Modification method for removing perfluorocarboxylic acid in water by using reinforced activated carbon and prepared modified activated carbon

A technology of perfluorocarboxylic acid and activated carbon, which is applied in chemical instruments and methods, water pollutants, and other chemical processes. It can solve the problems of harsh high-temperature activation reaction conditions, poor universality, and unrealized harmless treatment of PFCs. problems, to achieve the effect of low equipment requirements and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

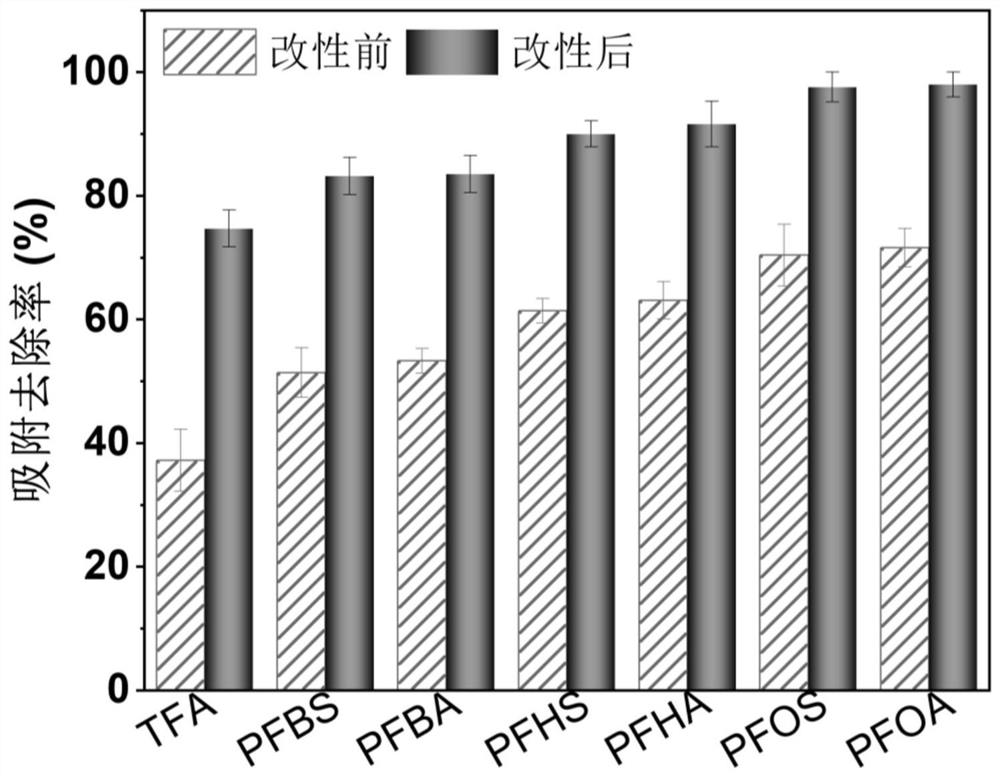

Embodiment 1

[0044] The raw coconut shell activated carbon is amorphous carbon, the particle size is 0.15-0.18mm, the pore diameter is 2-50nm, and the micropore volume accounts for 72% of the total pore volume.

[0045] The preparation method of the modified coconut shell activated carbon is as follows: the raw coconut shell activated carbon is placed in a 1.0M NaOH solution for washing for 40min, then taken out and then placed in a 50μM hydriodic acid solution (adjusting the pH value with hydrochloric acid to be equal to 2) for washing for 45min; The pretreated activated carbon was drained (no obvious water droplets dripped), and transferred to a 1 g / L graphene oxide solution (wherein the graphene oxide was a single-layer graphene oxide with an average sheet diameter of 4.5 μm and a thickness of 1.2 nm). , stirred and mixed for 30min, then separated the activated carbon from the solution, and air-dried naturally; put the graphene oxide-loaded activated carbon into the sodium sulfite soluti...

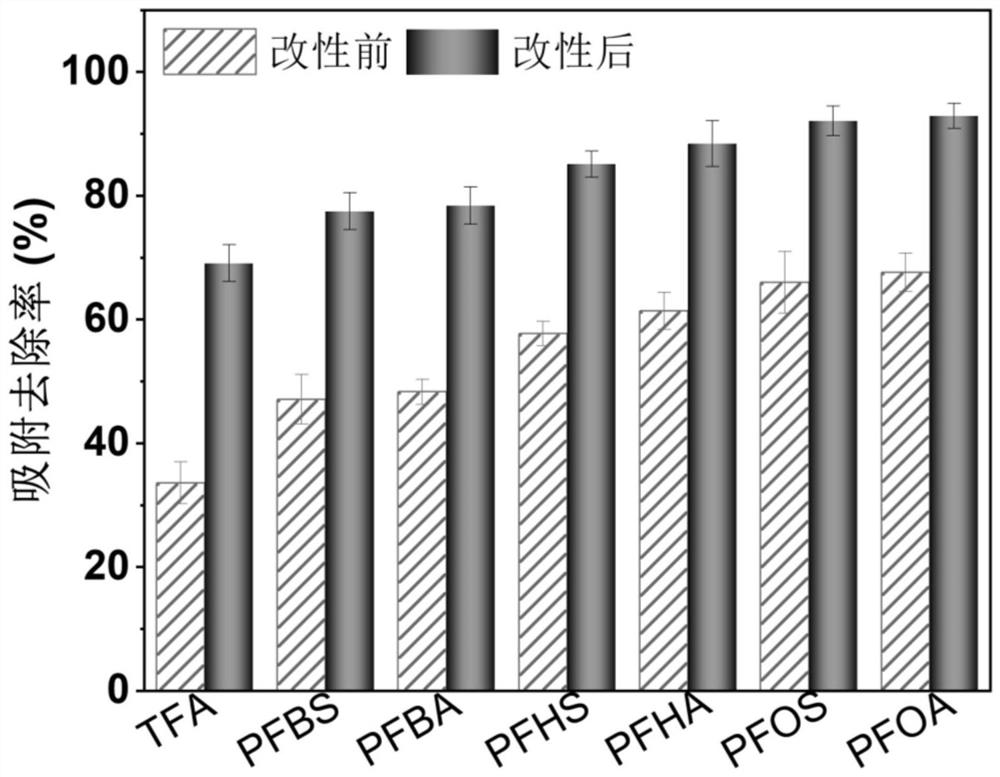

Embodiment 2

[0048] The raw wood activated carbon is amorphous carbon, the particle size is 0.4-0.8mm, the pore diameter is 2-50nm, the micropore volume accounts for 68% of the total pore volume, and the apparent density is 270g / L.

[0049] The preparation method of the modified wood activated carbon is as follows: the raw wood activated carbon is placed in a 1.0M NaOH solution for washing for 40min, taken out and then placed in a 50μM hydriodic acid solution (adjusted to pH 2 with hydrochloric acid) for washing for 45min; Drain the activated carbon (no obvious water droplets dripping), transfer to 1g / L graphene oxide solution (wherein graphene oxide is single-layer graphene oxide, the average sheet diameter is 4.5μm, the thickness is 1.2nm), stirring and mixing for 30min , then separate the activated carbon from the solution and air dry it naturally; put the graphene oxide-loaded activated carbon into 3.0mM sodium sulfite solution, keep the temperature of the reaction solution at 25°C, and...

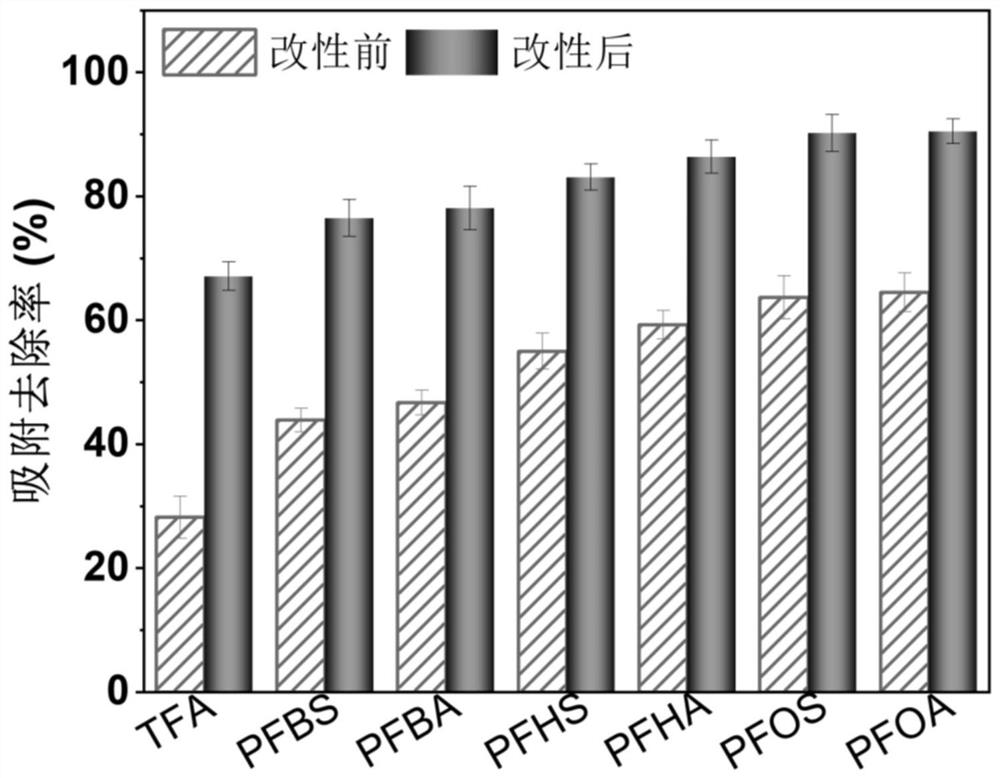

Embodiment 3

[0052] The raw anthracite activated carbon is amorphous carbon, the particle size is 0.15-0.18mm, the pore diameter is 2-50nm, and the micropore volume accounts for 68% of the total pore volume.

[0053] The preparation method of the modified anthracite activated carbon is as follows: the raw anthracite activated carbon is washed in a 1.0M NaOH solution for 40min, taken out and then placed in a 50μM hydriodic acid solution (adjusted to pH 2 with hydrochloric acid) for washing for 45min; The activated carbon was drained (no obvious water droplets dripped), transferred to 1 g / L graphene oxide solution (wherein graphene oxide was single-layer graphene oxide, the average sheet diameter was 4.5 μm, and the thickness was 1.2 nm), stirring and mixing 30min, then separate the activated carbon from the solution and air-dry it naturally; put the graphene oxide-loaded activated carbon into a 3.0mM sodium sulfite solution, keep the temperature of the reaction solution at 25°C, and turn on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com