Spliced air purifier filter material combined by multiple materials

A technology for air purifiers and filter materials, applied in chemical instruments and methods, filtration separation, gas treatment, etc., can solve the problems of single material and insufficient adsorption, and achieve good mechanical and physical properties, good protection, and reduce The effect of cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

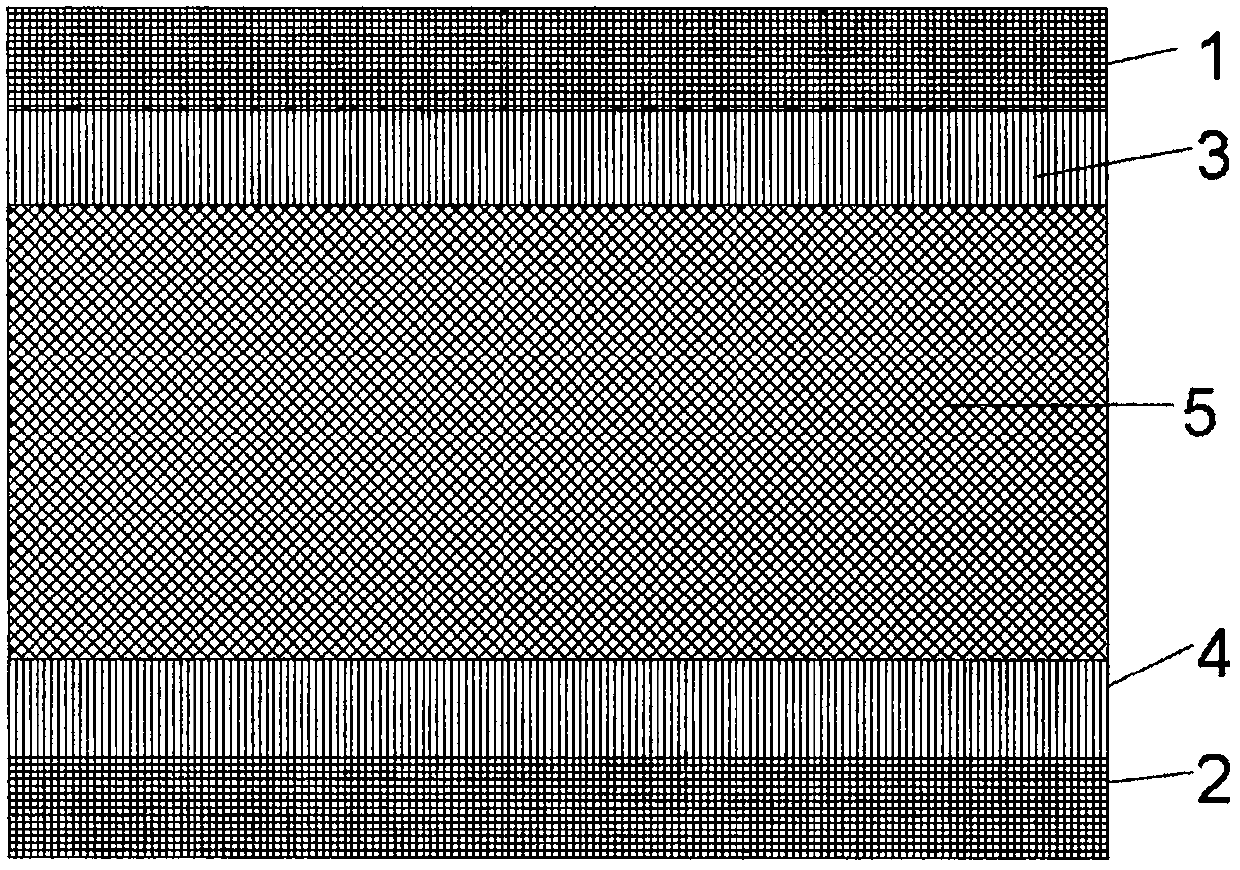

[0025] A spliced air purifier filter material combined with multiple materials, which is a five-layer spliced structure, wherein:

[0026] The outermost two layers are the first layer of graphene nanomaterial adsorption layer (1) and the second layer of graphene nanomaterial adsorption layer (2), wherein the first layer of graphene nanomaterial adsorption layer (1) is the dust-facing surface, The second layer of graphene nanomaterial adsorption layer (2) is the dust outlet surface. The first layer of graphene nanomaterial adsorption layer and the second layer of graphene nanomaterial adsorption layer are formed by stacking graphene nanofiber materials. The diameter is 200nm, and the thickness of the adsorption layer is 200μm;

[0027] The inner two layers are the third layer of biological material chitin adsorption layer (3) and the fourth layer of biological material chitin adsorption layer (4), the third layer of biological material chitin adsorption layer and the fourth...

Embodiment 2

[0034] A spliced air purifier filter material combined with multiple materials, which is a five-layer spliced structure, wherein:

[0035] The outermost two layers are the first layer of graphene nanomaterial adsorption layer (1) and the second layer of graphene nanomaterial adsorption layer (2), wherein the first layer of graphene nanomaterial adsorption layer (1) is the dust-facing surface, The second layer of graphene nanomaterial adsorption layer (2) is the dust outlet surface. The first layer of graphene nanomaterial adsorption layer and the second layer of graphene nanomaterial adsorption layer are formed by stacking graphene nanofiber materials. The diameter is 400nm, and the thickness of the adsorption layer is 250μm;

[0036]The inner two layers are the third layer of biological material chitin adsorption layer (3) and the fourth layer of biological material chitin adsorption layer (4), the third layer of biological material chitin adsorption layer and the fourth ...

Embodiment 3

[0043] A spliced air purifier filter material combined with multiple materials, which is a five-layer spliced structure, wherein:

[0044] The outermost two layers are the first layer of graphene nanomaterial adsorption layer (1) and the second layer of graphene nanomaterial adsorption layer (2), wherein the first layer of graphene nanomaterial adsorption layer (1) is the dust-facing surface, The second layer of graphene nanomaterial adsorption layer (2) is the dust outlet surface. The first layer of graphene nanomaterial adsorption layer and the second layer of graphene nanomaterial adsorption layer are formed by stacking graphene nanofiber materials. The diameter is 800nm, and the thickness of the adsorption layer is 500μm;

[0045] The inner two layers are the third layer of biological material chitin adsorption layer (3) and the fourth layer of biological material chitin adsorption layer (4), the third layer of biological material chitin adsorption layer and the fourth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com