LED packaging structure

A technology of LED packaging and packaging structure, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of affecting heat dissipation effect, small heat capacity of metal heat dissipation substrate, and easy deformation, so as to increase heat dissipation effect, improve luminous dispersion, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

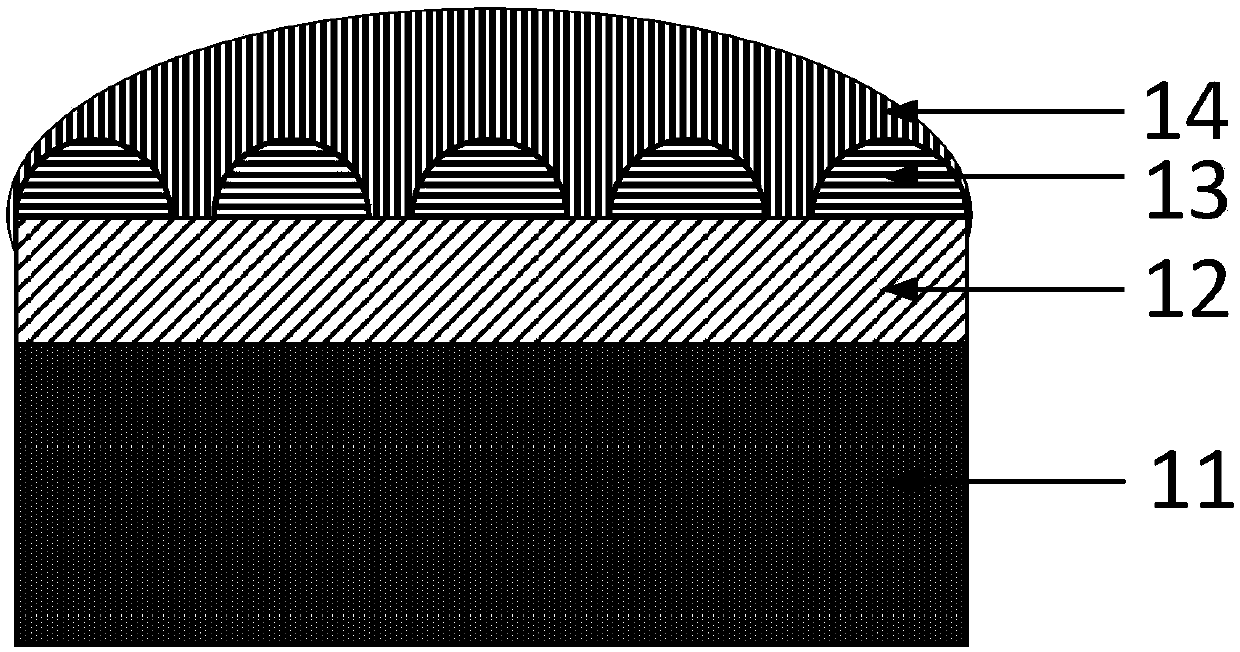

[0032] See figure 1 , figure 1 A schematic diagram of an LED package structure provided for an embodiment of the present invention, including: an LED base plate 11, a first silica gel layer 12, a hemispherical lens area 13, and a second silica gel layer 14; wherein, the first silica gel layer 12 is disposed on the On the LED bottom plate 11 , the hemispherical lens area 13 is disposed on the first silica gel layer 12 , and the second silica gel layer 14 is disposed on the first silica gel layer 12 and the lens area 13 .

[0033] Specifically, the refractive index of silica gel in the first silica gel layer 12 , the second silica gel layer 14 and the hemispherical lens area 13 increases sequentially.

[0034] Specifically, the LED bottom plate 11 includes a heat dissipation substrate and LED chips, wherein the LED chips are disposed on the heat dissipation substrate.

[0035] Preferably, the heat dissipation substrate is a copper material heat dissipation substrate.

[0036]...

Embodiment 2

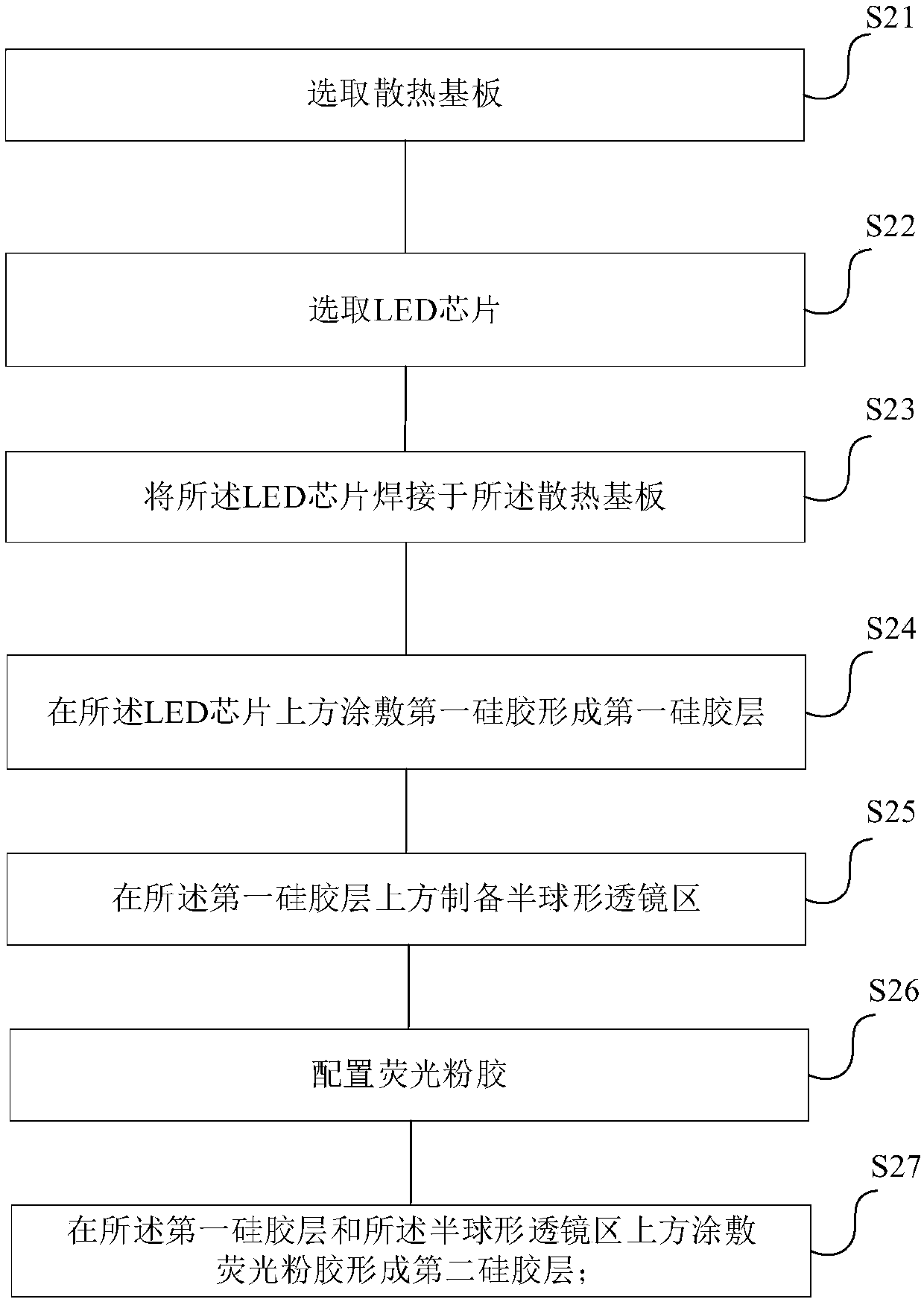

[0045] Please refer to image 3 , image 3 The flow chart of the LED packaging method provided by another embodiment of the present invention, this embodiment is based on the above-mentioned embodiments, and the packaging method of the LED packaging structure of the present invention is described in detail as follows. Specifically, include the following steps:

[0046] S21, selecting a heat dissipation substrate;

[0047] S22, selecting LED chips;

[0048] S23. Welding the LED chip to the heat dissipation substrate;

[0049] S24, coating the first silica gel on the LED chip to form a first silica gel layer;

[0050] S25. Prepare a hemispherical lens area above the first silica gel layer;

[0051] S26, configuring fluorescent powder glue;

[0052] S27. Apply phosphor glue on the first silica gel layer and the hemispherical lens region to form a second silica gel layer; to complete the LED package.

[0053] Specifically, step S21 may include:

[0054] S211, selecting a h...

Embodiment 3

[0088] Further, please refer to Figure 5 , Figure 5 It is a schematic diagram of a high-transmittance LED package structure provided in another embodiment of the present invention. The LED package structure provided in this embodiment is prepared by the method provided in the above-mentioned embodiments. Specifically, the LED packaging structure includes: a heat dissipation substrate 31 , an LED chip 32 , a first silicone layer 33 , a hemispherical lens area 34 and a second silicone layer 35 from bottom to top.

[0089] Specifically, the LED chip is an ultraviolet LED chip; please refer to Image 6 , Image 6 A schematic structural diagram of an ultraviolet LED chip provided in another embodiment of the present invention, the ultraviolet LED chip includes a sapphire substrate 301, an N-type AlGaN layer 302, an Al x Ga 1-x N / Al y Ga 1-y N multi-quantum well structure 303, P-type AlGaN barrier layer 304, P-type GaN layer 305; and, the positive electrode 306 disposed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com