A kind of activation method of fluorination catalyst

A technology of fluorination catalyst and activation method, which is applied in the field of preparation of fluorination catalyst, can solve the problems of destroying the internal structure of the catalyst, affecting the catalytic activity of the catalyst, and not considering the exothermic catalyst of the reaction, so as to avoid damage and achieve high catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

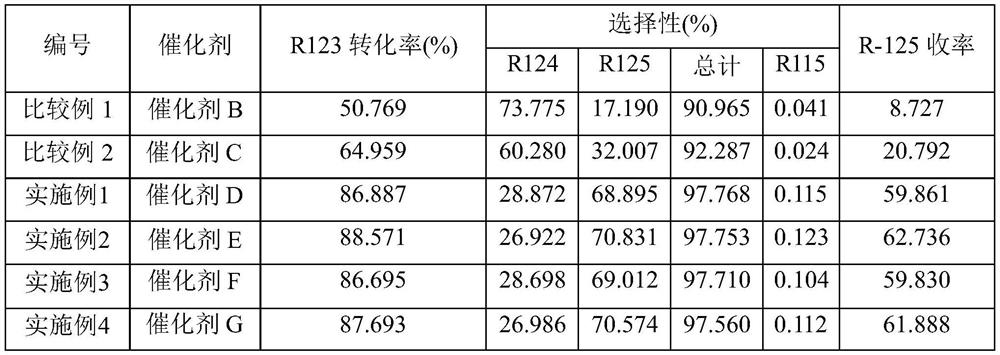

Examples

Embodiment 1

[0065] Drying: Take 80g, about 100mL of catalyst precursor A (composed of chromium oxide, aluminum oxide, magnesium oxide and zinc oxide), fill it into a fixed bed reactor, the whole heating rate is 8°C / min, under nitrogen mass flow In 60g / h atmosphere, dry at 200°C, 300°C and 350°C for 2 hours respectively;

[0066] Initial control: After drying, adjust the mass flow rate of hydrogen fluoride to 36g / h at 240°C and 60g / h nitrogen atmosphere to ensure that △T does not exceed 20°C. If it exceeds 20°C, cut off hydrogen fluoride, and continue to feed when the temperature returns to 240°C Fluorination until hydrogen fluoride can be fed continuously and ΔT does not exceed 20°C;

[0067] Step-by-step activation: 1. Adjust the mass flow rate of hydrogen fluoride to 88g / h and keep it constant, the temperature is 240°C, adjust the mass flow ratio of nitrogen and hydrogen fluoride to 0.8:1 and activate for 2h; 2. Adjust the temperature to 280°C, adjust nitrogen and hydrogen fluoride Act...

Embodiment 2

[0070] Drying: Take 80g, about 100mL of catalyst precursor A (composed of chromium oxide, aluminum oxide, magnesium oxide and zinc oxide), fill it into a fixed bed reactor, the whole heating rate is 8°C / min, under nitrogen mass flow In 60g / h atmosphere, dry at 200°C, 300°C and 350°C for 2 hours respectively;

[0071] Initial control: After drying, adjust the mass flow rate of hydrogen fluoride to 36g / h at 240°C and 60g / h nitrogen atmosphere to ensure that △T does not exceed 20°C. If it exceeds 20°C, cut off hydrogen fluoride, and continue to feed when the temperature returns to 240°C Fluorination until hydrogen fluoride can be fed continuously and ΔT does not exceed 20°C;

[0072] Step-by-step activation: 1. Adjust the mass flow rate of hydrogen fluoride to 88g / h and keep it constant, the temperature is 240°C, adjust the ratio of mass flow rate of nitrogen and hydrogen fluoride to 0.8:1 and activate for 2h; 3. Adjust the temperature to 360°C, adjust the mass flow ratio of nit...

Embodiment 3

[0075] Drying: Take 80g, about 100mL of catalyst precursor A (composed of chromium oxide, aluminum oxide, magnesium oxide and zinc oxide), fill it into a fixed bed reactor, the whole heating rate is 8°C / min, under nitrogen mass flow In 60g / h atmosphere, dry at 200°C, 300°C and 350°C for 2 hours respectively;

[0076] Initial control: After drying, adjust the mass flow rate of hydrogen fluoride to 36g / h at 240°C and 60g / h nitrogen atmosphere to ensure that △T does not exceed 20°C. If it exceeds 20°C, cut off hydrogen fluoride, and continue to feed when the temperature returns to 240°C Fluorination until hydrogen fluoride can be fed continuously and ΔT does not exceed 20°C;

[0077] Step-by-step activation: 1. Adjust the mass flow rate of hydrogen fluoride to 40g / h and keep it constant, the temperature is 240°C, adjust the mass flow ratio of nitrogen and hydrogen fluoride to 0.8:1 and activate for 2h; 2. Adjust the temperature to 280°C, adjust nitrogen and hydrogen fluoride Act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com