Zinc-rich efficient slow release special corn fertilizer and preparation method thereof

A technology of special fertilizer and elements for corn, which is applied in the field of slow and controlled release fertilizer, to achieve the effects of enhanced drought resistance, long fertilizer effect period and improved stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

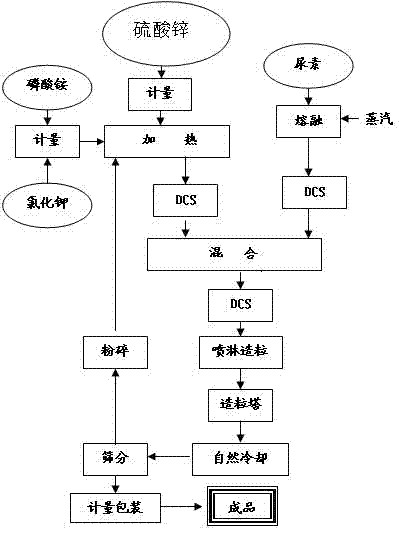

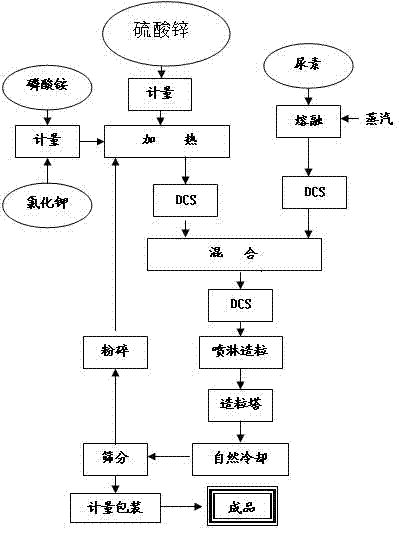

Image

Examples

Embodiment 1

[0070] Example 1: Prepare a special fertilizer for high-efficiency slow-release corn rich in zinc, wherein the contents of nitrogen, phosphorus pentoxide and potassium oxide are 28%, 6% and 6% respectively, which are percentages by mass.

[0071]Take 580kg of small granule urea, 140kg of monoammonium phosphate, 100kg of potassium chloride, 2kg of urease inhibitor, 10kg of zinc sulfate, and 168kg of bentonite as raw materials.

[0072] Accurately measure the above-mentioned raw materials, and use the tower melt granulation process for spray granulation production: use urea melt to mix with raw materials such as monoammonium phosphate and potassium chloride strictly measured according to the formula to form a low eutectic melt with good fluidity The solid suspension mixed slurry, and through the granulation nozzle, the mixed slurry is sprayed into the granulation tower, so that it exchanges heat with the rising air flow during the gravity fall process, cools and solidifies to for...

Embodiment 2

[0074] Example 2: Prepare a special fertilizer for high-efficiency slow-release corn rich in zinc, wherein the contents of nitrogen, phosphorus pentoxide, and potassium oxide are 30%, 5%, and 5% respectively, which are percentages by mass.

[0075] Get 630kg of small grain urea, 110kg of monoammonium phosphate, 100kg of potassium sulfate, 3kg of urease inhibitor, 8kg of medium and trace elements such as zinc sulfate, and 149kg of bentonite as raw materials; the preparation process is the same as in Example 1.

[0076] Comparative example: 54% ordinary potassium chloride compound fertilizer, the ratio of nitrogen, phosphorus and potassium is 18-18-18, and it is Sanan compound fertilizer produced by Stanley Fertilizer Co., Ltd.

[0077] The applicant set the test in Nangu Town, Linshu County, Shandong Province. The soil type is fluvo-aquic soil, and the soil nutrient content: organic matter 1.10%, available nitrogen 120ppm, available phosphorus 12.4ppm, and available potassium 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com