Light cultivation method of rice by mechanized hill-direct-seeding

A cultivation method, the technology of direct seeding in holes, applied in the field of light cultivation of mechanical hole direct seeding rice, can solve the problems of low sowing mechanization, high loss, labor shortage, etc., avoid the influence of seed germination and rooting, improve fertilizer utilization efficiency and output and the effect of increasing the level of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

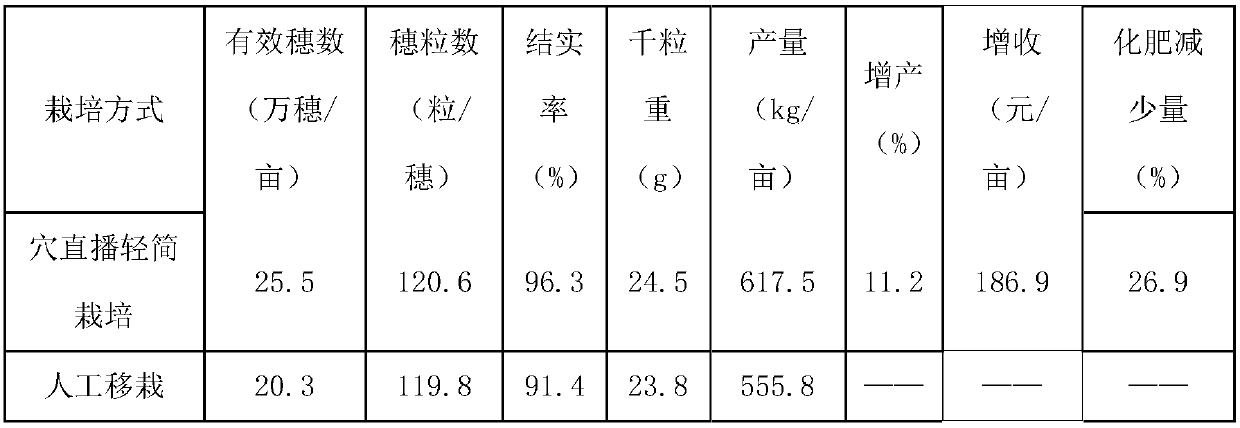

[0024] From June to October 2017, the light cultivation method of direct-seeding rice in mechanical holes was implemented in Zhonglong Town, Chaohu City, Anhui Province.

[0025] Wheat mechanized crushing and returning to the field: On May 15, the wheat was harvested with a wheat combine harvester, and the wheat straw was chopped to a length of 1-5cm by the straw cutting device attached to the harvester, and evenly sprinkled on the field surface;

[0026] Soil preparation: On May 18, the field surface was irrigated with 3-5cm of water to soak the field. The medium-sized tractor was equipped with a grass-burying rotary tiller to complete the grass-burying and site preparation at one time, and the burial depth of the wheat straw returning to the field was 5-10cm. The field surface is 10-15cm, and the field surface after site preparation is muddy or maintains an aquifer of 1-3cm, the field surface is flat, and the height difference is 0-3cm;

[0027] Rice seed selection and treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com