Scale and corrosion inhibitor performance test dynamic simulation device and control method thereof

A scale and corrosion inhibitor and dynamic simulation technology, which is applied in the field of scale and corrosion inhibitor performance testing, can solve the problems of inability to adjust heating power, deviations in actual conditions, and differences in boiler operating conditions, so as to avoid a sharp increase in air pressure , avoid large fluctuations, and reduce the effect of waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

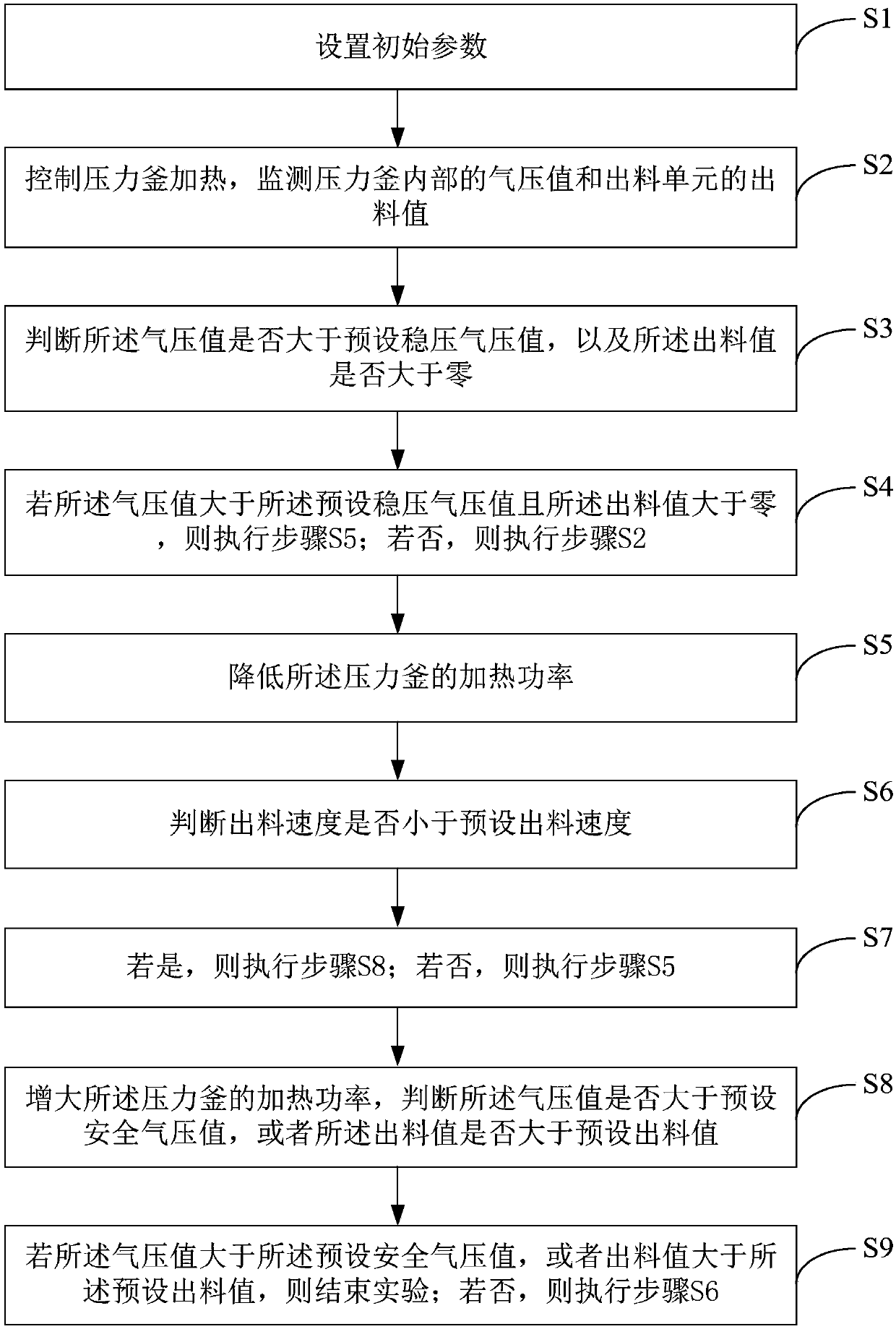

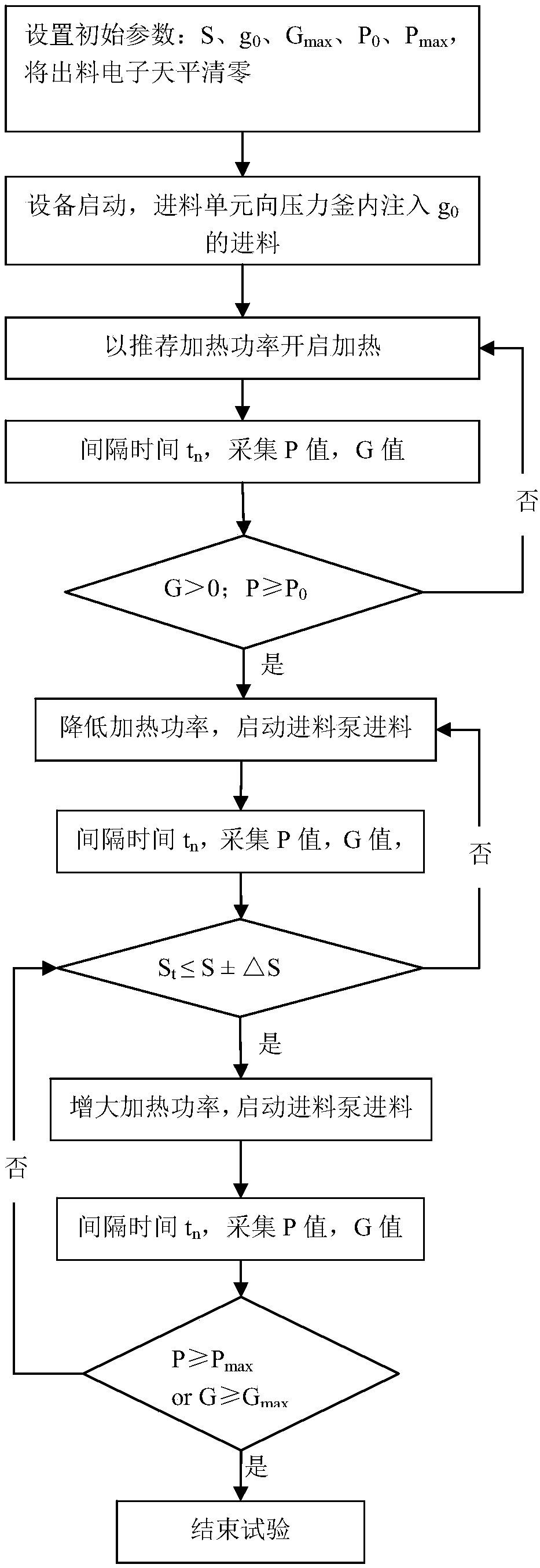

[0050] The invention discloses a dynamic simulation device for performance testing of scale and corrosion inhibitors. The dynamic simulation device simulates the heating, evaporation and concentration processes of boiler water, and automatically adjusts the heating power according to the discharge speed and heating temperature set by the operator. , The test process has good repeatability, and the material can be cooled quickly after the test or in an emergency, improving efficiency and safety.

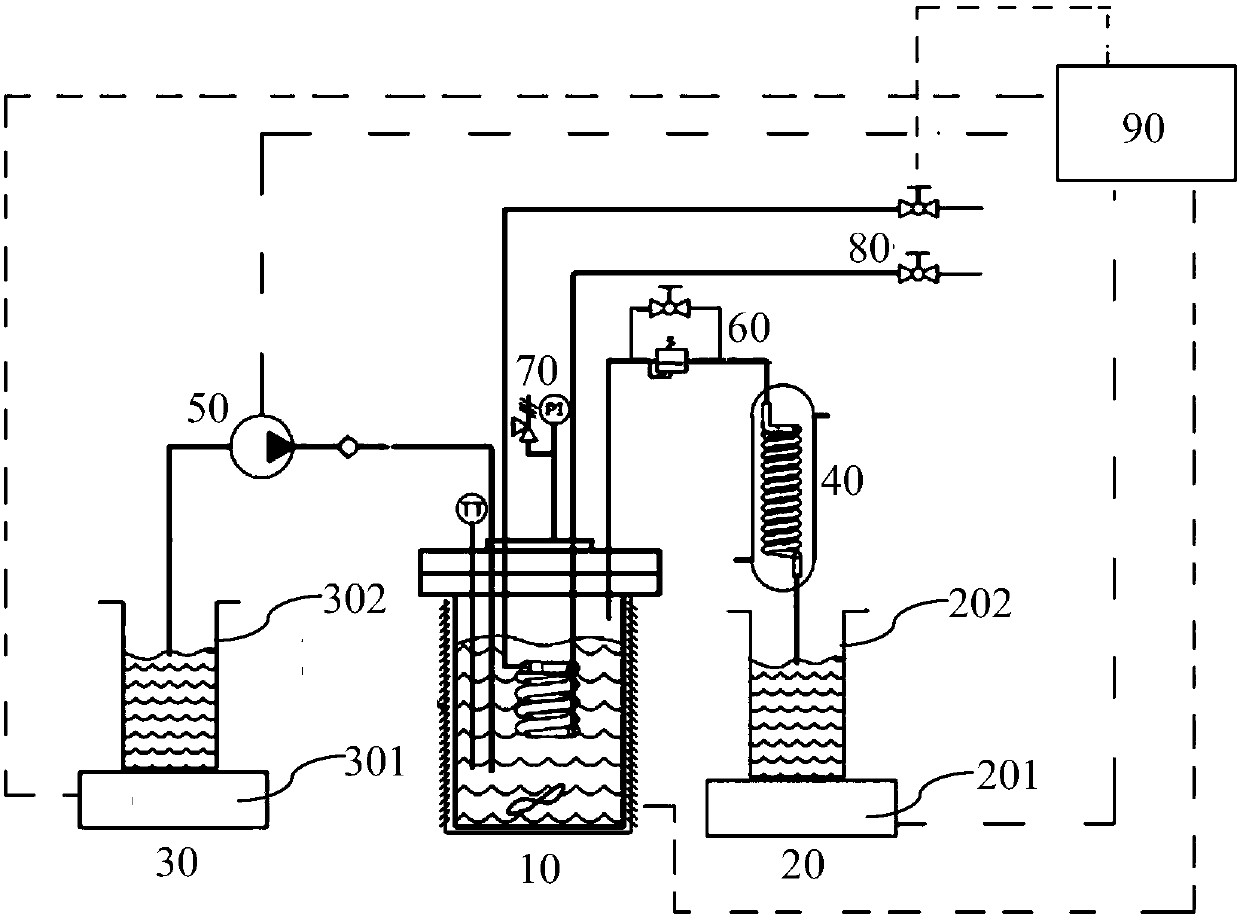

[0051] Such as figure 1 As shown, the dynamic simulation device for performance testing of scale and corrosion inhibitors of the present invention includes: a controller 90, an autoclave 10, a discharge unit 20, a feeding unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com