A method for completely reclaiming tungsten trioxide in waste scr catalyst

An SCR catalyst, tungsten trioxide technology, applied in the field of flue gas denitrification, can solve the problems of increasing the primary cost and energy consumption of operation, and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

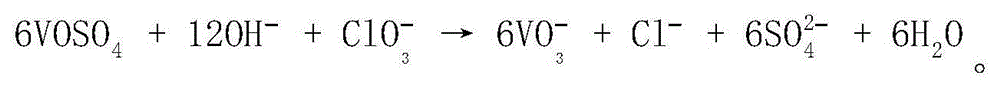

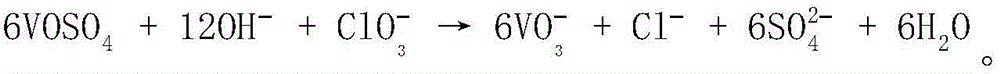

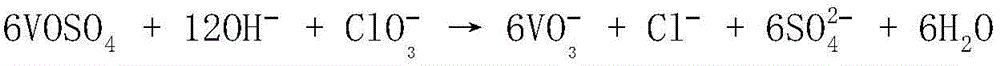

Image

Examples

Embodiment 1

[0037] In the waste SCR catalyst of this embodiment, V 2 o 5 Accounting for 1.34wt%, WO 3 Accounting for 3.02wt%, MoO 3 Accounting for 0.002wt%, TiO 2 85wt%, SiO 2 Accounting for 7.5wt%. The specific steps for completely recovering tungsten trioxide in the spent SCR catalyst are as follows:

[0038] 1) Pulverization: pulverize the waste SCR catalyst to 150 mesh and set aside.

[0039] 2) Soak powder in water to remove impurities: Soak the crushed waste SCR catalyst with 3.5 times the volume of water to remove the adsorbed arsenic, mercury, alkali metal salts and organic substances, and the filtered wastewater is adsorbed by activated carbon to absorb arsenic, mercury and organic substances. Substances can be recycled.

[0040] 3) Leaching: Add 5 times the volume of NaOH aqueous solution with a concentration of 70wt% to the wet powder after removing impurities, heat it to 145°C, soak for 4 hours, most of the vanadium, tungsten, molybdenum and titanium can be leached, so ...

Embodiment 2

[0057] In the waste SCR catalyst of this embodiment, V 2 o 5 Accounting for 1.34wt%, WO 3 Accounting for 3.02wt%, MoO 3 Accounting for 0.002wt%, TiO 2 85wt%, SiO 2 Accounting for 7.5wt%. The difference from Example 1 is that the specific steps for fully recovering the tungsten trioxide in the spent SCR catalyst are as follows:

[0058] 1) Pulverization: pulverize the waste SCR catalyst to 200 mesh and set aside;

[0059] 2) Soak powder in water to remove impurities: Soak the crushed waste SCR catalyst with 3 times the volume of water to remove the adsorbed arsenic, mercury, alkali metal salts and organic substances, and the filtered waste water is adsorbed by activated carbon to absorb arsenic, mercury and organic substances. After the substance is recycled;

[0060] 3) Leaching: add 4 times the volume of NaOH aqueous solution with a concentration of 80wt% to the wet powder after impurity removal, heat to 150°C, soak for 5 hours, vanadium, tungsten, molybdenum and titan...

Embodiment 3

[0067] In the waste SCR catalyst of this embodiment, V 2 o 5 Accounting for 1.34wt%, WO 3 Accounting for 3.02wt%, MoO 3 Accounting for 0.002wt%, TiO 2 85wt%, SiO 2 Accounting for 7.5wt%. The difference from Example 1 is that the specific steps for fully recovering the tungsten trioxide in the spent SCR catalyst are as follows:

[0068] 1) Pulverization: pulverize the waste SCR catalyst to 300 mesh and set aside;

[0069] 2) Soak powder in water to remove impurities: Soak the crushed waste SCR catalyst in 4 times the volume of water to remove the adsorbed arsenic, mercury, alkali metal salts and organic substances, and the filtered wastewater is adsorbed by activated carbon to absorb arsenic, mercury and organic substances. After the substance is recycled;

[0070] 3) Leaching: add 6 times the volume of NaOH aqueous solution with a concentration of 60wt% to the wet powder after impurity removal, heat to 140°C, soak for 3 hours, vanadium, tungsten, molybdenum and titanium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com