Solidifying device and method of natural latex

A technology of natural latex and generating device, applied in the field of natural rubber rubber production, can solve the problems of strong irritating odor, strong acid corrosion, incapable of industrial application, etc., and achieve the effect of keeping the components unchanged and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

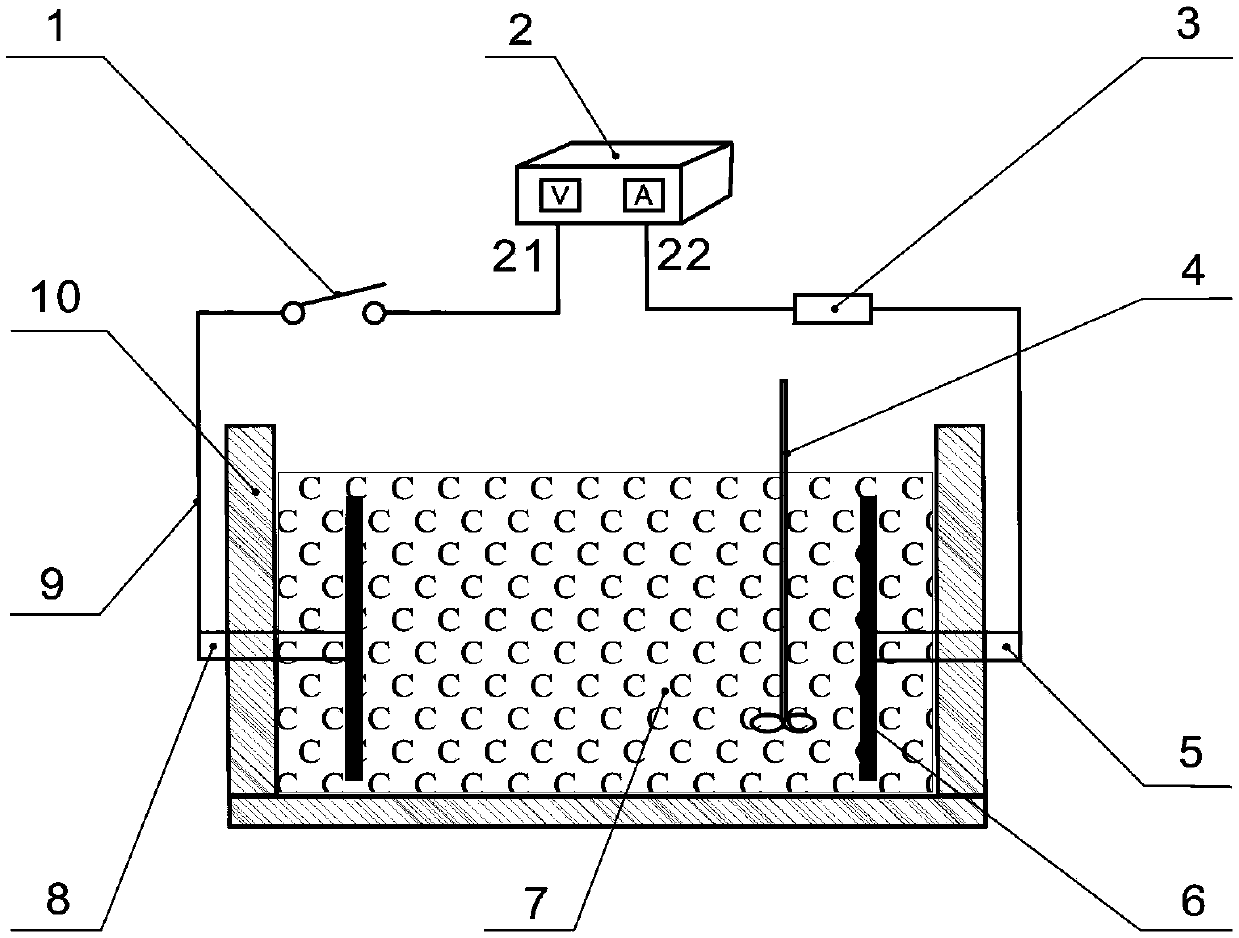

[0042] Get 50g freshly collected Hevea brasiliensis fresh latex, dry rubber content is 25.2%, ammonia preservative content is 0, is placed in the insulating container, with 10 dry cells of 1.5V as DC power supply, graphite electrode 1 is connected DC power supply positive pole , The graphite electrode II is connected to the negative pole of the DC power supply, and the two electrodes are vertically immersed in the fresh latex with a distance of 1 cm, and the DC power is connected. After 35 minutes, the fresh latex solidifies. After solidification, take out the electrodes. After testing, the main components of coagulation wastewater are soluble organic matter, protein, and amino acids.

Embodiment 2

[0045] Take 100g of concentrated latex, the dry glue content is 60%, the ammonia preservative content is 0.6%, put it in an insulating container, add water to adjust the dry glue content to 20% and stir evenly, use the battery as the DC power supply, the voltage is 64V, and the graphite electrode One end of I and graphite electrode II is connected to the same rectangular graphite plate, and the other end is respectively connected to the positive and negative poles of the DC power supply. The rectangular graphite plates are immersed in the latex in parallel with a distance of 2 cm. When the DC power is connected, after about 1 hour, the latex solidifies. After solidification, remove the electrode. After testing, the components of coagulation wastewater are mainly soluble hydrocarbon organic matter, protein, amino acid, and ammoniacal nitrogen.

[0046] Comparative example: Take 100 g of the latex in Example 2, add water to adjust the dry rubber content to 20% and stir evenly, a...

Embodiment 3

[0048] Get 2kg of concentrated latex, the content of dry glue is 60%, the content of ammonia preservative is 0.6%, put it in an insulating container, add water to adjust the content of dry glue to 20%, and use a direct current with a rectifier output voltage of 220V, copper electrode I and copper One end of the electrode II is connected to the same rectangular pure copper plate, and the other end is respectively connected to the positive and negative electrodes of the direct current. The two pure copper plates are vertically immersed in the insulating container and fully contacted with the latex. The distance between the two pure copper plates is 5cm, and the speed is 100r / min. Stir the latex, turn on the DC power supply, and after about 90 minutes, the latex solidifies, and after solidification, take out the electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com