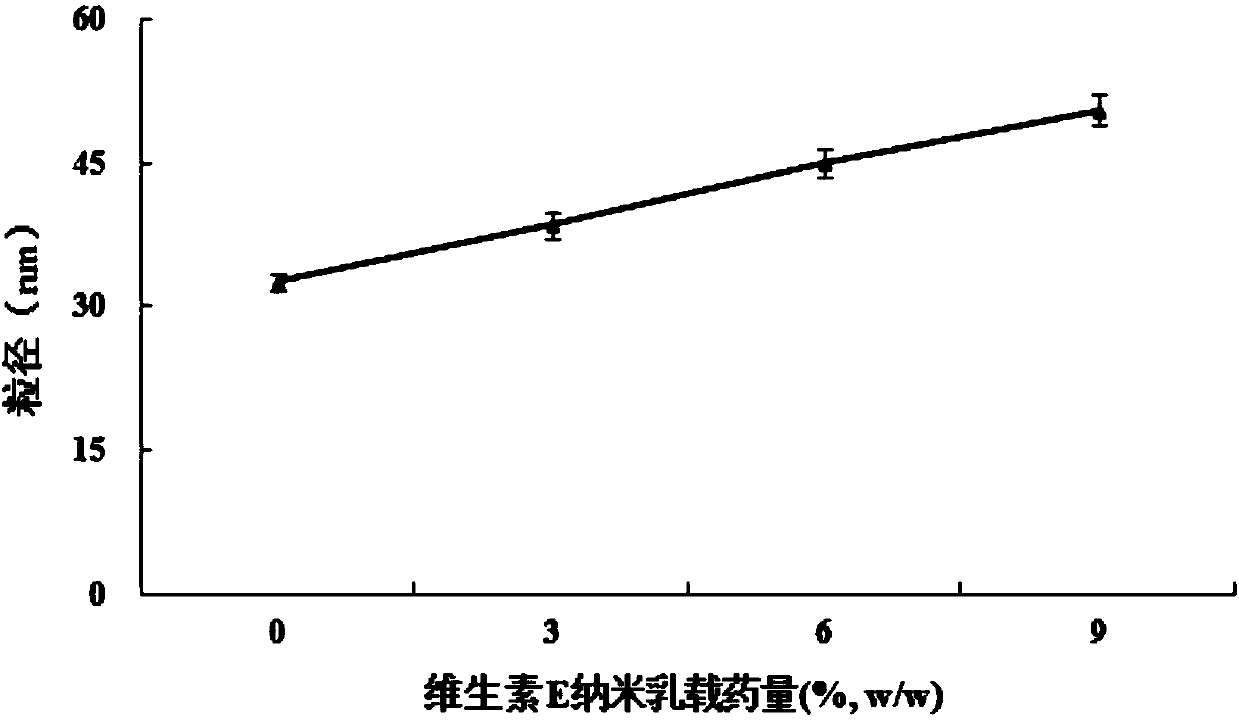

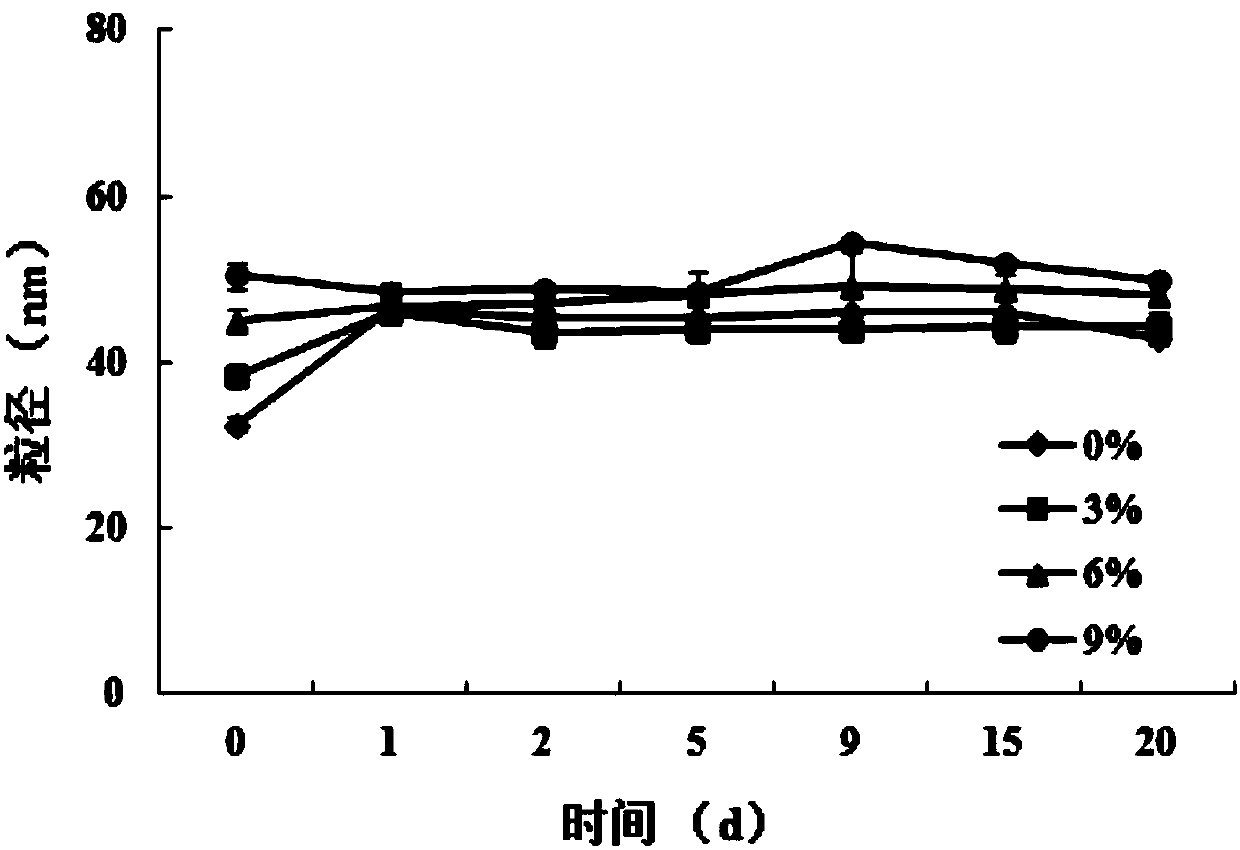

[0041] Example 1 Preparation of Vitamin E Nanoemulsion of 3wt% Vitamin E

[0042] The raw materials of the vitamin E nanoemulsion: 0.0339g vitamin E (pharmaceutical grade, purity ≥ 98.8%, the same below), 0.1560g isopropyl myristate, 0.1050g Span 20, 0.1750g Tween 80, 0.0840g glycerin , 0.6100 g water.

[0043] Wherein, nanoemulsion base: 14% of oil phase, 32% of surfactant, and the balance is water. The vitamin E mass accounts for 3% of the nanoemulsion matrix mass. The mass ratio of the main surfactant (Span 20 and Tween 80) to the co-surfactant (glycerol) was 1:0.3, the HLB value of the main surfactant was 12.6, and the mass ratio of Tween 80 to Span 20 was 1.67:1.

[0044] Preparation method: first add the oil phase (isopropyl myristate) and vitamin E accurately weighed to the required amount, mix and stir evenly; then add the main surfactant (Span and Tween), the auxiliary surfactant agent (glycerin), and stir evenly; then slowly add distilled water drop by drop, and s...

Embodiment 2

[0045] Example 2 Preparation of Vitamin E Nanoemulsion of 6wt% Vitamin E

[0046]The raw materials of the vitamin E nanoemulsion: 0.0678g vitamin E, 0.1560g isopropyl myristate, 0.1050g Span 20, 0.1750g Tween 80, 0.0840g glycerin, 0.6100g water.

[0047] Wherein, nanoemulsion base: 14% of oil phase, 32% of surfactant, and the balance is water. The vitamin E mass accounts for 6% of the nanoemulsion matrix mass. The mass ratio of the main surfactant (Span 20 and Tween 80) to the co-surfactant (glycerol) was 1:0.3, the HLB value of the main surfactant was 12.6, and the mass ratio of Tween 80 to Span 20 was 1.67:1.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0049] Example 3 Preparation of Vitamin E Nanoemulsion of 9wt% Vitamin E

[0050] The raw materials of the vitamin E nanoemulsion: 0.1017g vitamin E, 0.1560g isopropyl myristate, 0.1050g Span 20, 0.1750g Tween 80, 0.0840g glycerin, 0.6100g water.

[0051] Wherein, nanoemulsion base: 14% of oil phase, 32% of surfactant, and the balance is water. The vitamin E mass accounts for 9% of the nanoemulsion matrix mass. The mass ratio of the main surfactant (Span 20 and Tween 80) to the co-surfactant (glycerol) was 1:0.3, the HLB value of the main surfactant was 12.6, and the mass ratio of Tween 80 to Span 20 was 1.67:1.

[0052] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size distribution range | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com