Method for recycling neutral salt wastewater produced by metal pickling

A technology of wastewater recovery and neutral salt, which is applied in metallurgical wastewater treatment, chemical instruments and methods, neutralization water/sewage treatment, etc., can solve the problems of low content of valuable metal salts, waste of metal resources, non-renewable utilization, etc. Achieve the effect of increasing the content of metal ions, meeting the grade requirements, and saving the cost of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

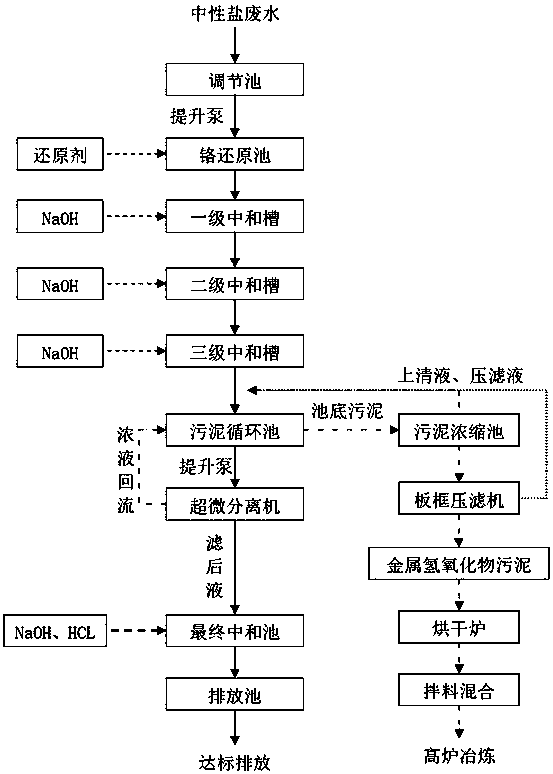

[0037] Adopt the method of the present invention to process the neutral salt wastewater discharged from the cold rolling section of a certain stainless steel factory, the concrete steps are as follows:

[0038] First of all, the pickling neutral salt wastewater discharged from the cold rolling section of a stainless steel factory was introduced into the regulating tank, and the total iron in the wastewater was measured to be 3000mg / L, the concentration of chromium ions was 640mg / L, the concentration of nickel ions was 90mg / L, and the pH was between 1 and 2. between;

[0039]Then the pickling neutral salt wastewater is pumped from the adjustment tank to the chromium reduction tank. The chromium reduction tank is divided into a primary chromium reduction tank and a secondary chromium reduction tank. The wastewater flows through the primary chromium reduction tank and the secondary chromium reduction tank in turn. In the reduction pool, add a sufficient amount of reducing agent s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com