Method for treating waste gas in preparation process of composite fiber sealing material

A technology of sealing materials and composite fibers, which is applied in the field of pulp and paper making or the environment, can solve problems such as complex exhaust gas components, and achieve the effect of reducing the processing load and fully collecting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

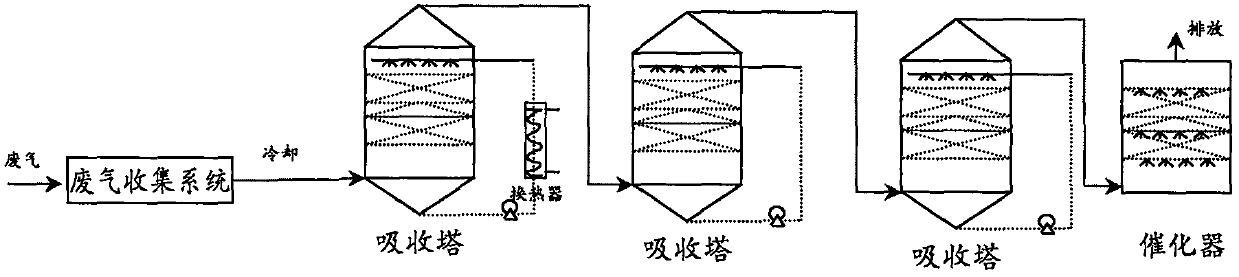

[0022] The waste gas during the preparation of composite fiber sealing materials is effectively treated by the following methods, and the by-products are reused:

[0023](1) Collection of waste gas: Since waste gas is generated during the entire curing process of composite fiber sealing materials, which is dispersed in the entire workshop, the waste gas must be effectively collected before processing the waste gas to avoid its arbitrary diffusion, which is generated by machines in the workshop. Add a closed system to the part of the exhaust gas, install the corresponding pipeline, and use the fan to extract the exhaust gas. The negative pressure at the top of the workshop is 90kPa; In the upper air, the wind pressure is 50kPa, so that a certain negative pressure is generated in the workshop to ensure that the exhaust gas in the workshop will not diffuse outward, and the exhaust gas can be fully collected;

[0024] (2) Pretreatment of exhaust gas: the initial temperature of exh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com