Patents

Literature

62results about How to "Direct discharge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fully recovering silicon dioxide in waste SCR (Selective Catalyst Reduction) catalyst

The invention relates to the field of smoke denitration, in particular to a method for fully recovering silicon dioxide in a waste SCR (Selective Catalyst Reduction) catalyst. The method comprises the following steps: soaking the pulverized waste SCR catalyst with three to four times of water to remove impurities, leaching powder from which the impurities are removed with excessive thick alkaline solution with the concentration of 60-80wt%, filtering to obtain a Na2TiO3 solid, adding sulfuric acid into filtrate, regulating pH to 11.5-12.5 at a temperature of 70-90 DEG C, leaving the mixture to stand for 0.5-1h, filtering, and discarding filter cakes; adding sulfuric acid into the filtrate until the pH is regulated to 9-10 to obtain the silicate filter cakes, heating and stirring the silicate filter cakes in mixed acid of dilute sulfuric acid and oxalic acid at a temperature of 40-60 DEG C for 1-2h, filtering, washing the filter cakes with deionized water, washing off acid radical ions in the solid, and obtaining high-purity silicon dioxide through heating and decomposition. Therefore, the recovery of the silicon dioxide in the waste SCR catalyst can be realized without a roasting process.

Owner:沈阳远大固废处理有限公司

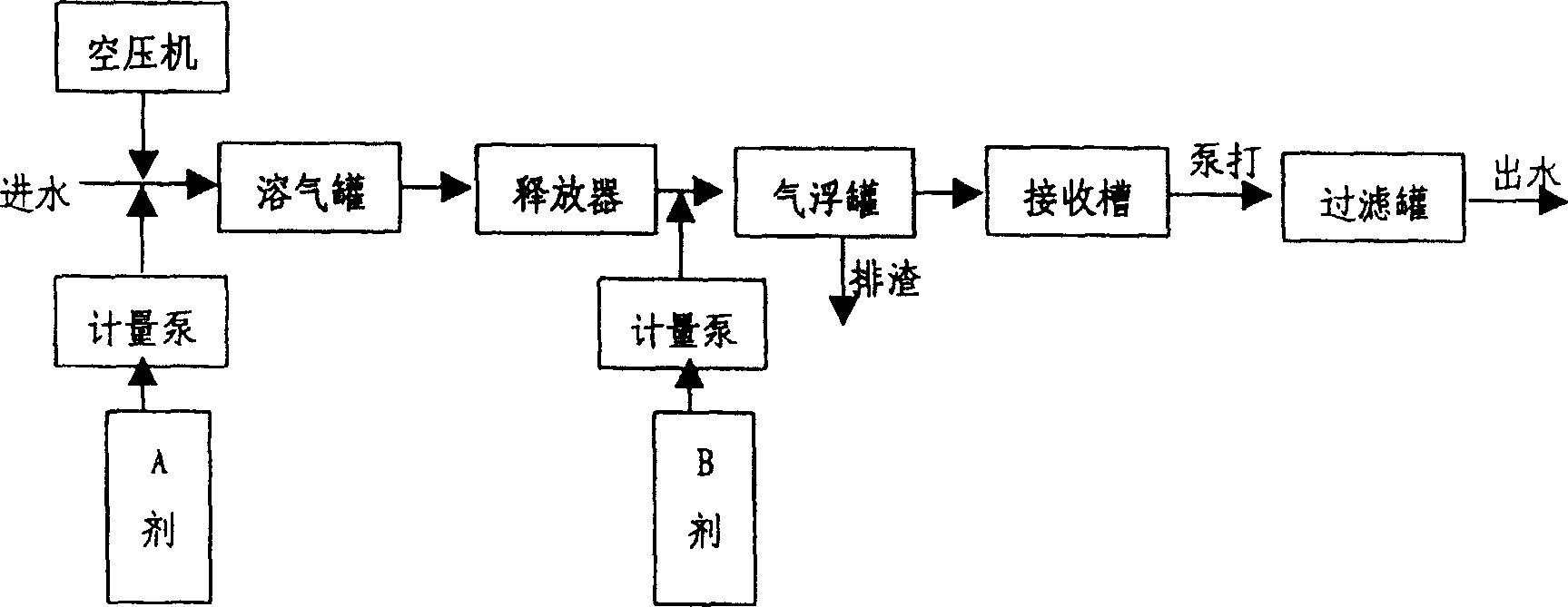

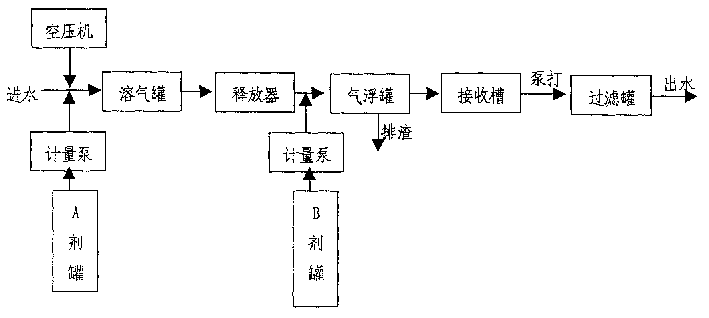

Method for treating naphthenic acid sewage by flocculation-electricity heterogeneous catalysis

InactiveCN1209302CEasy to handleTo achieve the purpose of preprocessingMultistage water/sewage treatmentSquare decimeterCatalytic oxidation

A flocculation-electroheterogeneous catalysis method for treating naphthenic acid wastewater. First, air flotation-flocculation treatment is carried out on naphthenic acid wastewater, the pressure is 0.2-0.4MPa, and the dosage of the agent is 0.01-0.07% of the wastewater volume; after the flocculation treatment, the DC voltage between the electrodes in the electric field is 5-15V, and the current Under an external electric field of 200-400 mA per square decimeter, the organic pollutants in the naphthenic acid wastewater are catalyzed and oxidized on the surface of the catalyst. The experimental results show that the combined technology can be used to treat naphthenic acid wastewater, which can be directly discharged up to the standard, and the operating cost is low.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

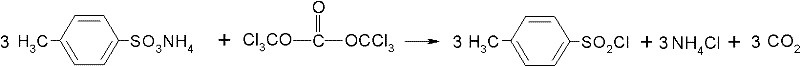

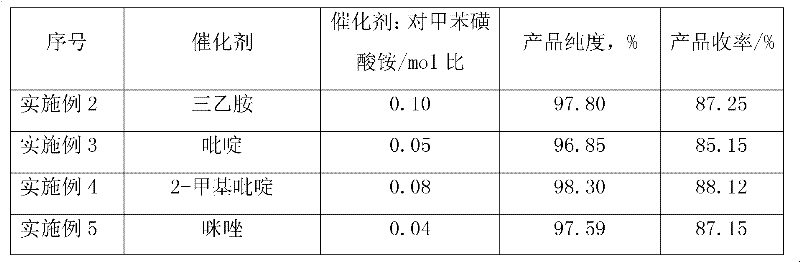

Method for preparing paratoluensulfonyl chloride

The invention discloses a method for preparing paratoluensulfonyl chloride, which comprises the following step of: reacting paratoluenesulfonic acid ammonium salt with bis(trichloromethyl) carbonate (commonly called triphosgene) in an inert organic solvent under the condition that organic alkali is used as a catalyst to synthesize the paratoluensulfonyl chloride. The preparation method has the advantages that: raw materials are conveniently and readily available, the process is simple and suitable for scale-up production, reaction conditions are mild, and a product is easy to purify. The prepared paratoluensulfonyl chloride is an important fine chemical product and can be used for preparing a dye intermediate, synthesizing intermediates of more than ten kinds of antibacterial medicines and anti-inflammatory medicines such as betamethasone, sulfamylon and the like and synthesizing plastic plasticizers, resin, coatings, pesticides and light-sensitive materials.

Owner:SINOCHEM LANTIAN +1

Plastic beverage bottle recycling device

The invention provides a plastic beverage bottle recycling device. The plastic beverage bottle recycling device comprises a cylinder fixedly arranged on a foundation and used for providing installing space, a horizontally-arranged extrusion plate movably arranged at the middle portion of the cylinder and used for dividing the cylinder into an upper extrusion space and a lower recycling space, an overturning cover movably arranged at the upper end portion of the cylinder, and an extrusion mechanism movably arranged on the overturning cover, the extrusion mechanism and the extrusion plate jointly apply force to extrude a plastic beverage bottle located in the upper extrusion space, and after the extrusion plate is moved after extrusion, the extruded plastic beverage bottle falls into the lower recycling space. The provided plastic beverage bottle recycling device has the beneficial effects of being easy to operate and easy to use and popularize.

Owner:SHAOYANG UNIV

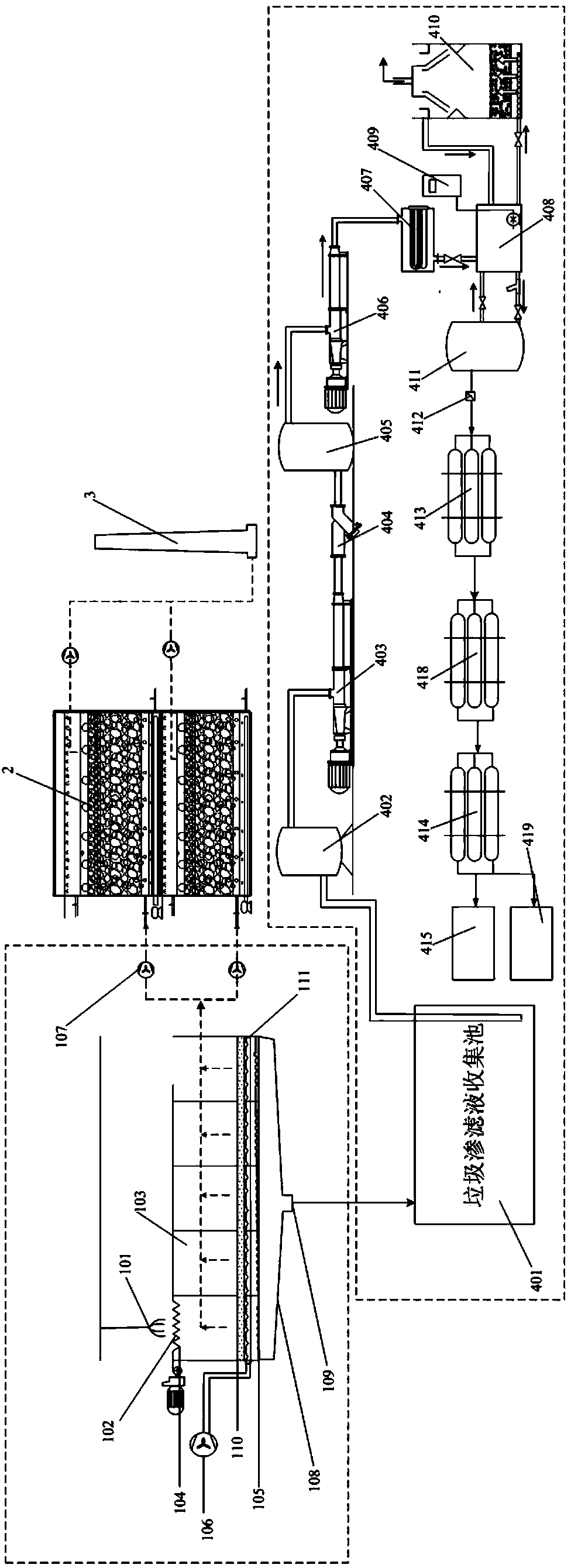

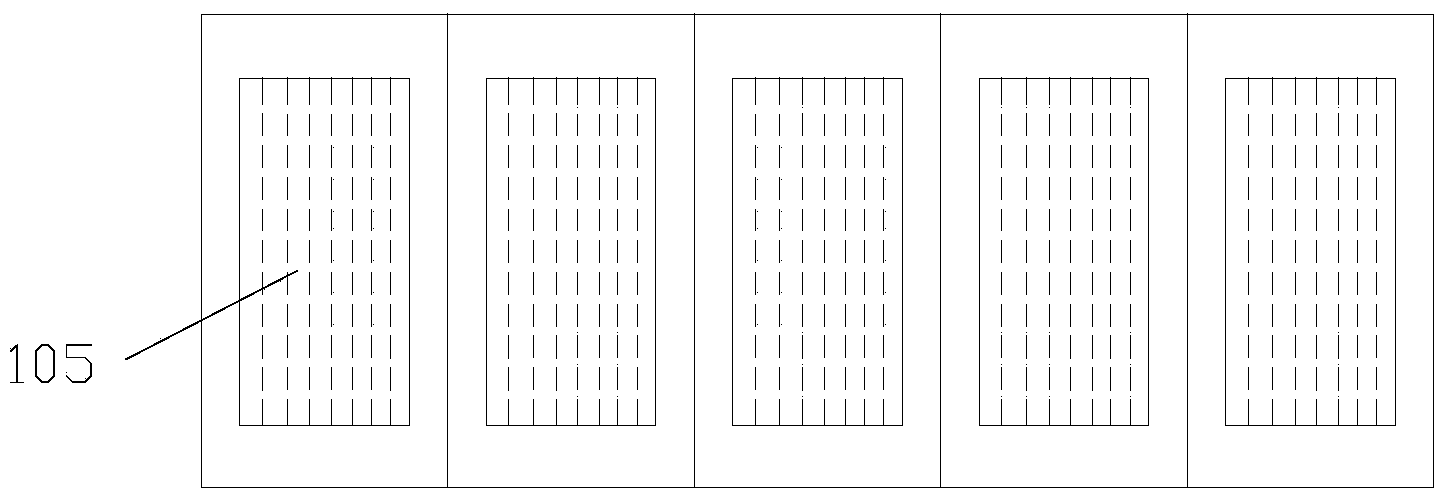

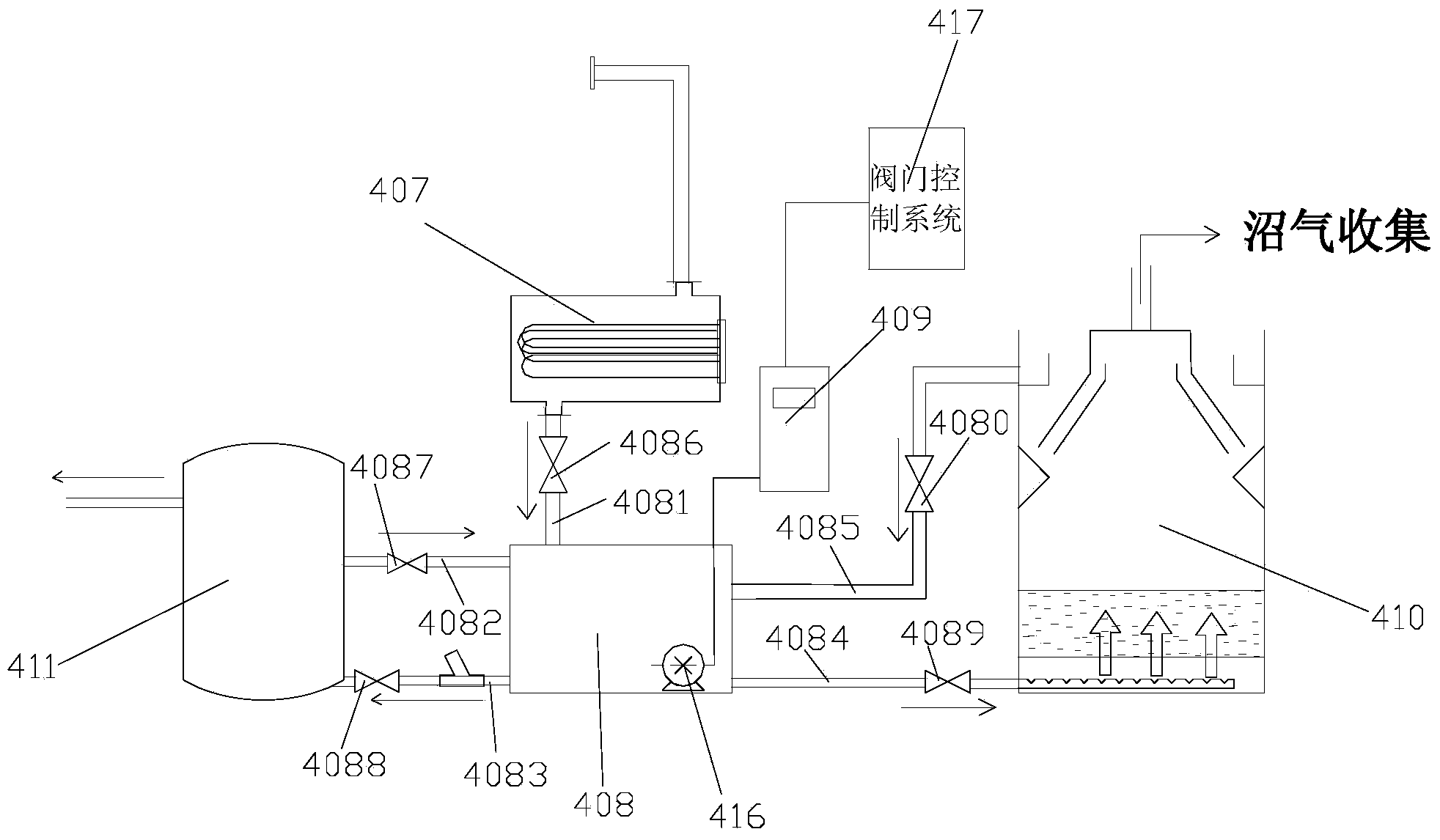

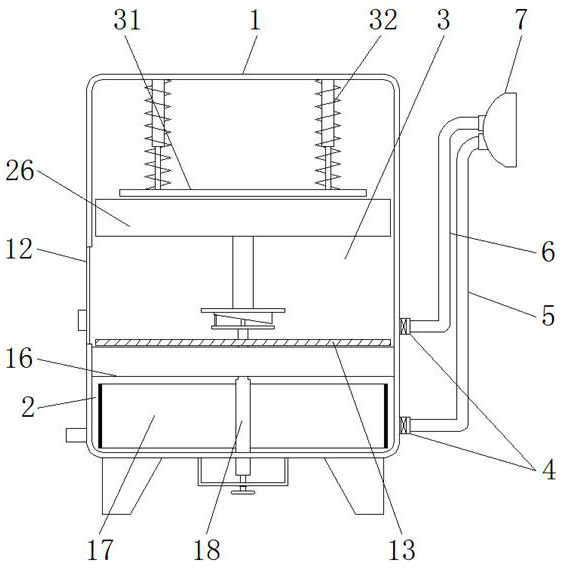

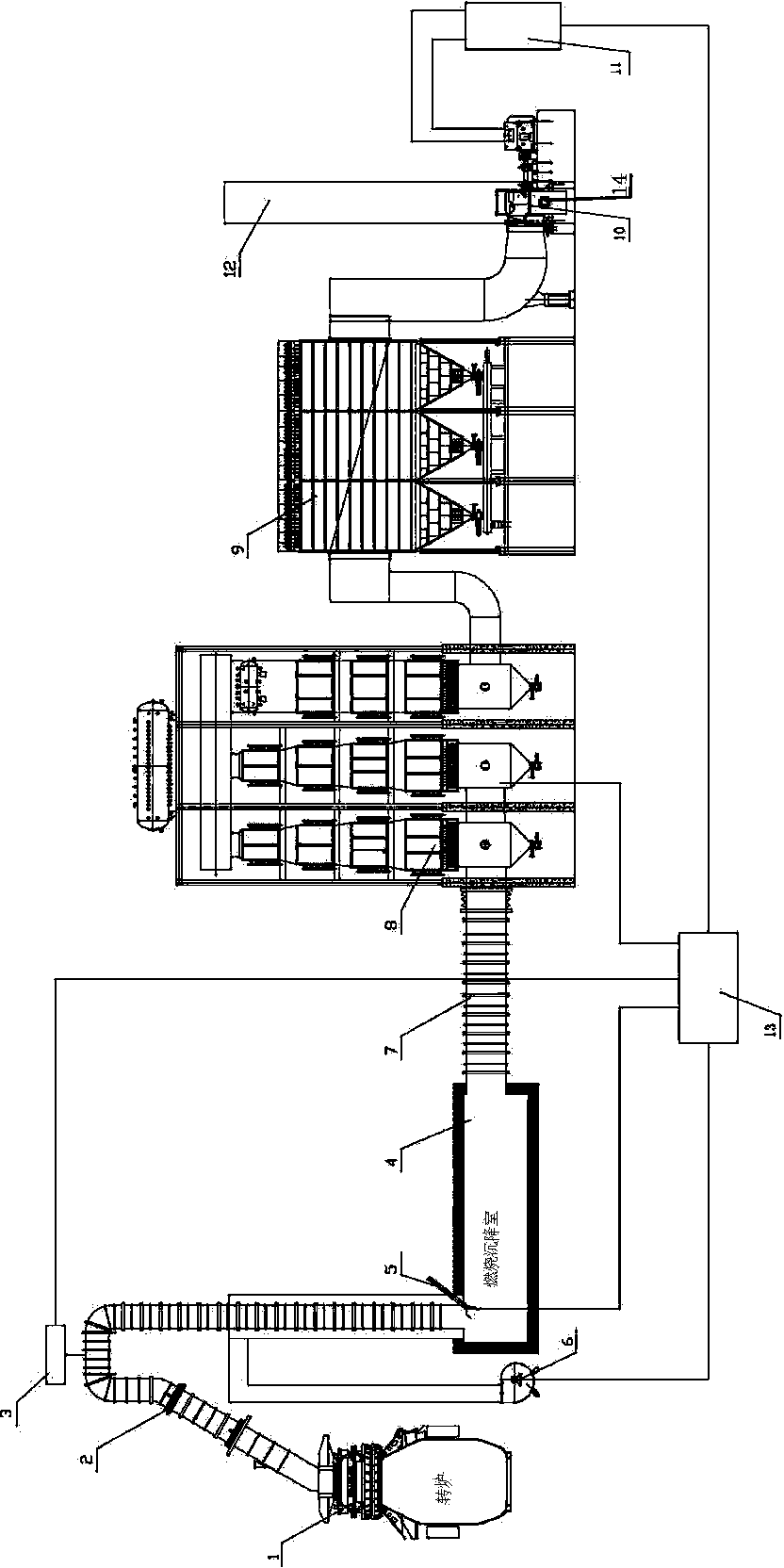

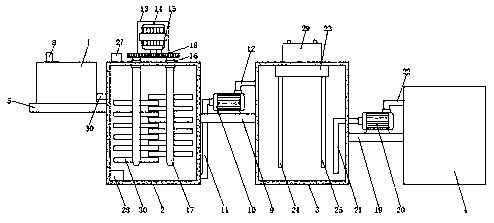

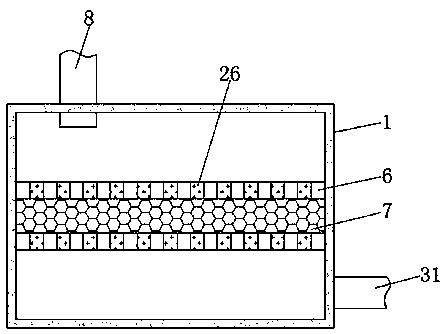

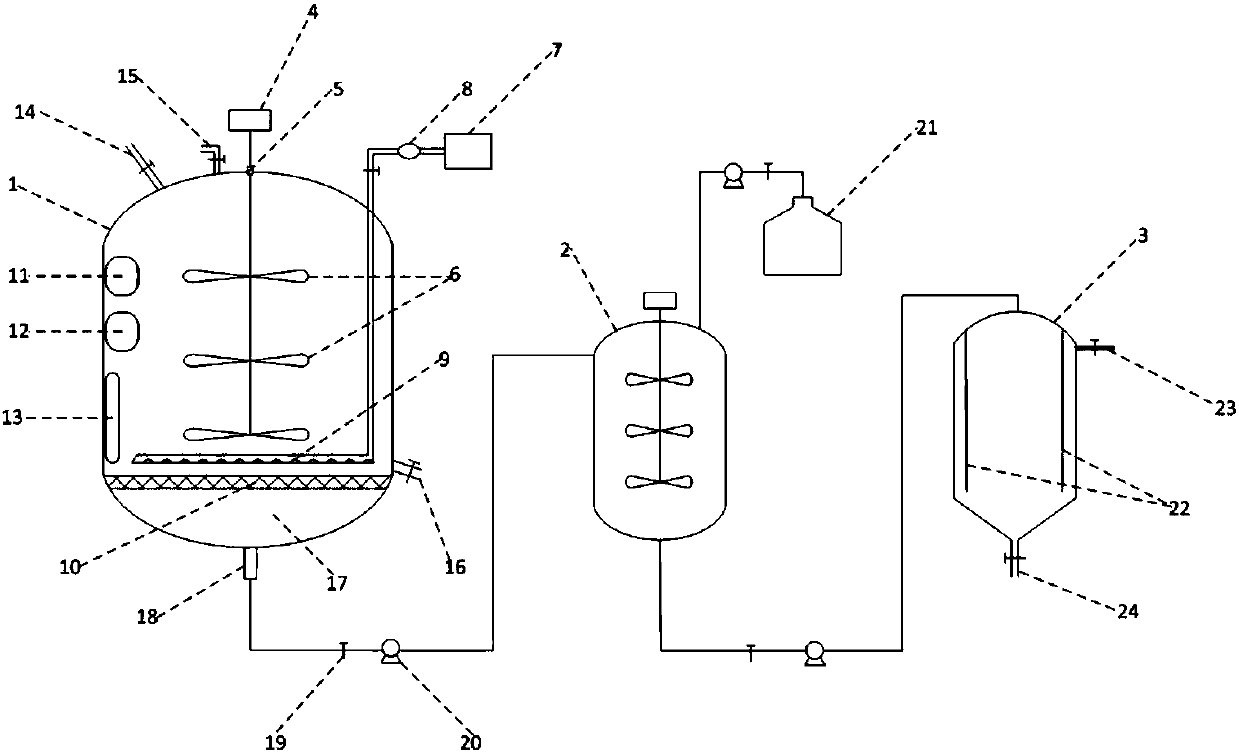

Garbage-drying and deodorization and percolate-disposing system and method

ActiveCN104275343AImprove drying efficiencyAvoid accumulationSolid waste disposalDispersed particle separationUltrafiltrationLitter

The invention relates to a garbage-drying and deodorizing and percolate-disposing system and method. The garbage-drying and deodorization and percolate-disposing system comprises a garbage-drying device, a deodorizing device and a percolate-disposing device, wherein the garbage-drying device comprises a garbage-drying region, a movable cover plate is arranged above the garbage-drying region and connected with a motor, a grabbing jaw is arranged above the movable cover plate, a ventilation isolation layer, a ventilation air pipe and a grid plate are arranged at the bottom of the garbage-drying region; and the percolate-disposing device comprises a percolate water-collecting basin, a pretreating basin, a heater, an anaerobic reactor, a nitrification / denitrification device, an ultrafiltration membrane device, a nanofiltration membrane device and a reverse osmosis membrane device. The method comprises the following steps: S1, drying garbage; S2, biologically deodorizing; S3, lifting and conveying percolate; and S4, disposing the percolate. According to the garbage-drying and deodorizing and percolate-disposing system and method, multiple links of disposing the garbage are improved, and thus garbage drying and percolate disposing efficiencies are improved, and the effect of biologically removing bad smell and microorganisms from the garbage is improved. The disposed tail gas and percolate can be emitted when reaching the standard.

Owner:HUAXIN CEMENT +2

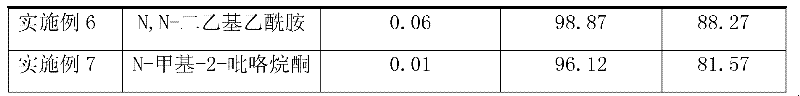

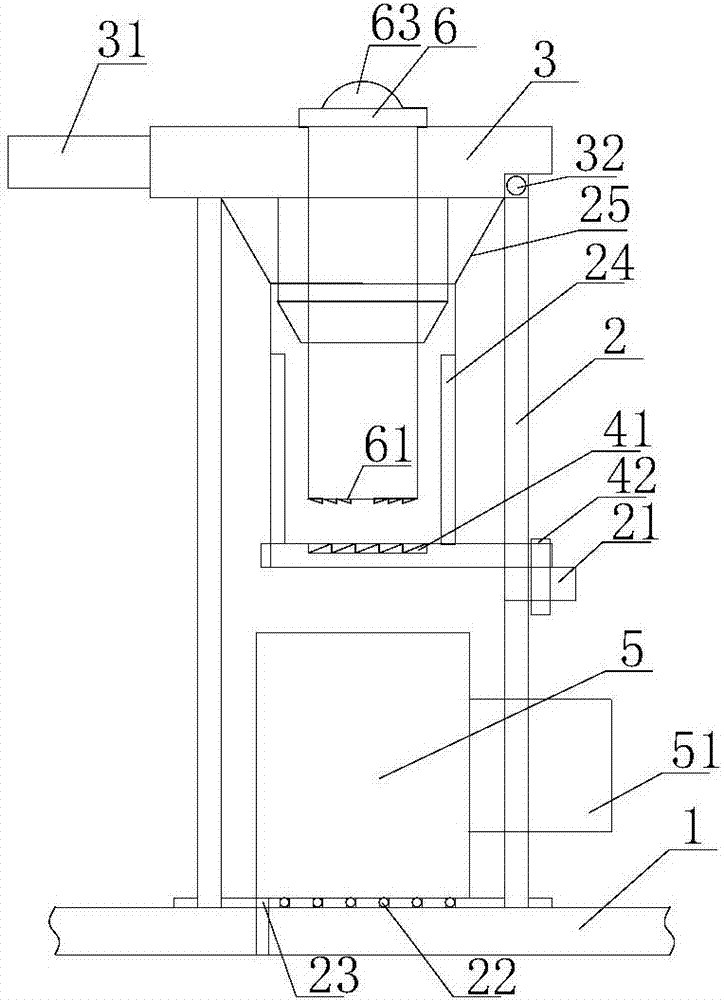

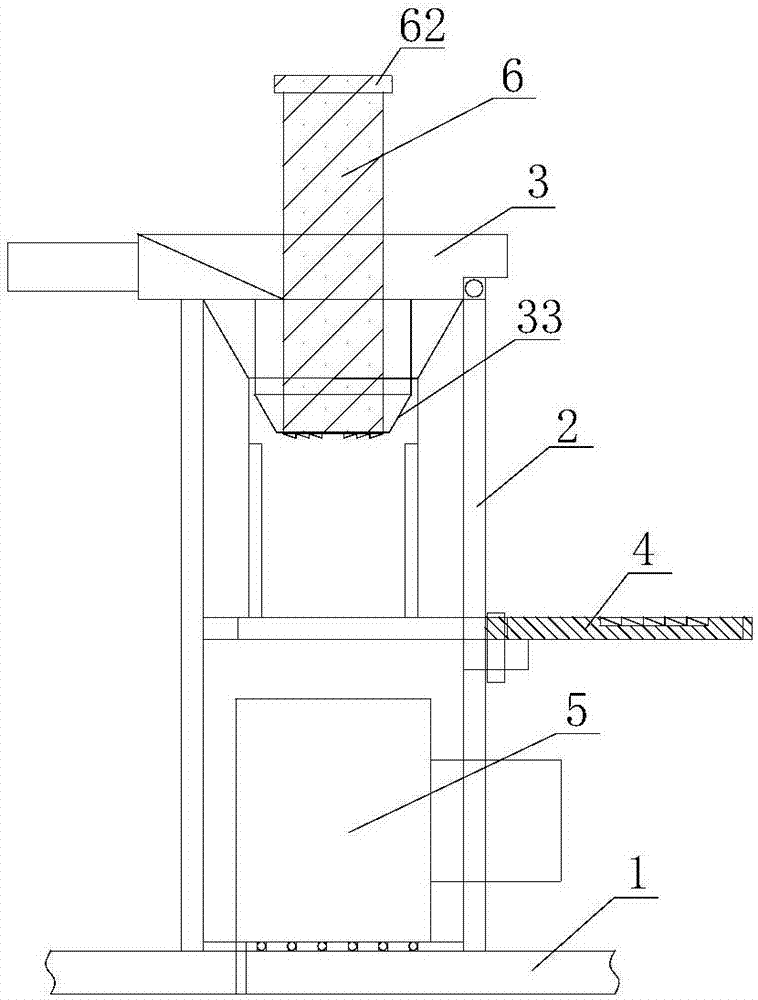

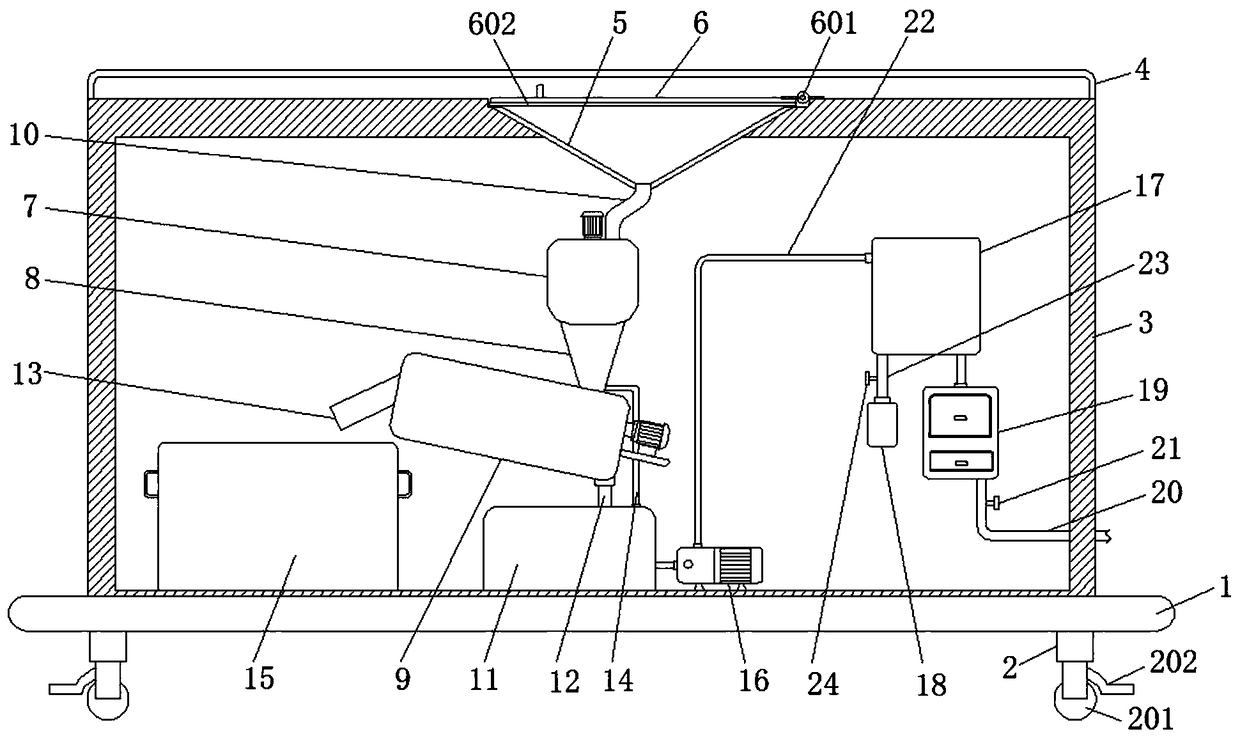

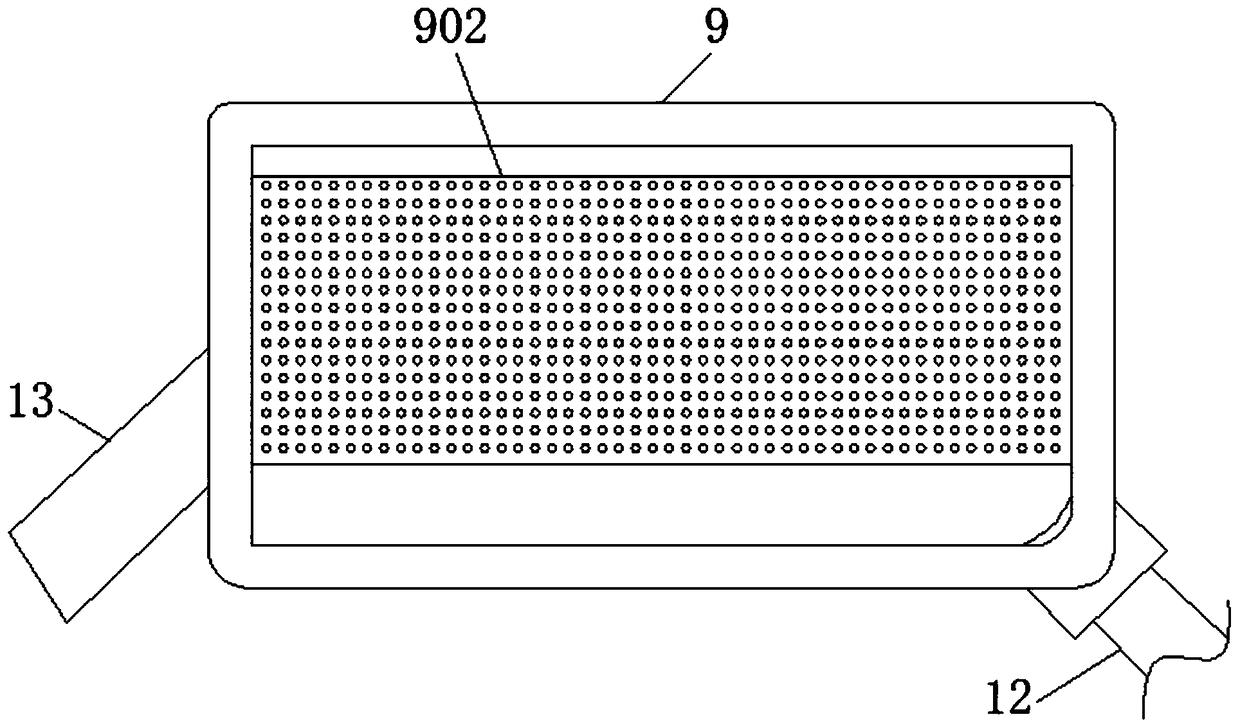

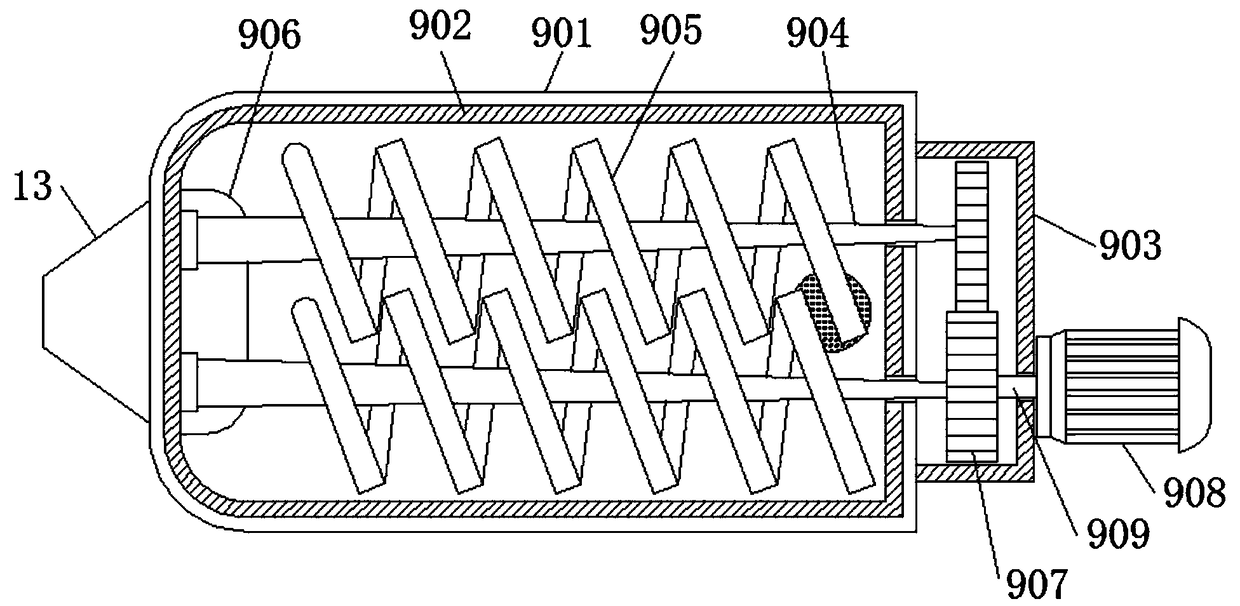

Portable environment-friendly kitchen waste disposal equipment

ActiveCN108817034ANo pollutionSave resourcesFatty/oily/floating substances removal devicesTransportation and packagingEngineeringRefuse Disposals

The invention discloses portable environment-friendly kitchen waste disposal equipment which comprises a base. Moving mechanisms are arranged at the four corners of the bottom of the base. A box bodyis fixedly mounted at the top of the base. The four sides of the top of the box body are fixedly connected with protection plates. A guide trough is arranged in the middle of the top of the box body.A sealing cover is arranged at the top of the guide trough. A crushing mechanism is arranged below the guide trough. A dewatering mechanism is fixedly connected to the bottom of the crushing mechanism. Through the arrangement of the guide trough, the crushing mechanism, the dewatering mechanism, a spiral extrusion mechanism, an oil-water collection box, a recovery barrel, a water pump, an oil-water separator, a waste oil collection bottle and a filter mechanism, kitchen waste can be subjected to solid-liquid separation and filter disinfection, solid kitchen waste can be crushed, filtered and separated, the separated solid kitchen waste can be recycled again, resources can be saved, and the aim of environment protection is achieved.

Owner:武汉明源碧景环保科技有限公司

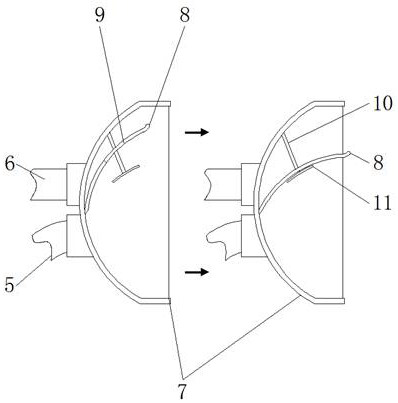

Lung function rehabilitation training device for respiratory medicine department

ActiveCN112843627AEnsure the effect of rehabilitation trainingAvoid condensationMedical devicesTherapy exerciseNoseInhaled air

The invention discloses a lung function rehabilitation training device fora respiratory medicine department. The device comprises a shell, an expiration cavity, an inspiration cavity, an air hole, an expiration pipe, an inspiration pipe and a mask, the expiration cavity and the inspiration cavity are formed in the shell, a turnover door installed on the shell is arranged on the left side of the inspiration cavity, a sponge pad is arranged in the inspiration cavity, and the sponge cushion is laid on the upper end face of the baffle. According to the lung function rehabilitation training device for a respiratory medicine department, a double-pipeline training structure is also adopted in the device, the internal structure of the mask can be adjusted according to the actual requirements of a patient, the purpose of rehabilitation training can be well achieved no matter whether the patient uses the mouth and the nose or purely breathes in the oral cavity, the mask does not need to be repeatedly removed, moreover, the interior of the device can be heated, a large number of water drops are prevented from being condensed in the device during expiration, inhaled air can be heated, humidified and dosed, and the effect of lung function rehabilitation training is guaranteed.

Owner:许云霞

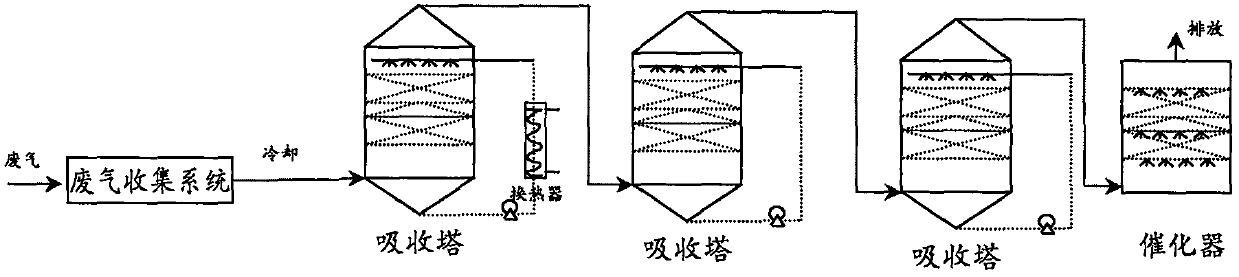

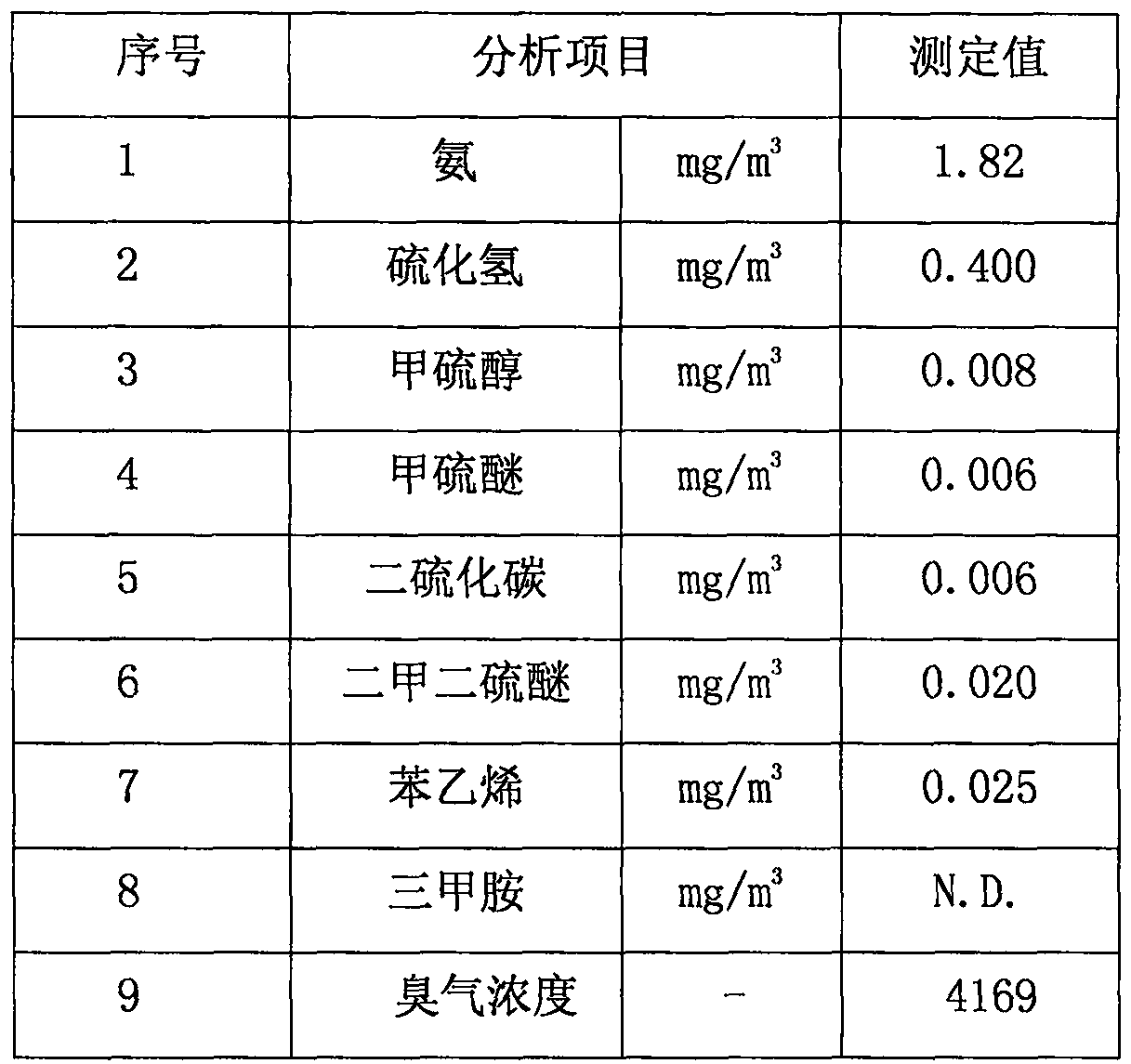

Method for treating waste gas in preparation process of composite fiber sealing material

ActiveCN107824033ADirect dischargeLower activation energyUsing liquid separation agentIncinerator apparatusFiberCatalytic oxidation

The invention relates to a method for treating a waste gas in a preparation process of a composite fiber sealing material, and belongs to the field of pulping and papermaking or environments. The method specifically comprises the following steps: collecting, cooling, classifying and absorbing, and catalytically oxidizing the waste gas in the production process of the composite sealing material toachieve effective control and standard treatment of the waste gas. The method provided by the invention has the advantages that the waste gas is classified and treated step by step in the preparationprocess of the composite fiber sealing material to achieve the purification of the waste gas; meanwhile, by-products generated in the purification process can be reused in the preparation process of the composite fiber sealing material without secondary waste generation.

Owner:中轻(晋江)卫生用品研究有限公司

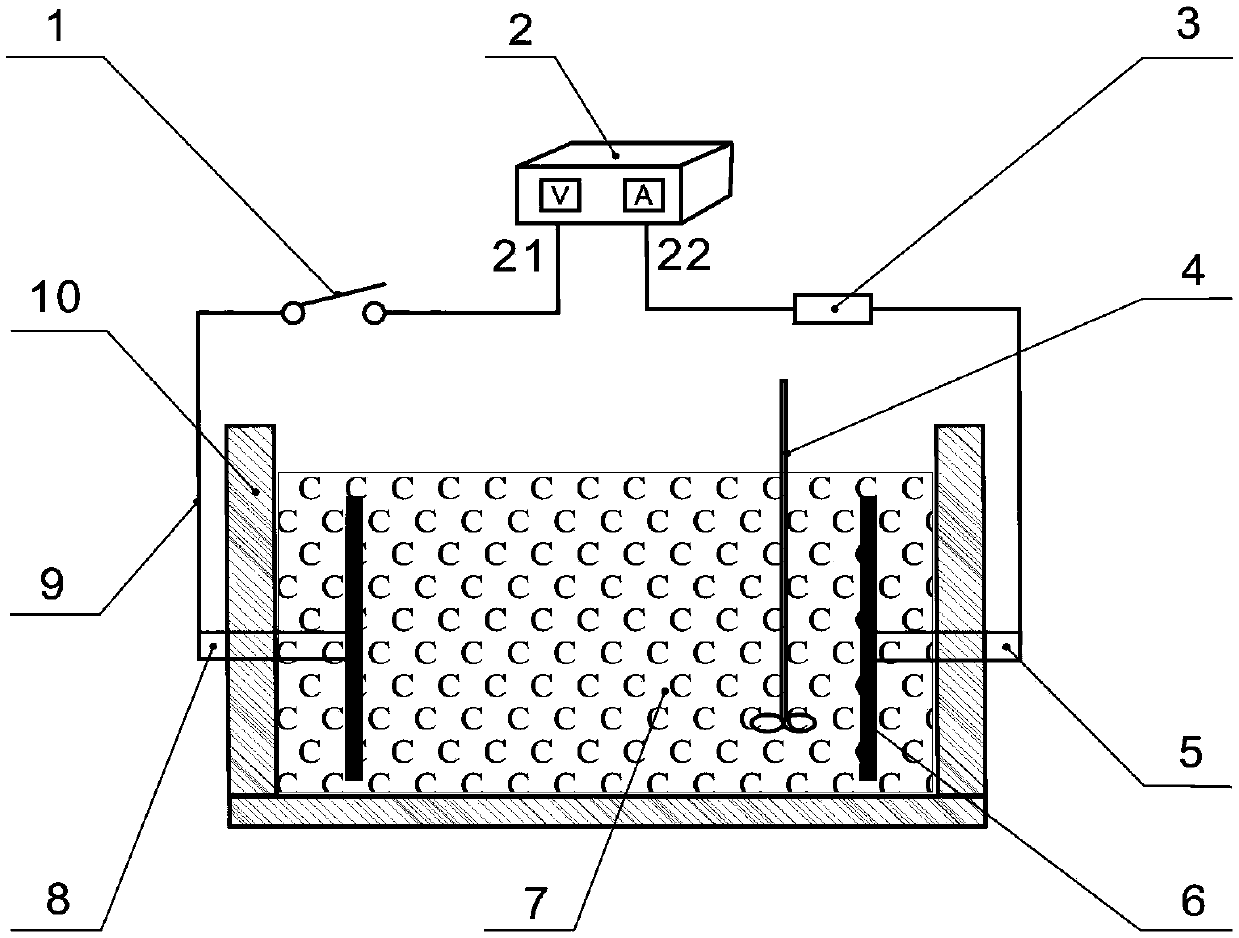

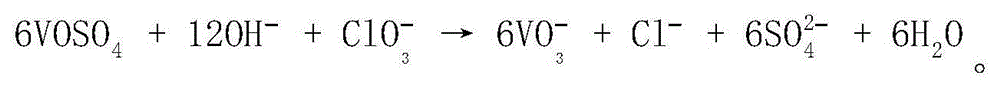

Method for catalytic oxidation treatment of anisole waste water

InactiveCN1569679ATo achieve the purpose of preprocessingDirect dischargeWater/sewage treatment using germicide/oligodynamic-processMetal/metal-oxides/metal-hydroxide catalystsChlorine dioxideCatalytic oxidation

The invention discloses a method for catalytic oxidation treatment of anisole waste water which consists of, first subjecting the methyl phenyl ether to chlorine dioxide catalytic oxidation treatment, at the presence of catalyst, treating 10-10 minutes to remove most of the organics, after chlorine dioxide catalytic oxidation treatment, proceeding electric-polyphase catalytic oxidation treatment at the presence of catalyst, applying external electric field to trigger catalyzed oxidation for the organic contaminant in the methyl phenyl ether waste water on the catalyst surface.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Direct-fired heat energy recovering and purifying system and technology of converter gas

ActiveCN103627844AEliminate water consumptionAvoid secondary pollutionManufacturing convertersIncreasing energy efficiencyDirect combustionFlue gas

The invention relates to a direct-fired heat energy recovering and purifying system and technology of converter gas. The adopted technical scheme is that a water-cooled flue gas recovery vessel hood is connected with a primary vaporizing and cooling flue; a CO / O2 analyzer is arranged on the primary vaporizing and cooling flue; the outlet of the primary vaporizing and cooling flue is connected with a burning settling chamber; an ignition device is arranged on the burning settling chamber; the burning settling chamber is connected with a combustion-supporting air supply device; the outlet of the burning settling chamber is connected with a secondary vaporizing and cooling flue; the outlet of the secondary vaporizing and cooling flue is connected with an afterheat boiler; the outlet of the afterheat boiler is connected with a bag-type dust remover; the outlet of the bag-type dust remover is connected with an induced draft fan and a motor; the induced draft fan and the motor adjust the revolution through a transducer; the outlet of the induced draft fan is connected with a chimney. By adopting the direct-fired heat energy recovering and purifying system and technology, heat energy released by CO in the converter gas in a direct burning manner and the heat energy in the flue gas can be recovered, and the flue gas after heat energy recovery is purified; the system is simple in equipment, high in safety performance, and good in dust removal effect.

Owner:HUANYU PURIFYING ENG EQUIP MFG DASHIQIAO CITY

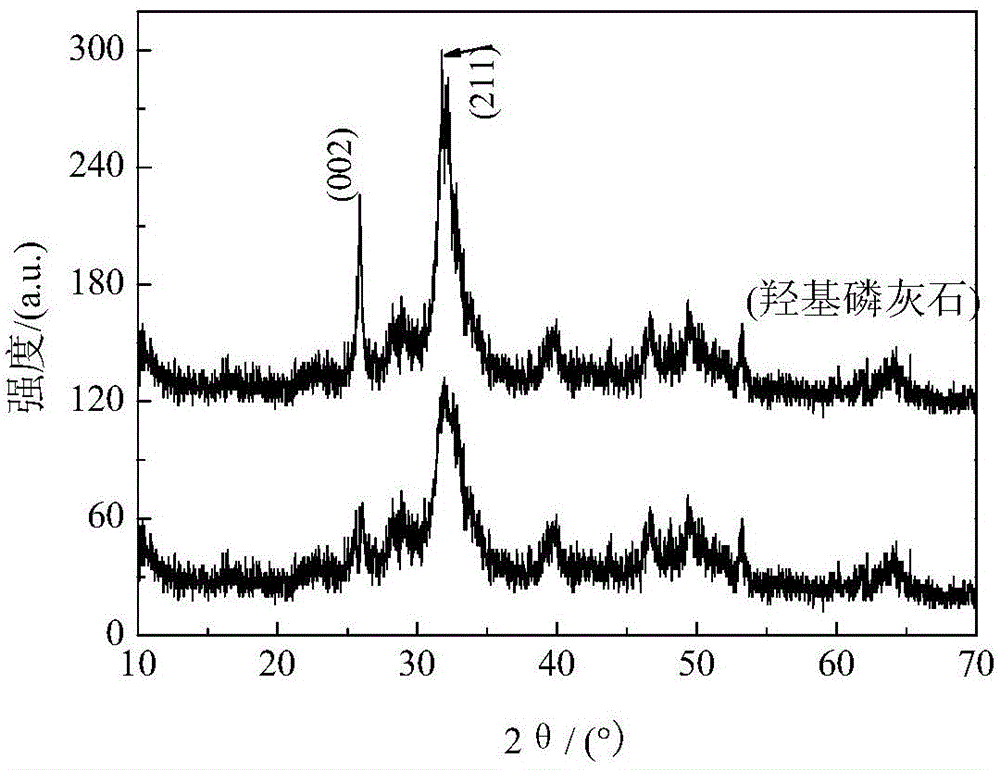

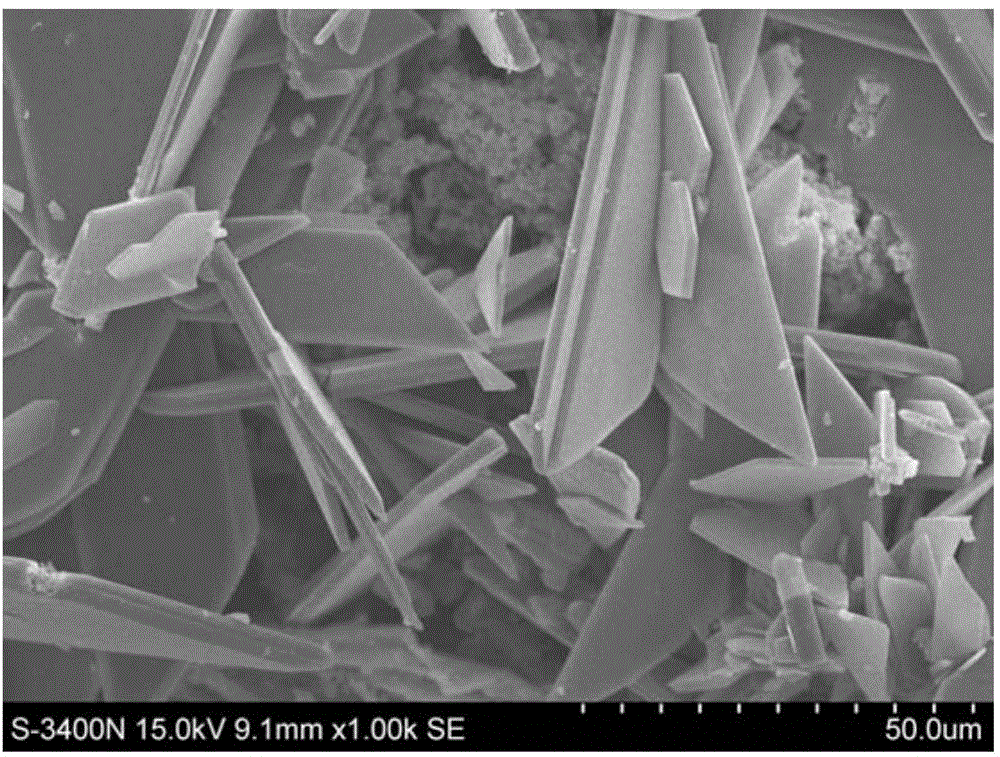

Method for recovering phosphorus from fosfomycin-containing wastewater

ActiveCN104591336APromote rapid formationEfficient degradationWater/sewage treatment by irradiationWater contaminantsFertilizerTobermorite

The embodiment of the invention discloses a method for recovering phosphorus from fosfomycin-containing wastewater. The method comprises the following steps: using a method of cooperating photoelectro-catalytic oxidation with hydroxyl calcium phosphate deposition; connecting a graphite anode and a stainless steel cathode into a photoelectro-catalytic reaction device, and taking an ultraviolet lamp as a light source, and an aqueous solution of NaCl as an electrolyte; and enabling the fosfomycin-containing wastewater to enter the reaction device while stirring, and pouring porous tobermorite into the reaction device, controlling a reaction voltage, temperature and time, monitoring water quality indexes in real time, and collecting a phosphorus recovery product after the reaction is finished. The process of recovering phosphorus disclosed by the invention is low in energy consumption and free from secondary pollution; moreover, the product after phosphorus recovery, namely hydroxyl calcium phosphate, can be used as a phosphatic fertilizer or a phosphorus-containing mineral for being used, thus realizing effective recovery for phosphorus resources while treating a polluted water quality.

Owner:CHONGQING UNIV OF ARTS & SCI

Solidifying device and method of natural latex

The invention provides a solidifying device and method of natural latex, and belongs to the field of natural rubber preparation. By arranging electrodes connected with a direct current generating device in an insulating container, the direct current electric field effect needed by natural latex solidification is generated between the electrodes, through the direct current electric field effect, the electric potential balance of protein isoelectric points on the surfaces of rubber particles in the natural latex is broken through, thus protective layers on the surfaces of the rubber particles lose the protecting effect, and the rubber particles are gathered and finally solidified.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

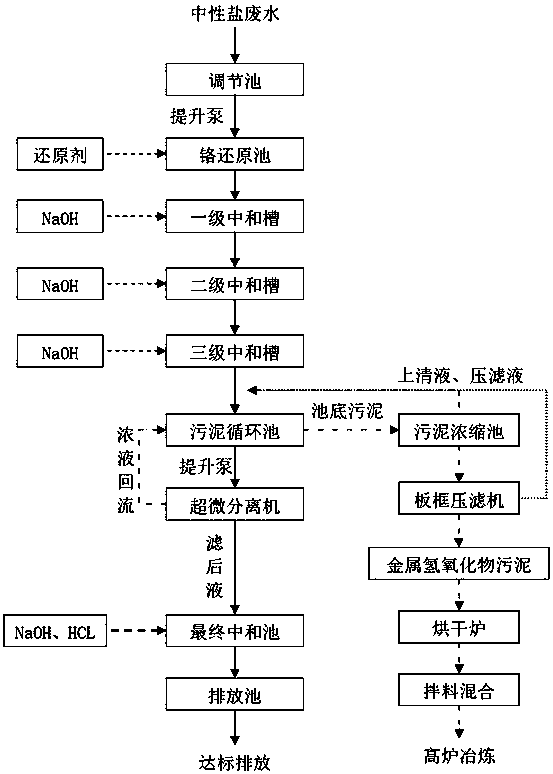

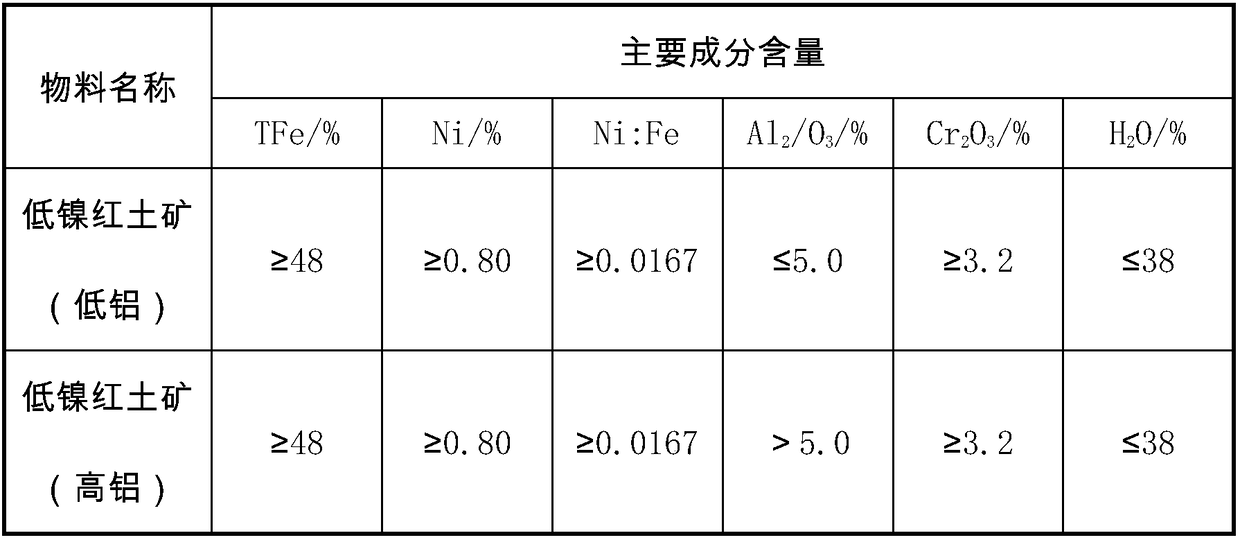

Method for recycling neutral salt wastewater produced by metal pickling

InactiveCN108178366ALow costReduce dosageSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeTreatment costs

The invention discloses a method for recycling metal hydroxide sludge resources generated from neutral salt wastewater produced by pickling in iron and steel industry after neutralization with liquidalkali. The method comprises the following steps: firstly, the neutral salt wastewater is reduced, and liquid alkali is added; metal hydroxide sludge (with solid content being 50%) is obtained after concentration with an ultra-micro separator and filter pressing with a filter press and stirred and blended with raw materials for smelting stainless steel, a product is fed into a blast furnace (or anelectric furnace) for direct smelting of stainless steel after meeting the furnace feeding requirement, valuable metal ions in the neutral salt wastewater can be recovered, harmful and hazardous solid waste is not produced, waste is changed into wealth, economic benefits of sewage treatment are increased, and treatment cost is reduced.

Owner:YIXING XINDE ENVIRONMENTAL PROTECTION TECH

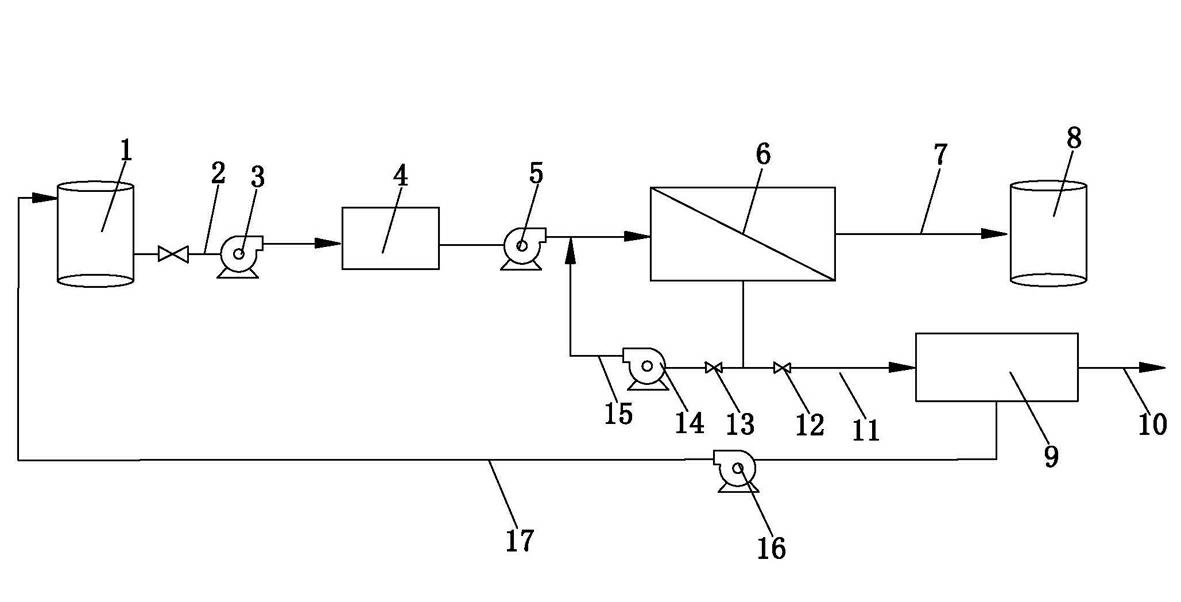

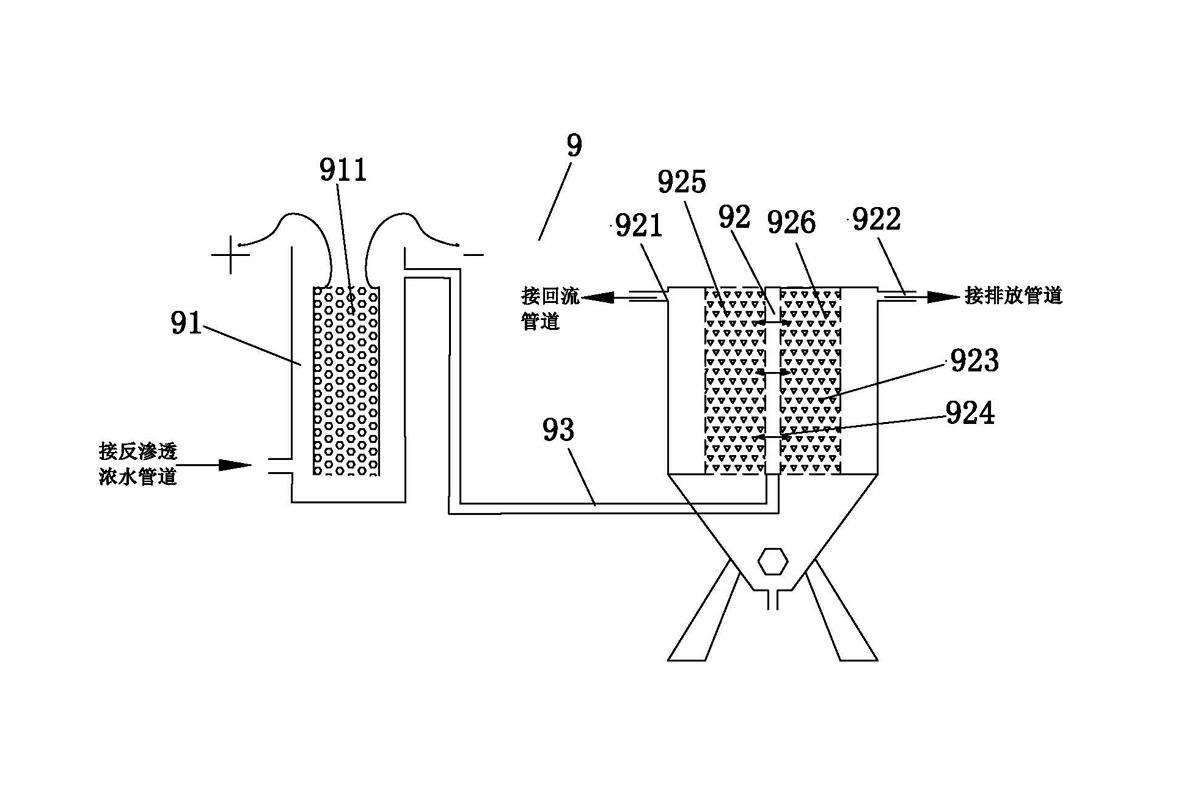

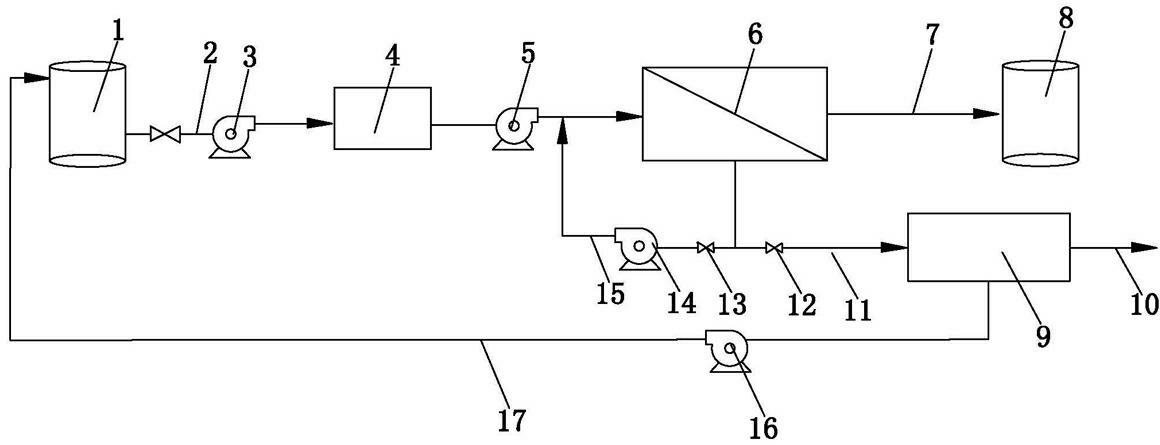

Recycled water recycling equipment and process

ActiveCN102219321AAnti-pollutionHigh recovery rateMultistage water/sewage treatmentReverse osmosisHigh pressure

The invention discloses recycled water recycling equipment and a recycled water recycling process. The recycled water recycling equipment comprises a raw water tank, a raw water pump, a pretreatment system, a high-pressure pump and a reverse osmosis membrane component which are connected with one another sequentially through a water inlet pipeline, wherein a dialyzate outlet of the reverse osmosis membrane component is connected with a water generating tank through a water generating pipeline. The recycled water recycling equipment is characterized in that: a concentrated liquid outlet of the reverse osmosis membrane component is connected with a valve and a circulating pump through a concentrated pipeline and then is connected with a pipeline behind the high-pressure pump; the concentrated liquid outlet of the reverse osmosis membrane component is connected with a valve and a three-dimensional electric catalyst system through a pipeline; one outlet of the three-dimensional electric catalyst system is connected with a delivery pump through a backflow pipeline and then is connected with a raw material tank; and the other outlet of the three-dimensional electric catalyst system is connected with a drainage pipeline. The equipment and the process have the two-level circulation characteristic and have the advantages that: the recovery ratio is high; pollution is resisted; concentrated water can be directly drained after being treated, and the like; the whole process is used for treating recycled water; and the water recovery ratio is over 90 percent.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

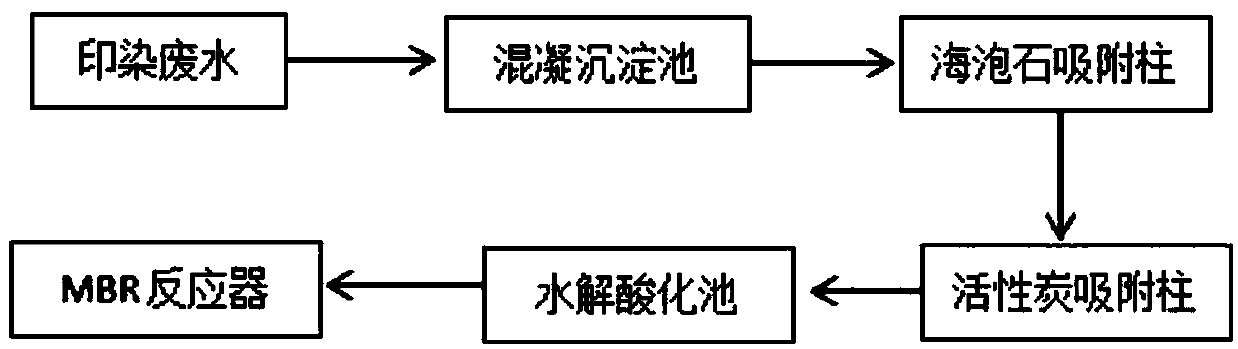

Process for treating printing and dyeing wastewater through combination of MBR and membrane separation method

InactiveCN107640874AReduce separation efficiencyDirect dischargeMultistage water/sewage treatmentTreatments waterChemistry

The invention discloses a process for treating printing and dyeing wastewater through combination of MBR and a membrane separation method. The process comprises the concrete steps of directly pumpingthe printing and dyeing wastewater into a coagulative precipitation tank, and removing suspended solids or colloidal particles through a combined action of flocculating agents i.e. polymerization ferric chloride and carboxymethyl chitosan in the coagulative precipitation tank; pumping a supernate at the upper part of the coagulative precipitation tank into a cyclic adsorption column; feeding the supernate adsorbed by the cyclic adsorption column into a hydrolysis acidification pool, carrying out hydrolysis acidification to obtain secondary sewage, and converting dye molecules difficult to degrade into micromolecules easy to biodegrade under the action of a lot of hydrolytic bacteria and acid-forming bacteria in the hydrolysis acidification pool; pumping the secondary sewage into an aerobiotic MBR reactor, wherein water obtained after treatment can be directly discharged. According to the process provided by the invention, the printing and dyeing wastewater is flocculent precipitated, adsorbed and acidized, and is then filtered and separated through a hollow fiber membrane module in the MRR reactor, the separated macromolecule organic matters are degraded through microorganisms in the reactor, and the obtained treatment water can be discharged directly.

Owner:安徽名创新材料科技有限公司

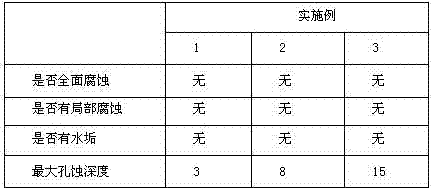

Scale-removing and anti-scale agent for pipelines

InactiveCN107055820AStrong stabilityWide range of applicationsSpecific water treatment objectivesTreatment using complexing/solubilising chemicalsSodium polyacrylateSolvent

The invention discloses a pipeline descaling and antiscaling agent, which comprises various components and the parts by weight of the components are respectively: 4-10 parts by weight of pre-film agent, 3-9 parts by weight of deoxidizer, and scale inhibition 1-5 parts by weight of agent, 2-9 parts by weight of pH regulator, and 70-92 parts by weight of solvent. The pre-filming agent is composed of one or more of zinc sulfate, zinc chloride, and sodium silicate, and the deoxidizer is composed of one or more of azodicarbonamide, sodium sulfite, and isoascorbic acid. The scale inhibitor is composed of one or more of ammonium triacetate, disodium edetate, and sodium polyacrylate, and the pH regulator is composed of one or both of sodium hydroxide and potassium hydroxide Composition, described solvent is water. The descaling and antiscaling agent of the invention has strong stability, long service life, no corrosion effect on pipelines, environmental protection, low price and good effect of descaling and antiscaling.

Owner:苏州启德胜环保科技有限公司

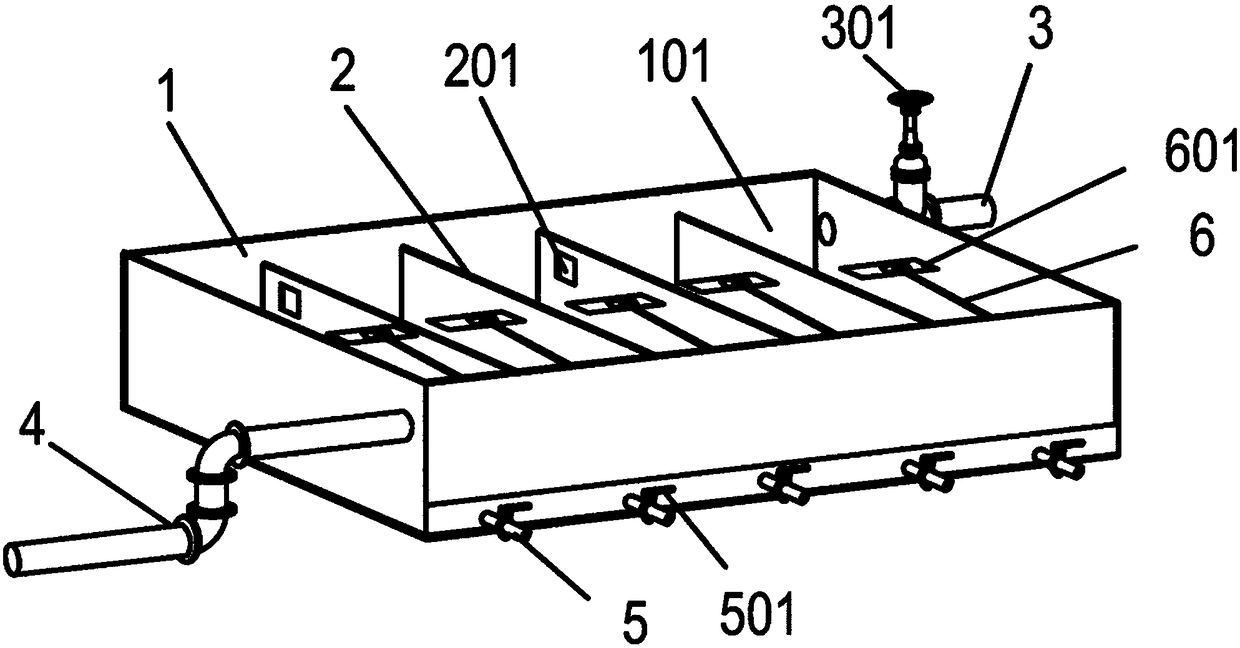

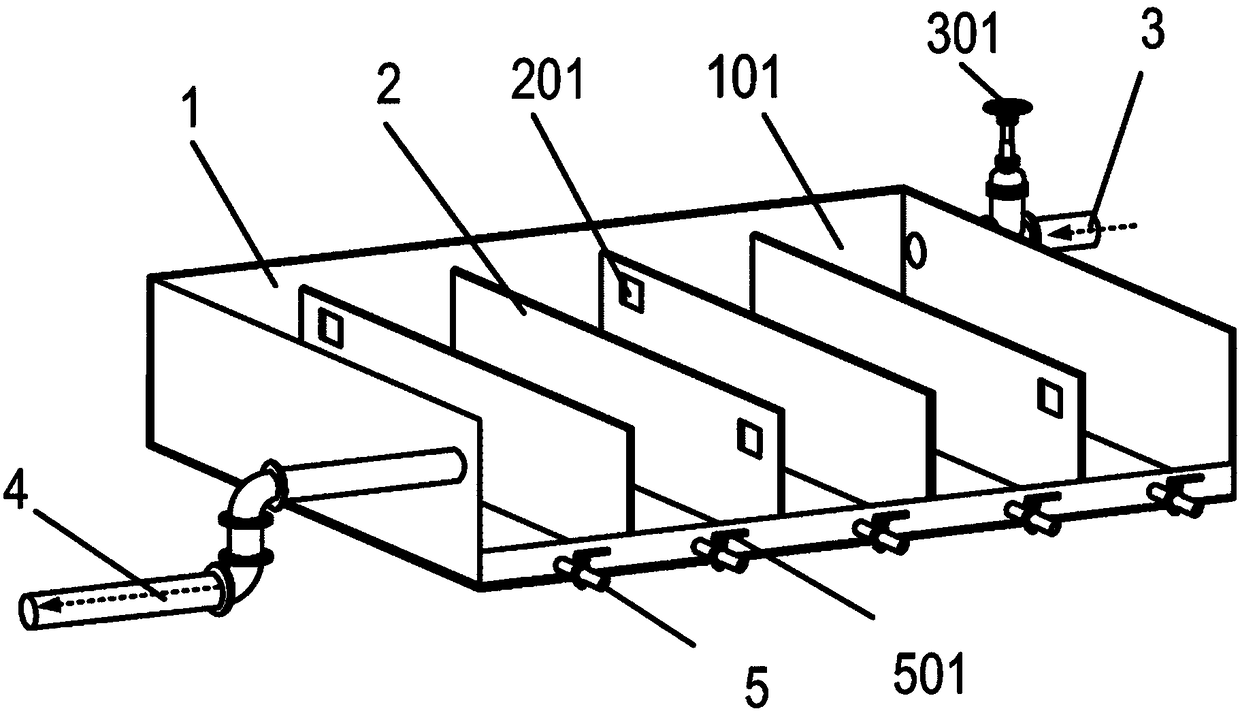

Wastewater sedimentation basin and wastewater treatment method

InactiveCN109205814ADirect dischargeFatty/oily/floating substances removal devicesTreatment involving filtrationIndustrial waste waterSolid particle

The invention discloses a wastewater sedimentation basin and a wastewater treatment method. The wastewater sedimentation basin includes a wastewater treatment tank, a water inlet pipe and a water outlet pipe that are communicated with the space inside the wastewater treatment tank, and also includes at least two partition plates. The water inlet pipe and the water outlet pipe are respectively arranged on two opposite side walls of the wastewater treatment tank, the partition plates are sequentially disposed in the space between the water inlet pipe and the water outlet pipe in the tank, and divide the space inside the wastewater treatment tank into at least three water troughs. The partition plates are equipped with overflow ports, and the overflow ports of two adjacent partition plates are staggered, and the overflow ports are internally equipped with a filter device. The wastewater sedimentation basin and the wastewater treatment method provided by the invention can remove most of the suspended oil stains and solid particle impurities in industrial wastewater, and without considering other environmental protection factors, the treated industrial wastewater can be discharged directly.

Owner:深圳市洁灏环保科技有限公司

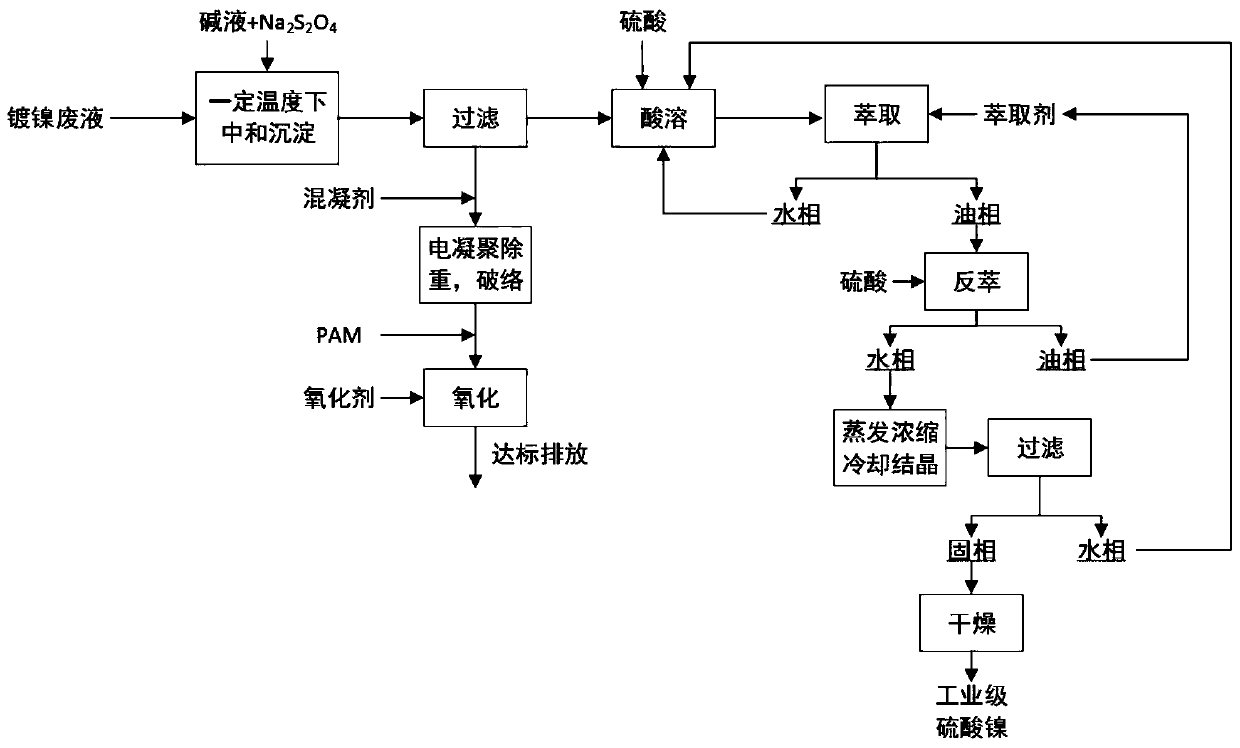

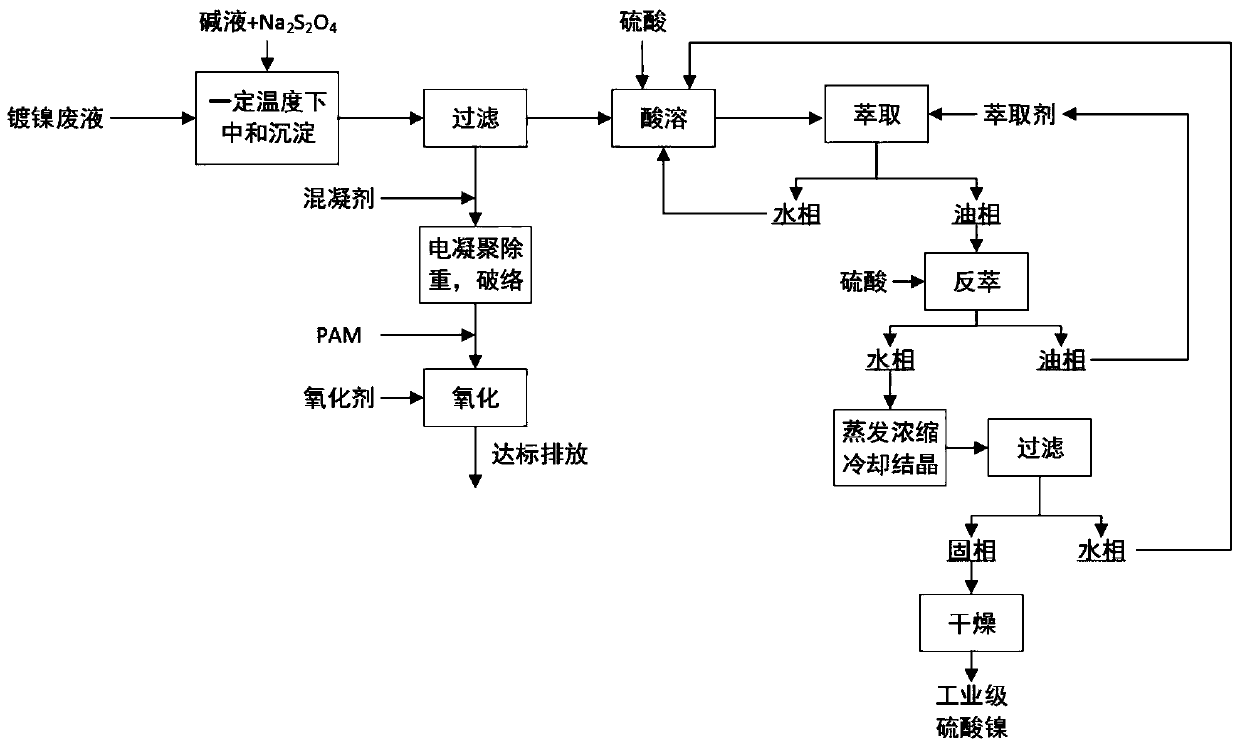

Method for recovering nickel sulfate from nickel electroplating waste liquid

InactiveCN111170499AReduce doseLow pHWater contaminantsTreatment involving filtrationSodium dithioniteSulfate

The invention discloses a method for recovering nickel sulfate from nickel electroplating waste liquid. The method comprises the following steps: (1) adding alkali liquor and sodium hydrosulfite intothe nickel electroplating waste liquid, carrying out heating and stirring, and carrying out solid-liquid separation after a reaction to obtain filter residues and a filtrate; (2) carrying out acid dissolution on the filter residues to obtain an acid-soluble solution, wherein a pH value of an acid dissolution end point is 5 or below; (3) adding an extraction agent into the acid-soluble solution toextract nickel so as to obtain a water phase and an oil phase enriched with nickel ions, and adding sulfuric acid into the oil phase enriched with the nickel ions for reverse extraction so as to obtain a nickel sulfate solution; and (4) carrying out evaporation concentration, cooling crystallization and solid-liquid separation on the nickel sulfate solution to obtain a liquid phase and a solid phase, and collecting the solid phase to obtain nickel sulfate. According to the method, on the premise that the treatment cost of the nickel electroplating waste liquid of an enterprise is greatly reduced, high-quality and high-value byproducts can be obtained, and an economic value is high.

Owner:湖南中冶艾迪环保资源开发有限公司

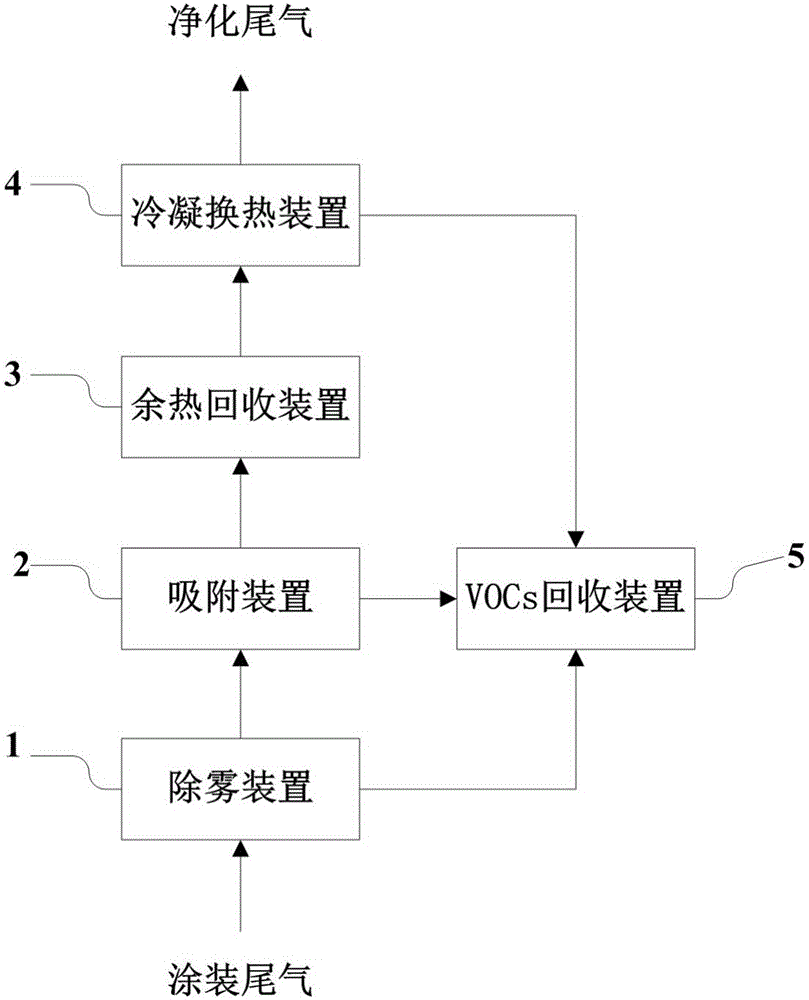

System and method for treating coating exhaust and coating equipment provided with system

InactiveCN106311572AReasonable useReduce energy consumptionGas treatmentDispersed particle separationProcess engineeringEnergy consumption

The invention discloses a system and method for treating coating exhaust and coating equipment provided with the system, and relates to the field of treatment of industrial exhaust. The system for treating coating exhaust comprises a demisting device, an adsorption device, a waste heat recovery device, a condensation heat exchange device and a VOCs recovery device. The demisting device, the adsorption device, the waste heat recovery device and the condensation heat exchange device are connected in sequence. The demisting device, the adsorption device and the waste heat recovery device are all connected with the VOCs recovery device. The VOCs recovery device is used for recovering VOCs, recovered by the demisting device, the adsorption device and the condensation heat exchange device, of coating exhaust. The waste heat recovery device is used for exchanging heat with coating exhaust passing through the adsorption device. The condensation heat exchange device is used for conducting condensation heat exchange on coating exhaust passing through the waste heat recovery device. By the adoption of the system and method for treating coating exhaust and the coating equipment provided with the system, production energy consumption and production cost can be effectively reduced under the condition that the production efficiency is not affected; and meanwhile, VOCs are effectively removed, and the requirement for environment protection is met.

Owner:WUHAN DONGSHENG JIENENG TECH

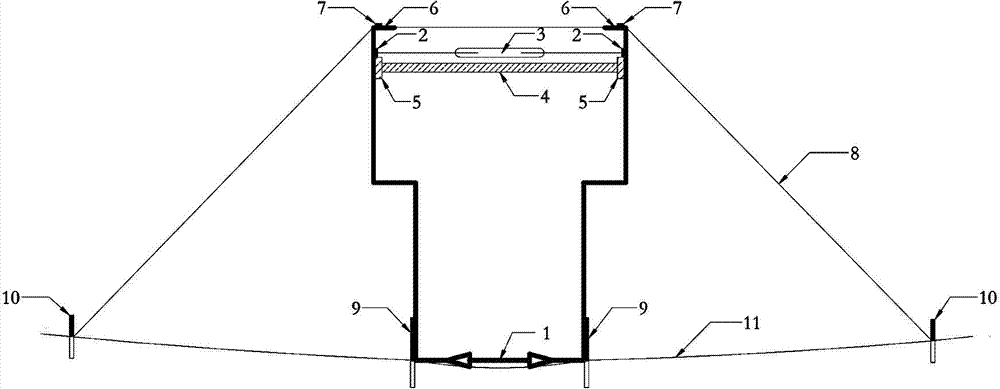

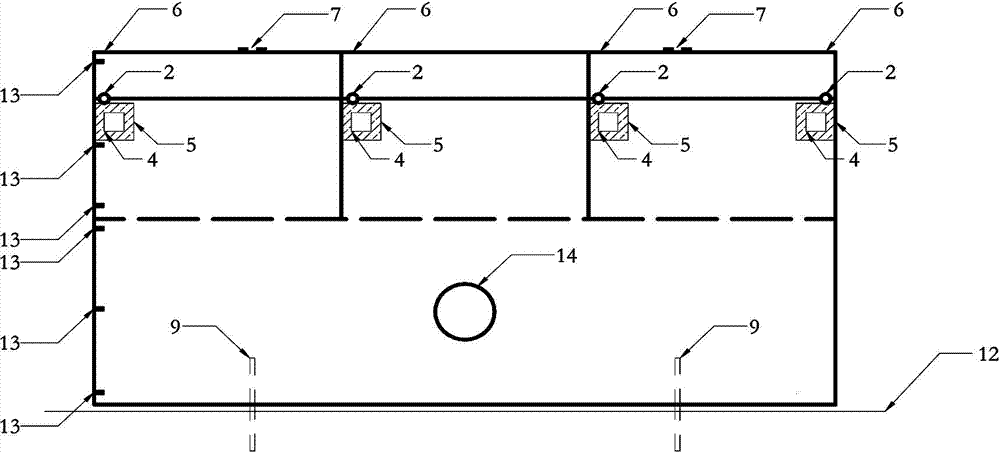

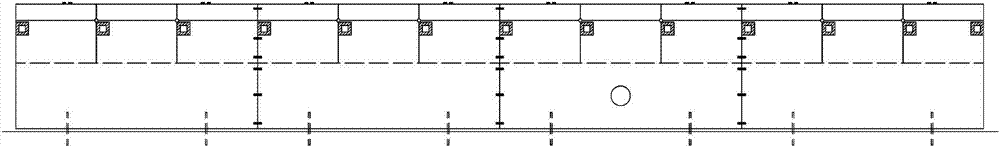

Inserted convex integral central drainage ditch device in road tunnel

The invention discloses an inserted convex integral central drainage ditch device in a road tunnel. The inserted convex integral central drainage ditch device comprises steel templates, a movable hinge, a turnbuckle, square timber cross arms and skids, wherein the two steel templates are arranged symmetrically; the bottom ends of the two steel templates are connected through the movable hinge; the upper ends of the two steel templates are fixedly connected through the turnbuckle, the square timber cross arms and the skids. The concept of water prevention and drainage is implemented in a template, so that structural drainage is realized, the effects of 'combination of prevention and blockage and rapid drainage' are achieved, problems of a central ditch system are prevented fundamentally, the stability and durability of a tunnel structure are ensured, and the operation and all-life effect of the tunnel are enhanced.

Owner:GANSU ROAD&BRIDGE NO 4 HIGHWAY ENG

Acidic wastewater treatment device for researching non-ferrous metal alloy material

PendingCN110697950AImprove filtering effectGood mixing effectWater treatment parameter controlTreatment involving filtrationEnvironmental chemistryWater pipe

The invention relates to the technical field of wastewater treatment devices, and discloses an acidic wastewater treatment device for researching non-ferrous metal alloy materials. The treatment device comprises a filter box, a neutralization box, an electrolytic box and a water storage tank, wherein a left side surface of the neutralization box is fixedly connected with a first supporting plate,the filter box is fixedly connected to the top of the first supporting plate, two filter plates are fixedly connected inside the filter box, a filter screen is arranged between the two filter plates,and the top of the filter box is communicated with a liquid inlet pipe; and a second supporting plate is fixedly connected to a right side surface of the neutralization box. By arranging the filter box, the filter plates, the filter screen, the liquid inlet pipe, a water through hole and a water pipe, the acidic wastewater is injected into the filter box through the liquid inlet pipe and is blocked by the filter plates, the acidic wastewater is slowly filtered from the filter screen through the water through hole, so that the filtering effect is improved, and the filtered acidic wastewater enters the neutralization box through the water pipe.

Owner:CHANGDE XINRUI NEW MATERIAL CO LTD

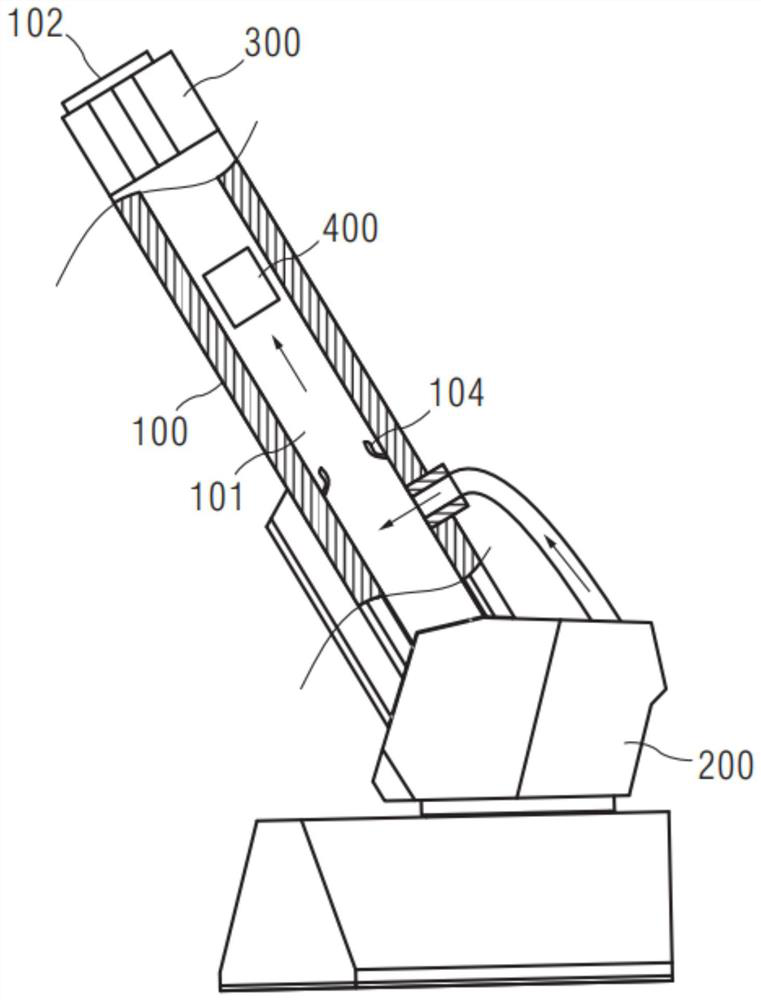

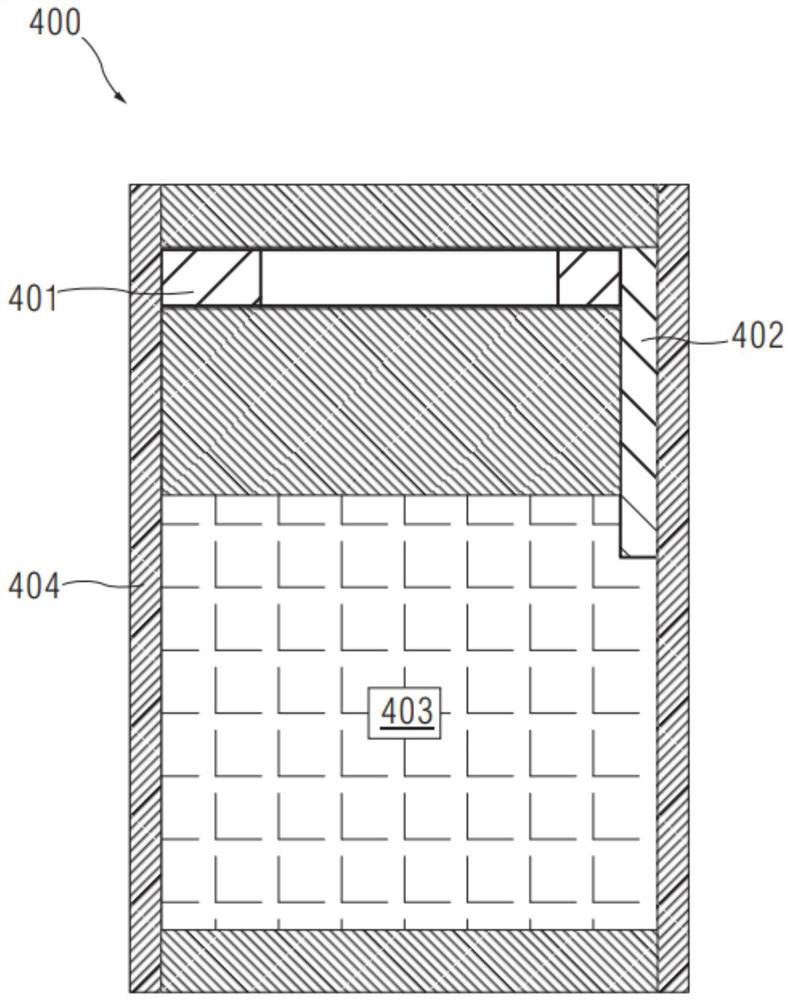

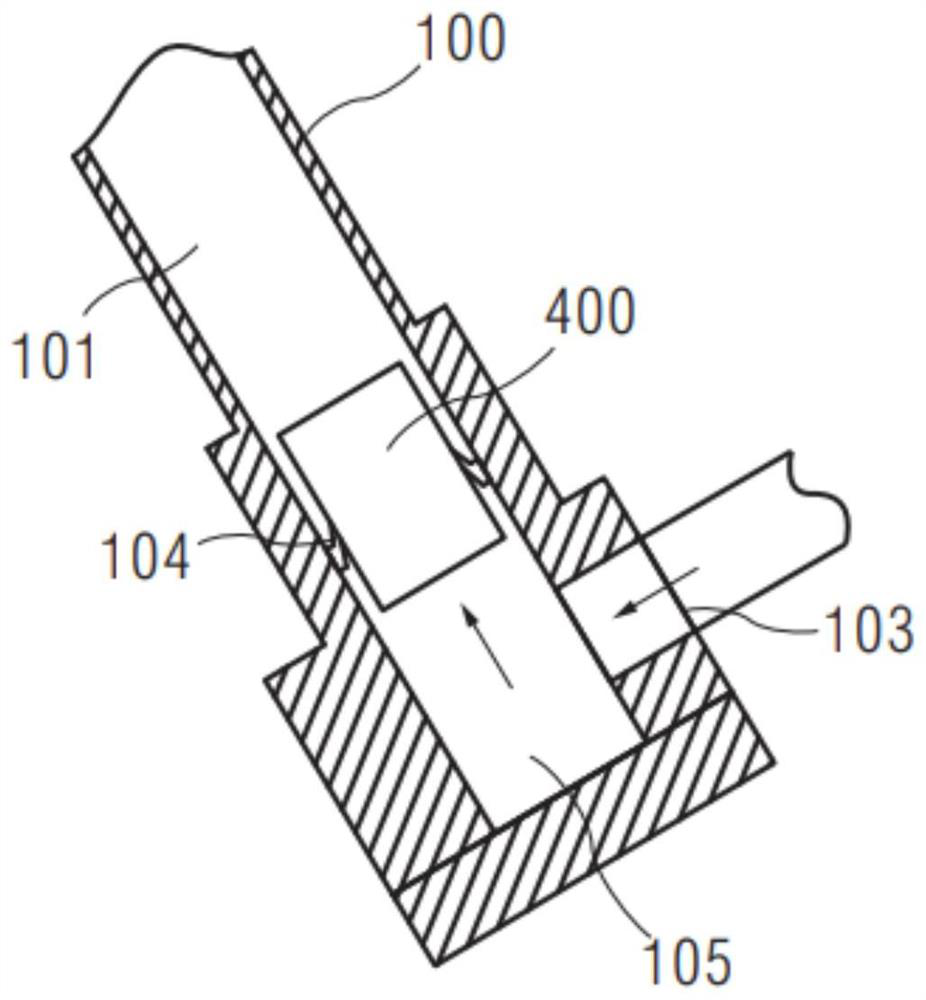

Pneumatic bird-repelling bullet firing device

The invention discloses a pneumatic bird-repelling bullet firing device, and belongs to the technical field of bird-repelling equipment. Bird-repelling bullets used in cooperation with the pneumatic bird-repelling bullet firing device are provided with fuses, and the pneumatic bird-repelling bullet firing device comprises a firing tube, a gas supply unit and a non-contact ignition device, wherein the firing tube is internally provided with a bullet body movement channel, the bullet body movement channel communicates with the outside world through an outlet end of the firing tube, and the firing tube is further provided with a gas inlet which communicates with the bullet body movement channel; the gas supply unit can provide compressed gas for the bullet body movement channel through the gas inlet, so that the bird-repelling bullets in the bullet body movement channel are fired to the outside world through an outlet; and the non-contact ignition device is arranged outside the firing tube, and can ignite the fuses of the bird-repelling bullets which move in the bullet body movement channel in a non-contact mode. By means of the pneumatic bird-repelling bullet firing device of the structure, the efficiency of firing the bird-repelling bullets can be improved, the firing difficulty is reduced, and the firing safety is improved.

Owner:北京天上宇通科技有限公司

Method for treating organic wastewater by modified bentonite

ActiveCN105502557APH has little effectDirect dischargeWater treatment compoundsWater contaminantsWater bathsSodium Bentonite

The invention discloses a method for treating organic wastewater by modified bentonite. The method comprises the following sequential steps: 1) calcium bentonite or sodium bentonite is adopted, in terms of correspondence of each gram of bentonite to 0.5-1.0 mmol of manganese chloride bentonite sieved by a 20-50-mesh sieve is added to a manganese chloride solution with the mass percent concentration of 15%-30%, the mixture is stirred in a water bath with the constant temperature of 40-50 DEG C for 5-6 h and aged for 12-24 h, then a precipitate is separated from the liquid, washed with deionized water twice or three times and dried, and potassium permanganate modified bentonite is obtained; 1 g of the dried manganese chloride modified bentonite is taken and added to 1-1.5 L of to-be-treated organic wastewater, then 0.2-0.6 mmol of sodium bisulfite is added, the mixture is stirred for 10-20 min, 1-2 g of hydrotalcite is added, organic matters are decomposed, the precipitate is separated, and a supernatant can be drained. The method is seldom affected by the pH of the wastewater, and secondary pollution is avoided after treatment.

Owner:江苏升和环保科技有限公司

Carbonizing treatment equipment for multiple waste materials of ship and treatment process adopting carbonizing treatment equipment

ActiveCN105542809AStop pollutionLarge capacity reduction ratioSolid waste disposalSpecial form destructive distillationVacuum pumpingMedical waste

The invention discloses carbonizing treatment equipment for multiple waste materials of a ship. The carbonizing treatment equipment comprises a filtering mechanism, a solid smashing mechanism, a vacuum pumping system, an upper valve, a storage hopper, a lower valve, a carbonizing furnace, a discharging mechanism and a dust collector, wherein the filtering mechanism and the solid smashing mechanism are both connected with the upper valve; the upper valve, the storage hopper, the lower valve and the carbonizing furnace are connected sequentially from top to bottom; the carbonizing furnace is connected with the vacuum pumping system and the discharging mechanism; the discharging mechanism is connected with the dust collector. The invention further discloses a treatment process adopting the carbonizing treatment equipment to treat waste materials. The carbonizing treatment equipment and the treatment process have the advantages that the problem about treatment of the multiple waste materials such as kitchen waste, medical waste, solid waste and the like of the ship is solved, the equipment and the method have the characteristics of continuous charging as well as vacuum and carbonized operation, organic matters and volatile components in the waste materials are removed effectively in an environment-friendly manner, substance decay is avoided, a volume reduction ratio is increased, and carbon powder as a final product is convenient to store.

Owner:SHANGHAI HUIKAI ELECTRIC APPLIANCE

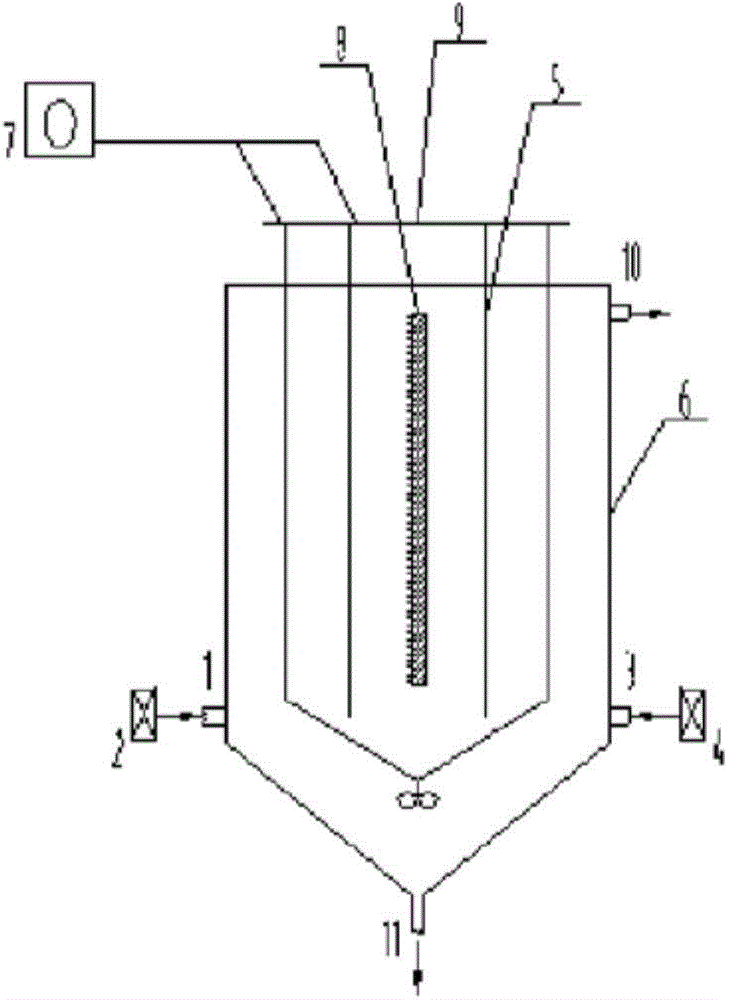

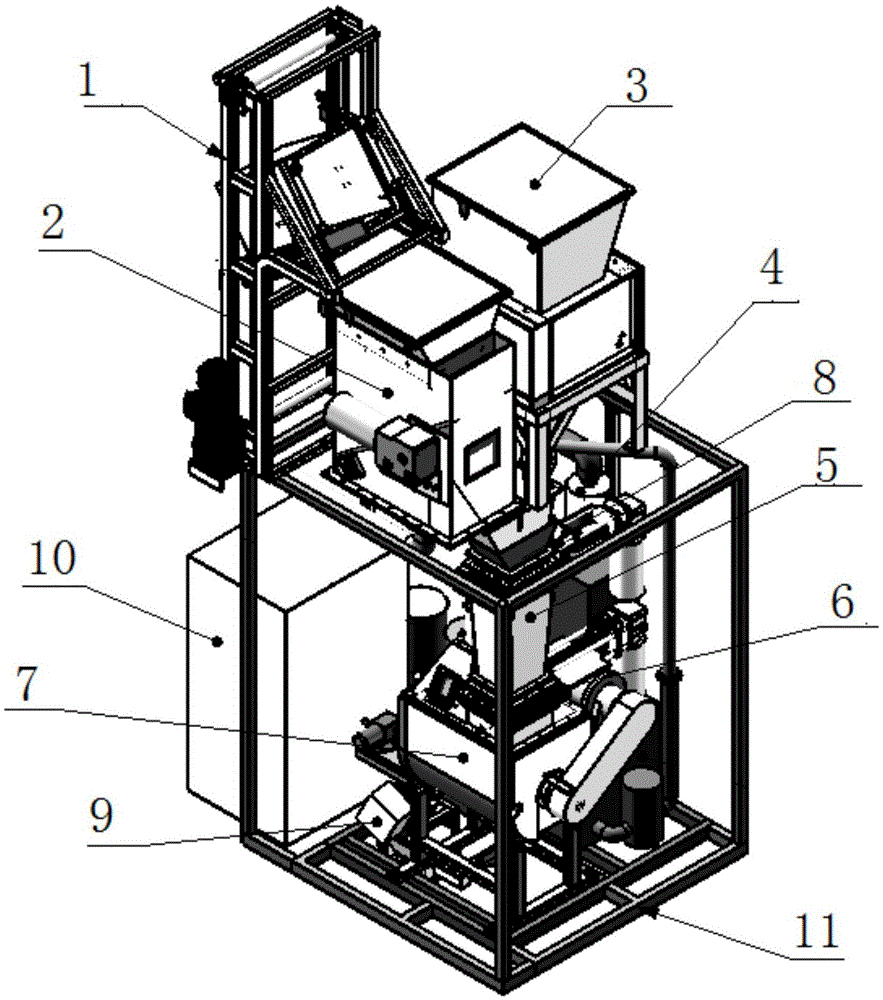

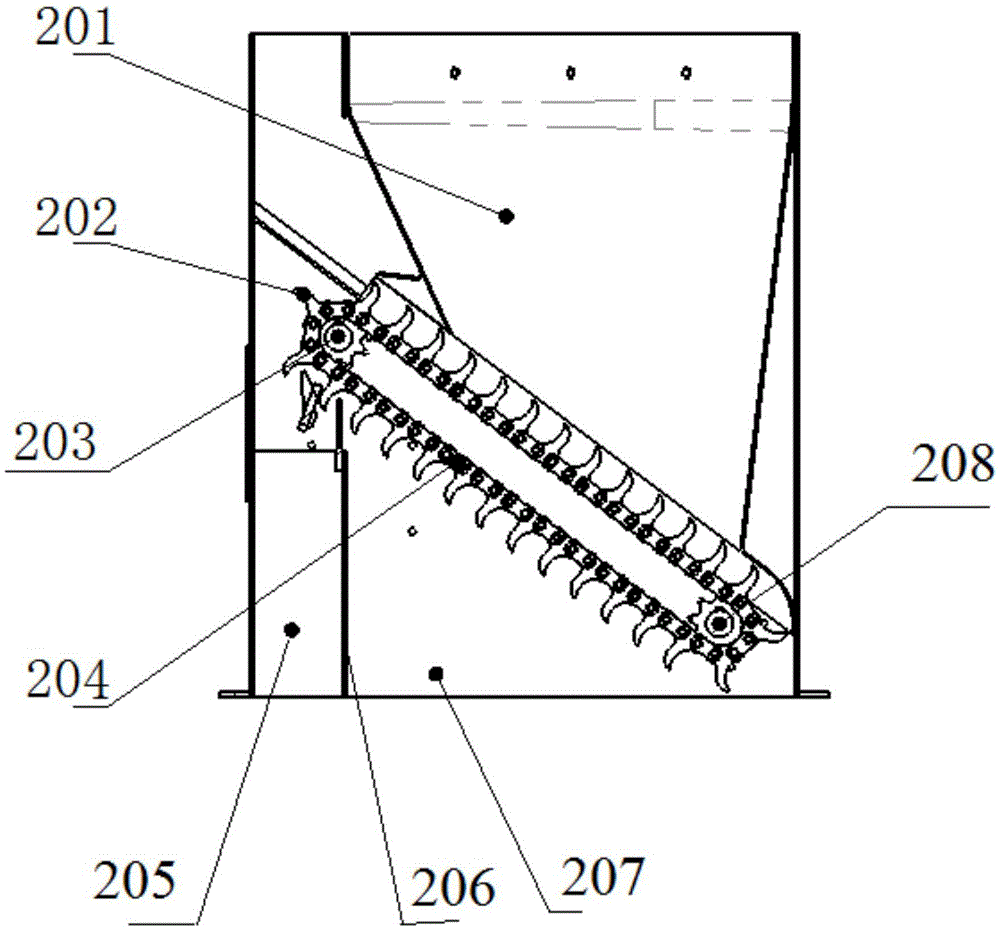

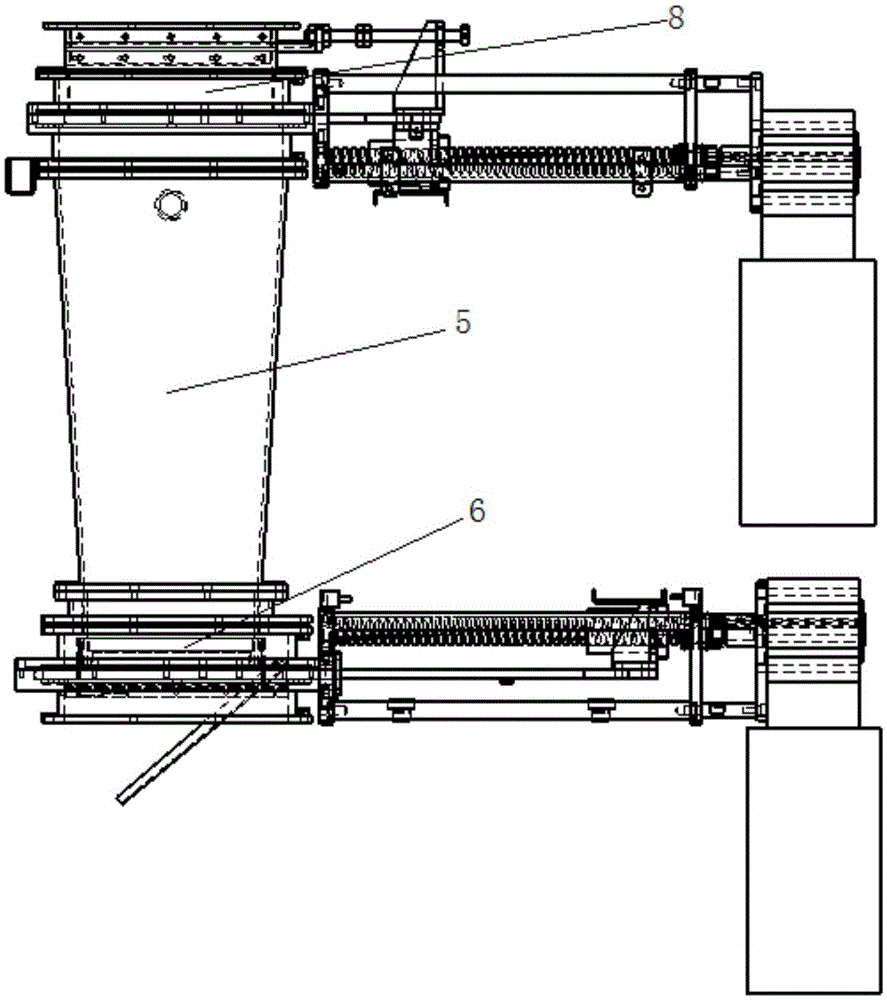

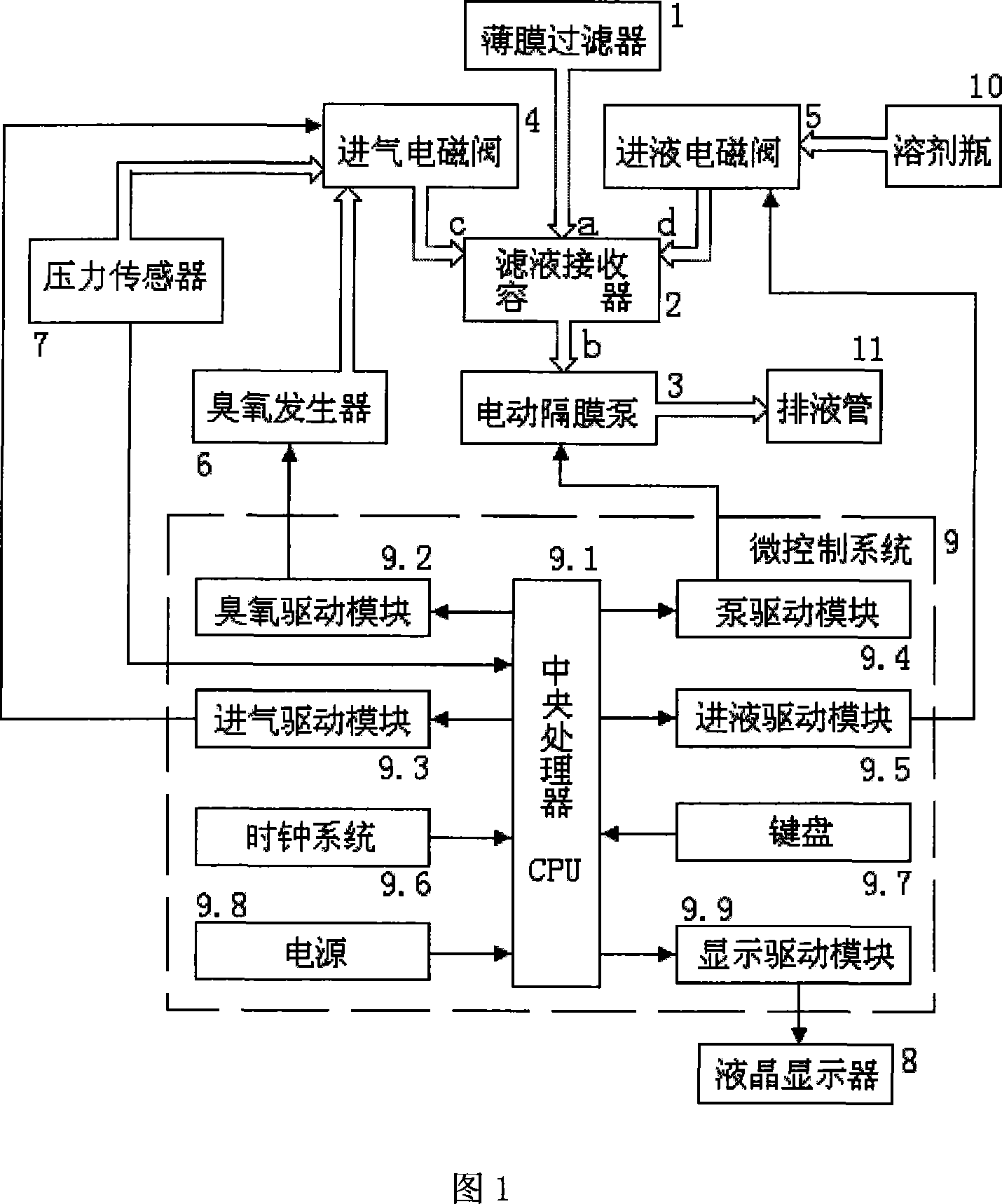

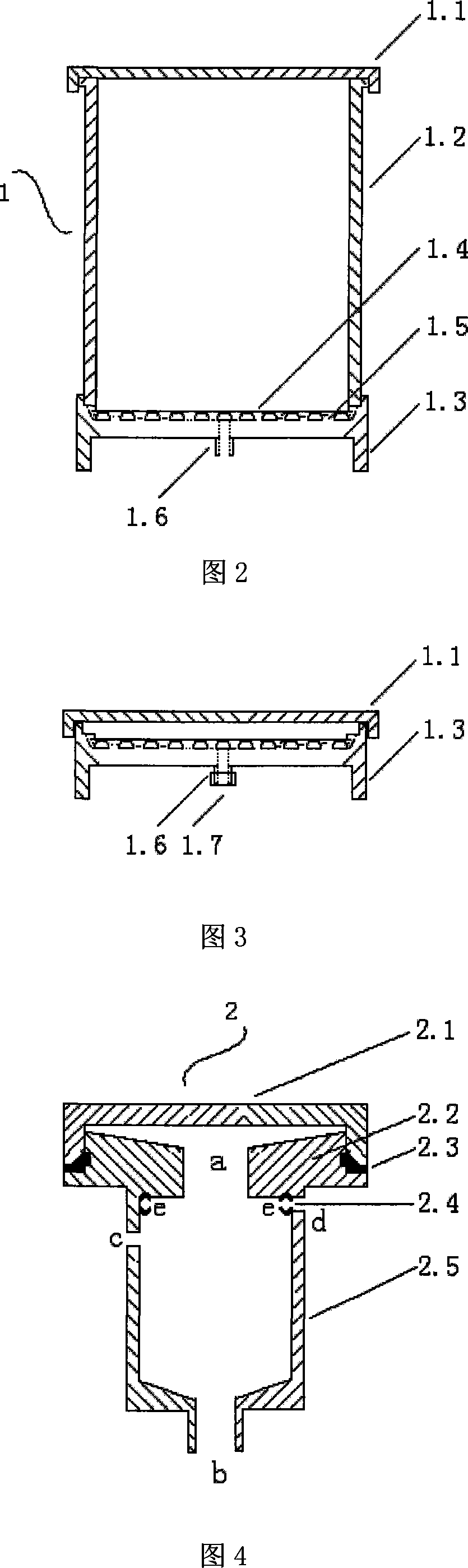

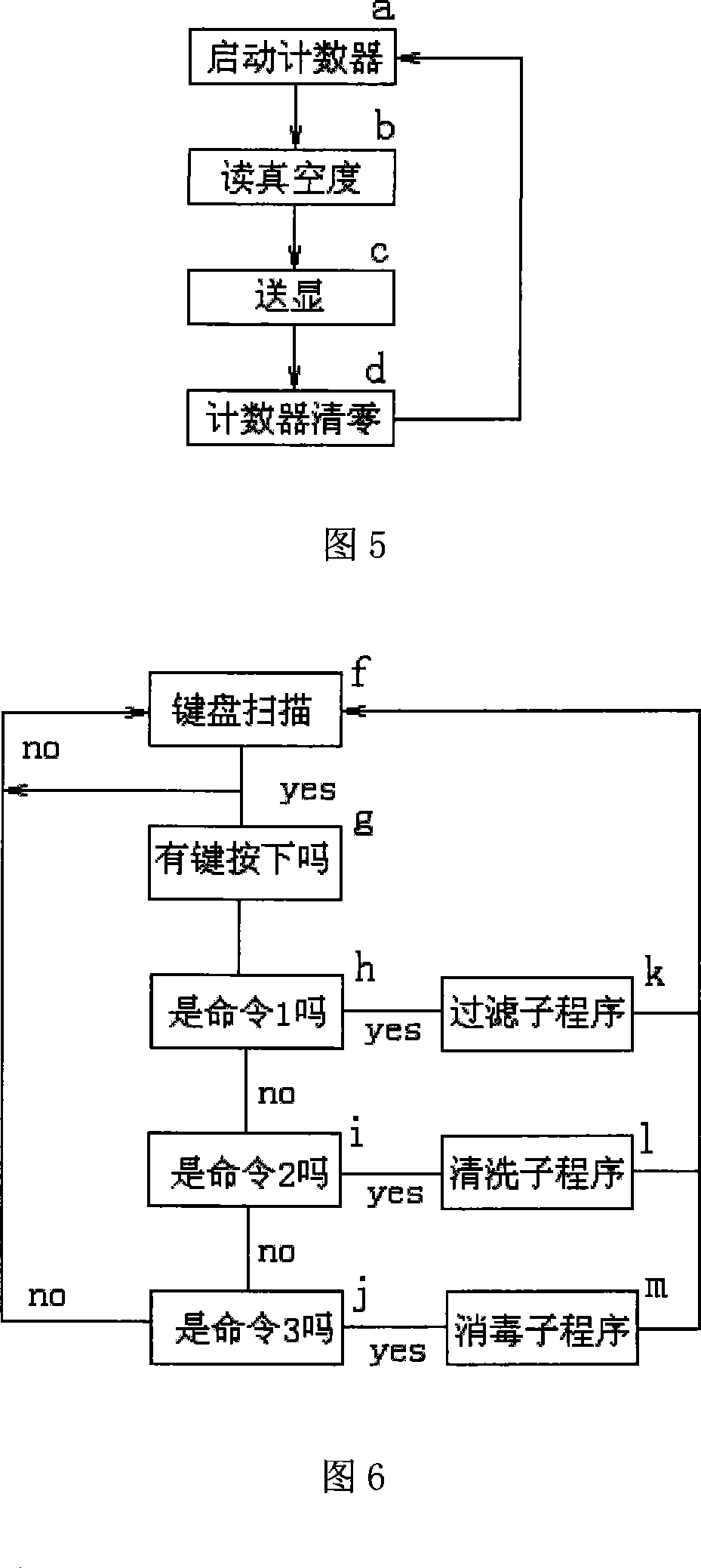

Vacuum thin film filtration and microbial cultivation device

InactiveCN101182465ADirect dischargeNo manual pouring requiredTissue/virus culture apparatusCelluloseLiquid medium

The invention discloses a vacuum membrane filtering and microorganism culturing device, which relates to an analyzing filtration and microorganism culture device. The invention applies an electric diaphragm pump as the vacuum source; the liquid medium is absorbed on the cellulose liner which is positioned below the micro-porous membrane through the vacuum membrane filtering method; the membrane filtering device is refitted into a culture dish; and the device is cleaned and sterilized automatically with the cleansing detergent and ozone. The device is a mechanical and electrical integration device, which comprises the membrane filtering device (1), a filtrate receiver (2), the electric diaphragm pump (3), an air-in electromagnetic valve (4), a liquid-in electromagnetic valve (5), an ozone generator (6), a pressure sensor (7), a liquid crystal display (8), a micro-control system (9), a solution bottle (10) and a drain pipe (11). The invention has convenient application and strong practicality; the invention avoids the busy work of dumping filtrate, transferring membrane, cleaning and sterilizing and preparing agar plate; the invention also has the characteristics of intelligence, integration and multi-function; the invention suits for filtration technology areas such as medicine and health etc.

Owner:沈佳特

Aluminum alloy scale chemical cleaning agent and preparation method thereof

The invention discloses an aluminum alloy scale chemical cleaning agent and a preparation method thereof. The aluminum alloy scale chemical cleaning agent comprises, by weight, 20-40 parts of concentrated hydrochloric acid with the mass fraction of 37%, 0.5-5 parts of lauric acid methyl ester sulfonate, 5-14 parts of methenamine, 1-3 parts of thiourea, 2-6 parts of benzotriazole, 5-15 parts of absolute ethyl alcohol and 70-90 parts of water. The components are mixed, heated and stirred to prepare the aluminum alloy scale chemical cleaning agent. The dissolving capacity for aluminum alloy scales reaches 81.6-113.5 g / Kg, the scale dissolving effect is good, the scales are cleaned up thoroughly, efficiently and safely, the hydrogen embrittlement phenomenon is not generated, the scales can be directly drained, and the environment is not polluted.

Owner:SUZHOU BEC BIOLOGICAL TECH

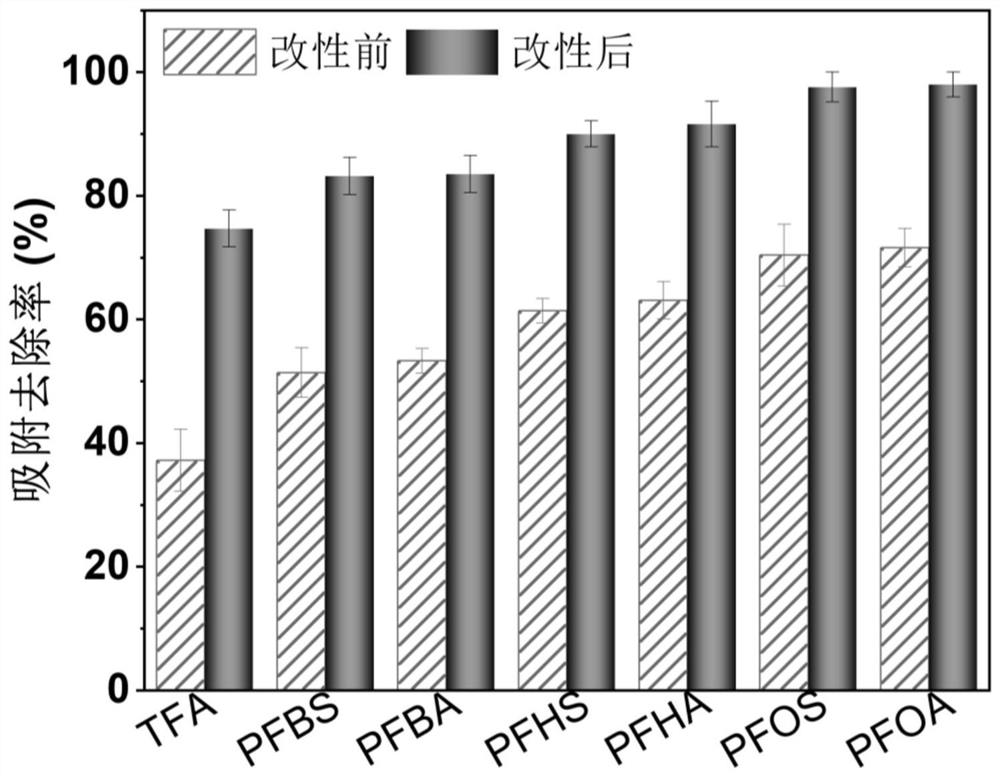

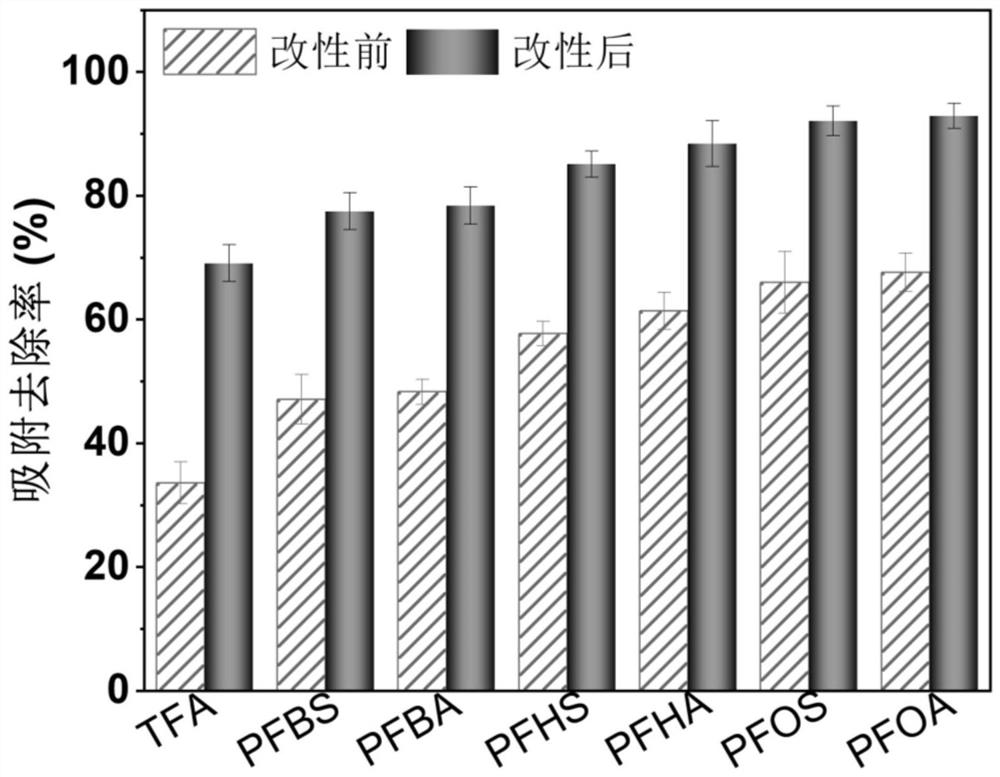

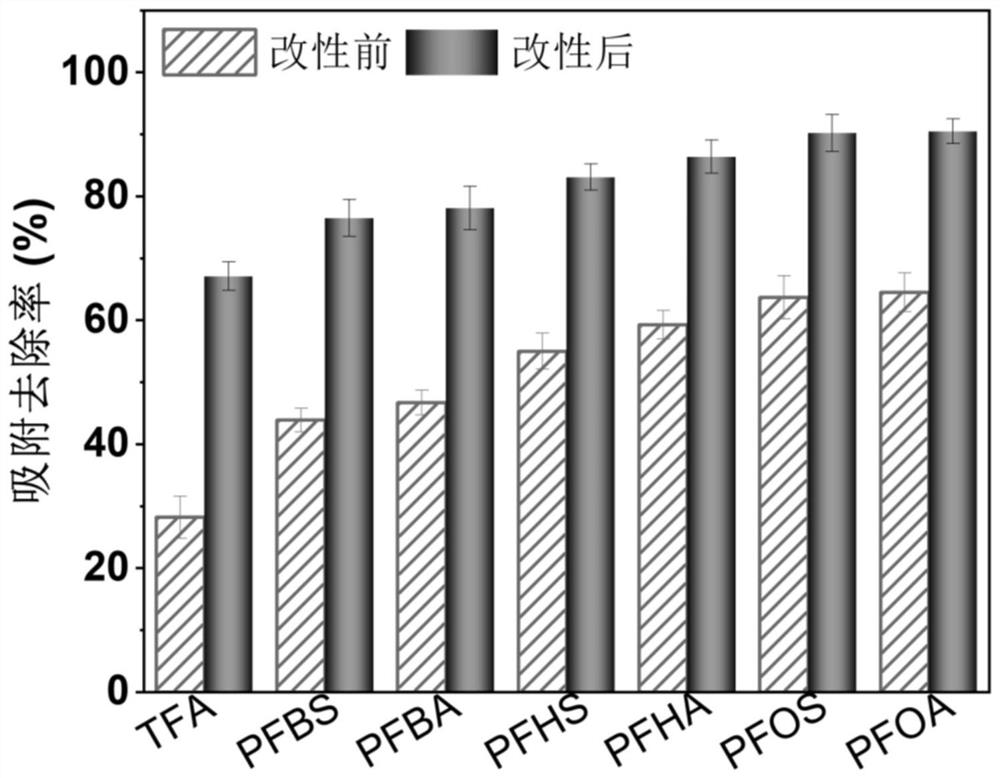

Modification method for removing perfluorocarboxylic acid in water by using reinforced activated carbon and prepared modified activated carbon

ActiveCN114832777AIncrease the saturated adsorption capacityModification method is simpleOther chemical processesWater contaminantsActivated carbonBisulfide

The invention discloses a modification method for removing perfluorocarboxylic acid in water by reinforced activated carbon, which comprises the following steps: (1) pretreating activated carbon, the pretreatment process comprising alkali washing and acid washing; (2) transferring the activated carbon pretreated in the step (1) into a graphene oxide solution to prepare graphene oxide loaded activated carbon; and (3) transferring the graphene oxide loaded activated carbon into a sulfite solution or a hydrosulfite solution, reacting under the condition of ultraviolet irradiation, and performing reduction modification to prepare the modified activated carbon. According to the method, the adsorption efficiency of the activated carbon on the perfluorocarboxylic acid is enhanced by regulating the polarity of the surface of the activated carbon, and after the activated carbon is modified by adopting the method, the removal rate of the perfluorocarboxylic acid in water is remarkably increased. The modification method disclosed by the invention is simple and efficient, mild in reaction condition, low in equipment requirement, green and environment-friendly and free from secondary pollution, and the prepared modified activated carbon has a good removal effect on perfluorocarboxylic acid in water.

Owner:ZHEJIANG UNIV

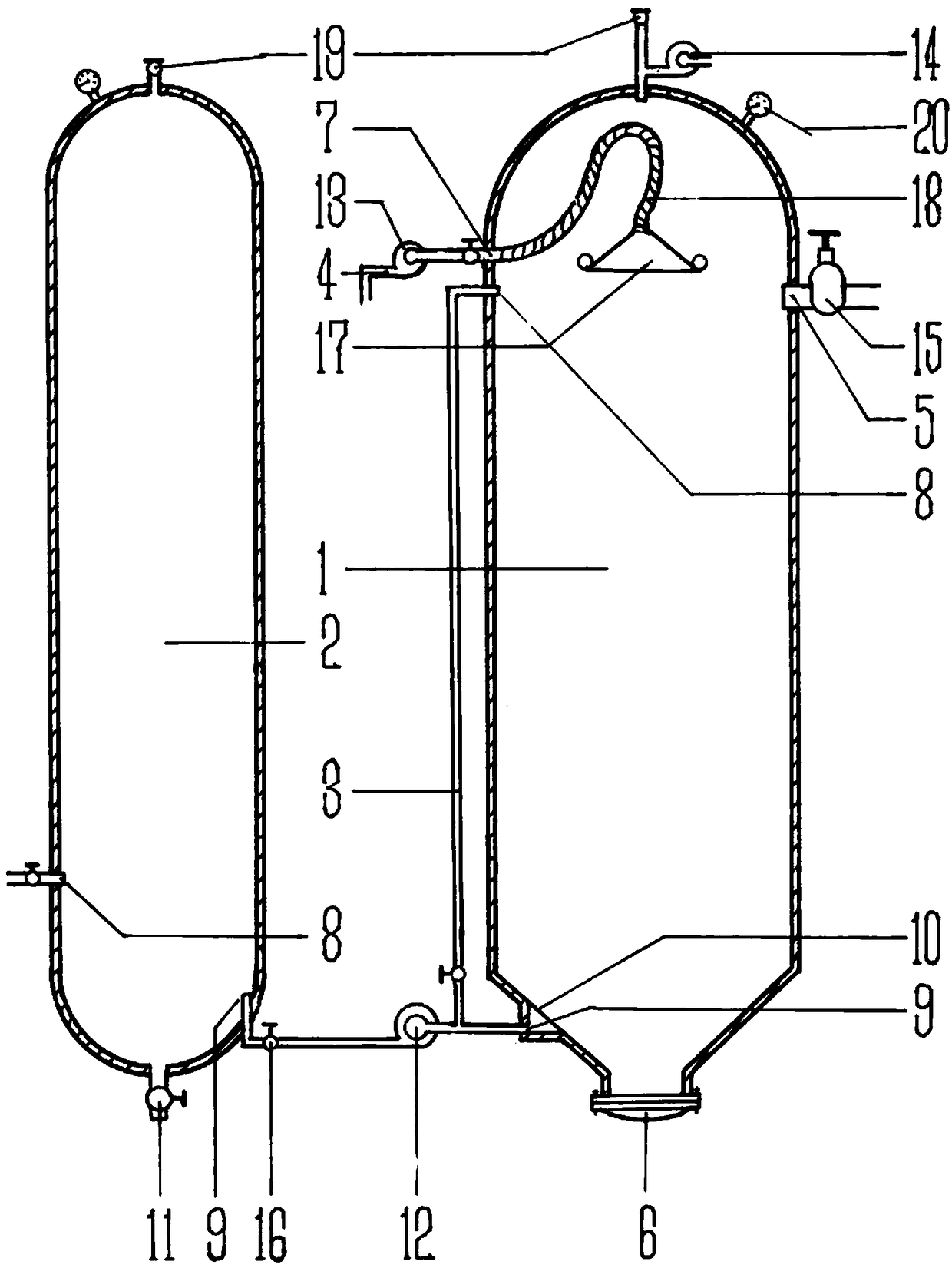

Device for separating oil-containing silt by liquid-state CO2

ActiveCN108585393AEasy to separateLow costWaste water treatment from quariesSludge treatmentHigh densityLiquid state

The invention discloses a device for separating oil-containing silt by liquid-state CO2. The device is characterized in that the physical properties of ultralow viscosity, ultrahigh flowability and seepage performance, high density and ultrahigh adsorption power of the liquid-state CO2 are used; the separation and collection of the oil-containing silt is completed in a supercritical pressure separation tower; the goals of environment protection and resource utilization are achieved. Compared with the prior art, the device has the advantages that the cost is low; the efficiency is high; the separation is thorough; the raw material sources are wide and rich. The device has the characteristics that no new harmful substance is generated in the whole processing process; the new pollution and the thus required secondary government are avoided. The special beneficial effects and action are realized on the duplex significance of environment protection and resource utilization, so that good popularization and application values are realized.

Owner:东营金岛环境工程有限公司 +1

Non-contact continuous biological dealkalization technology for red mud

ActiveCN107935340APrevent growth and reproductionAvoid Negative Effects on MetabolismBiological sludge treatmentMyceliumSlurry

The invention discloses a non-contact continuous biological dealkalization technology for red mud. The technology comprises the following steps: injecting sterilized culture medium subjected to dealkalization strain inoculation into an acid production filtering tank, setting parameters at a starting stage, entering a continuous acid production state after the starting stage is operated for certaintime, adopting continuous liquor charging and continuous liquor discharging modes, ensuring that aspergillus niger is fermented to produce acid in the acid production filtering tank, conveying produced fermentation liquor into a dealkalization tank, ensuring that mycelium pellets are singly discharged, and red mud slurry and fermentation liquor are subjected to acid-base neutralization reaction,so as to reduce the basicity of the red mud, feeding a reacted mixed material into a solid-liquid separation tank, and ensuring that dealkalization liquor and the red mud subjected to dealkalization are both neutral and can be directly discharged or recycled. The technology has the advantages that red mud does not in direct contact with mycelium, the negative effect on the growth and reproductionof the mycelium by the venensity of red mud is avoided, continuous operation ensures that strain is always in a logarithmic phase, the negative effect caused by the lag phase and decline phase of thallus is avoided, and efficient, green and low-cost running of biological dealkalization technology for red mud is realized.

Owner:LUOYANG INST OF SCI & TECH

A method for completely reclaiming tungsten trioxide in waste scr catalyst

InactiveCN104118911BReduce energy consumptionComplete desiliconizationTungsten oxides/hydroxidesChemical recyclingFlue gasSilicic acid

The invention relates to the field of flue gas denitration, and specifically relates to a method capable of completely recycling tungsten trioxide from an SCR catalyst. The method comprises the following steps: soaking grinded waste catalyst in water with a volume three to four times as large as that of the waste catalyst to remove the impurities; adding an excess alkali solution with a concentration of 60 to 80wt% into the purified powder, soaking for 3 to 5 hours at a temperature of 140 to 150 DEG C, filtering, condensing the filtrate to recycle the alkali, adding acid into the condensed liquid from which the alkali has been crystallized to adjust the pH value to a range of 7 to 8, filtering to remove the generated silicic acid so as to remove the silicon element, adjusting the pH value of filtrate to 10 or more, boiling the filtrate to carry out tungstate radicle uniformity, cooling the filtrate temperature to 60 to 80 DEG C, dropwise adding the filtrate into 8-12 mol / L nitric acid with a volume as large as that of the filtrate, cooling, and filtering so as to obtain high purity yellow tungstic acid. The method can carry out complete sodium modification on tungsten trioxide without burning, thus low level of tungsten trioxide can be completely converted into tungstic acid, moreover, and the silicon element is completely removed, so the one-time cost of factory building and operation consumption are both largely reduced.

Owner:沈阳远大固废处理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com