Nano-ceramic protective fluid and application thereof

A technology of nano-ceramics and protective fluid, applied in the field of nano-coatings, which can solve the problems of consuming large toilet cleaners, destroying the water environment, and polluting water bodies, achieving dimensional stability and natural appearance, excellent anti-aging performance, and avoiding long-term accumulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

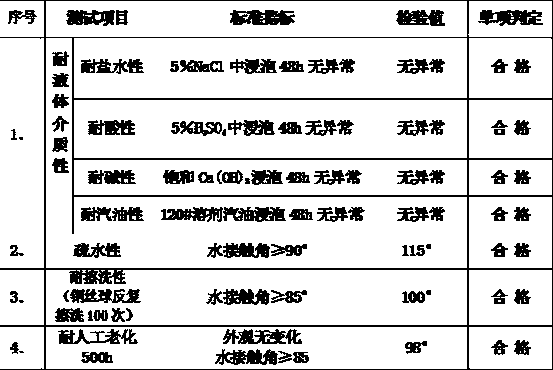

[0035] Mix BYK-110, 1 part; silicone surfactant, 3 parts; coupling agent DL171, 1 part; solvent D80, 70 parts; defoamer BYK-052, 0.2 parts; 5 parts; Stir and disperse for 60 minutes to obtain a uniform liquid (the above components are weight ratio components). Through the test, the main performance indicators of the ceramic protective fluid are as follows:

[0036]

Embodiment 2

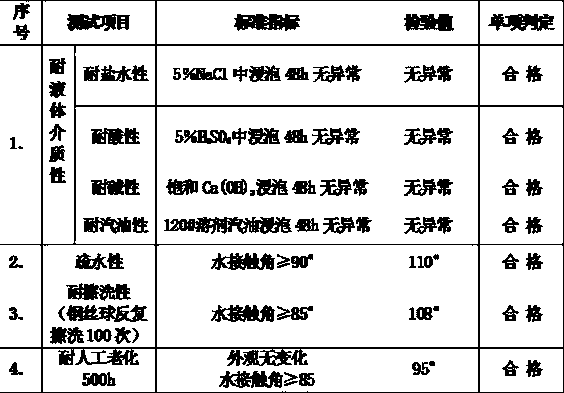

[0038] Put BYK-161, 4 parts; silicone surfactant, 10 parts; coupling agent KH560, 3 parts; solvent D40, 50 parts, butyl acetate, 15 parts; BYK-071, 1 part, after fully mixing and stirring , adding nano silicon dioxide, 3 parts, nano nano tin antimony oxide, 3 parts; after stirring and dispersing for 60 minutes, a uniform liquid was obtained (the above components are weight ratio components). Through the test, the main performance indicators of the ceramic protective fluid are as follows:

[0039]

Embodiment 3

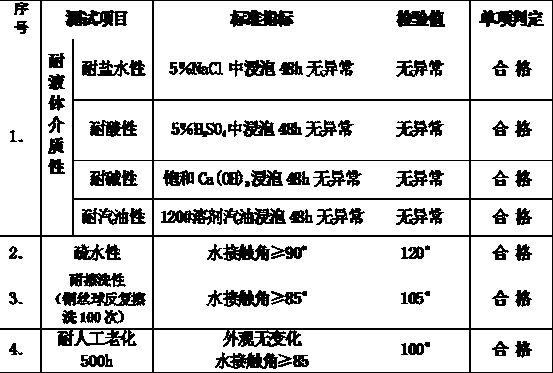

[0041] Mix BYK-103, 5 parts; fluorosurfactant, 5 parts; coupling agent DL602, 2 parts; D40, 40 parts, D80, 35 parts; BYK-052, 0.5 parts, mix well, add nano oxide 2 parts of aluminum, 3 parts of nano-zinc oxide, 3 parts of nano-indium tin oxide; after 60 minutes of stirring and dispersing, a uniform liquid is obtained (the above components are weight ratio components). Through the test, the main performance indicators of the ceramic protective fluid are as follows:

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com