Non-contact continuous biological dealkalization technology for red mud

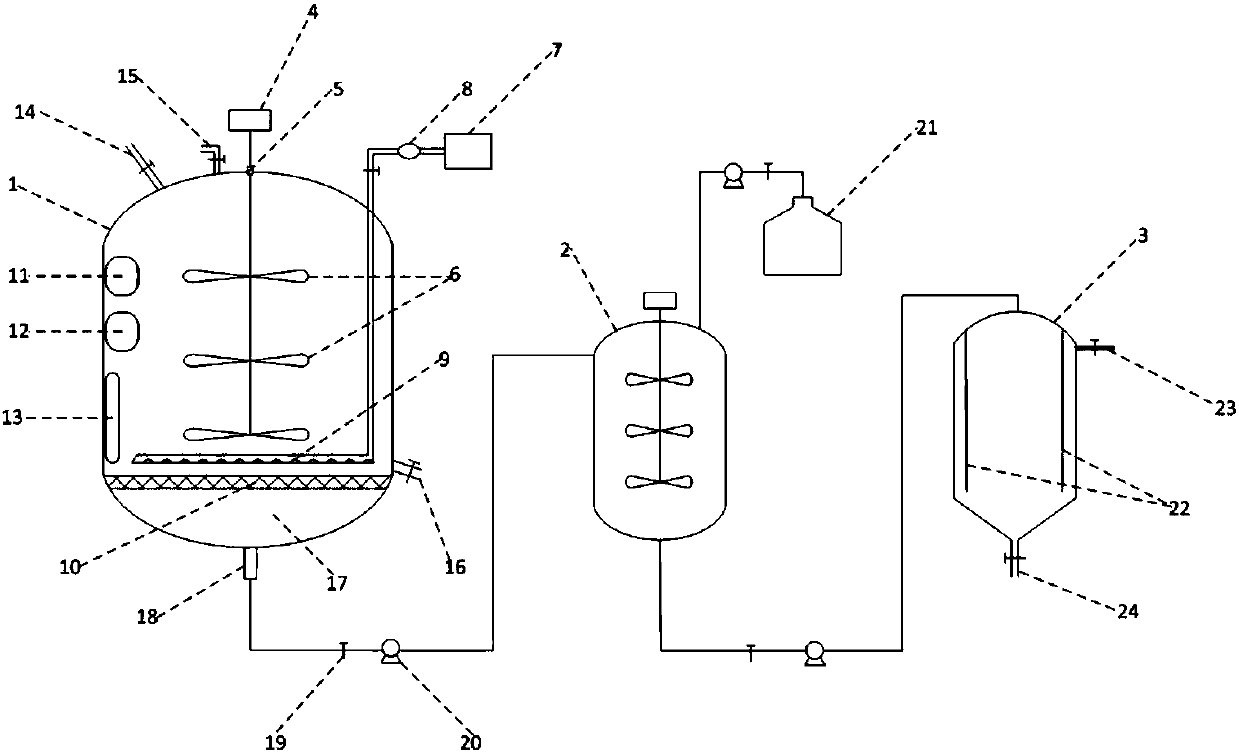

A non-contact, dealkalization technology, applied in the field of biological dealkalization system of red mud, can solve problems such as low dealkalization efficiency, and achieve the effects of avoiding adverse effects, strong metabolic acid production capacity, and short biological dealkalizing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] First sterilize 22L medium in a high-temperature sterilization pot at 121°C and 103kPa for 30min. The medium components are: 2.2kg sucrose, 3.3g yeast extract, 3.3g beef extract, KNO 3 6.6g, the solvent is deionized water. Inoculate 50 mL of Aspergillus niger spore suspension in the medium when the medium is cooled. Pump the inoculated medium into the acid-producing filter tank at one time. The effective volume of the acid-producing filter tank is 23L, and the material is stainless steel. membrane.

[0076] Turn on the stirring device, the aeration device and the temperature control device of the acid production filter tank, and adjust the operating parameters to: stirring speed 200rpm, temperature 33°C, dissolved oxygen 2.5mg / L. After the acid production filter tank has been in operation for 2 days, the start-up phase of the system is over, the growth and domestication of Aspergillus niger is completed, and the system enters the continuous acid production phase.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com