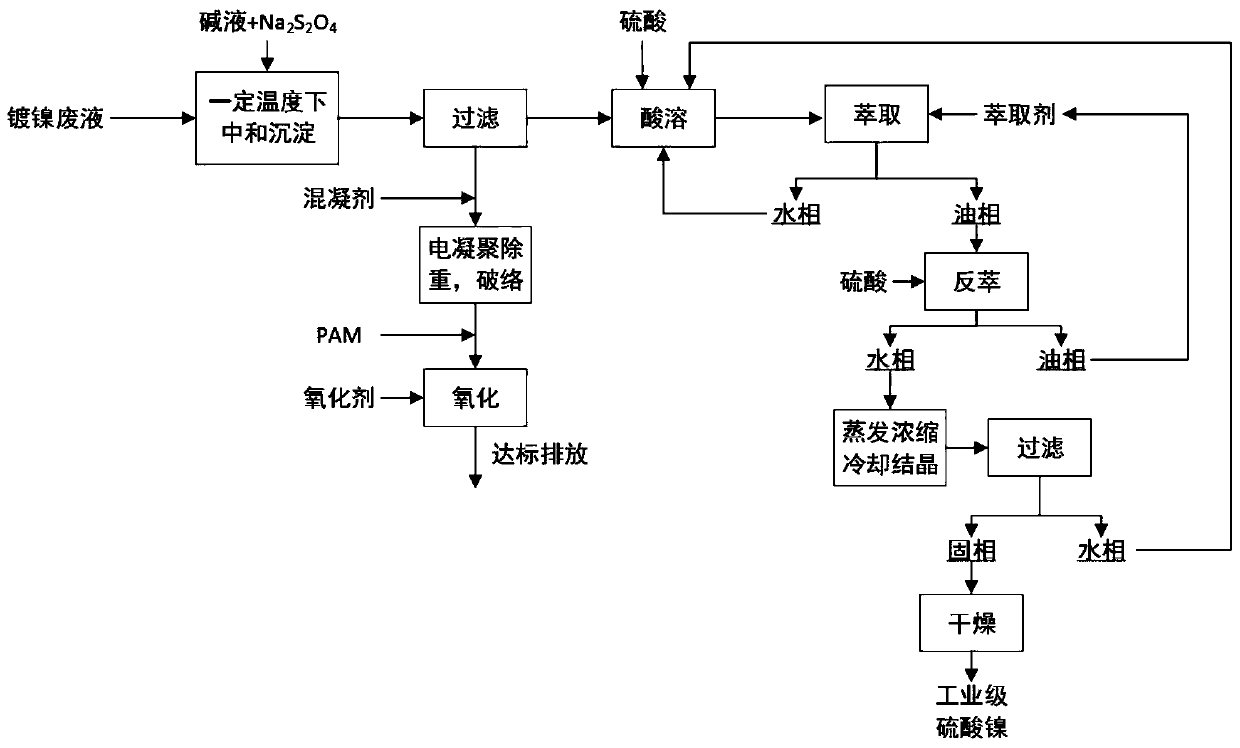

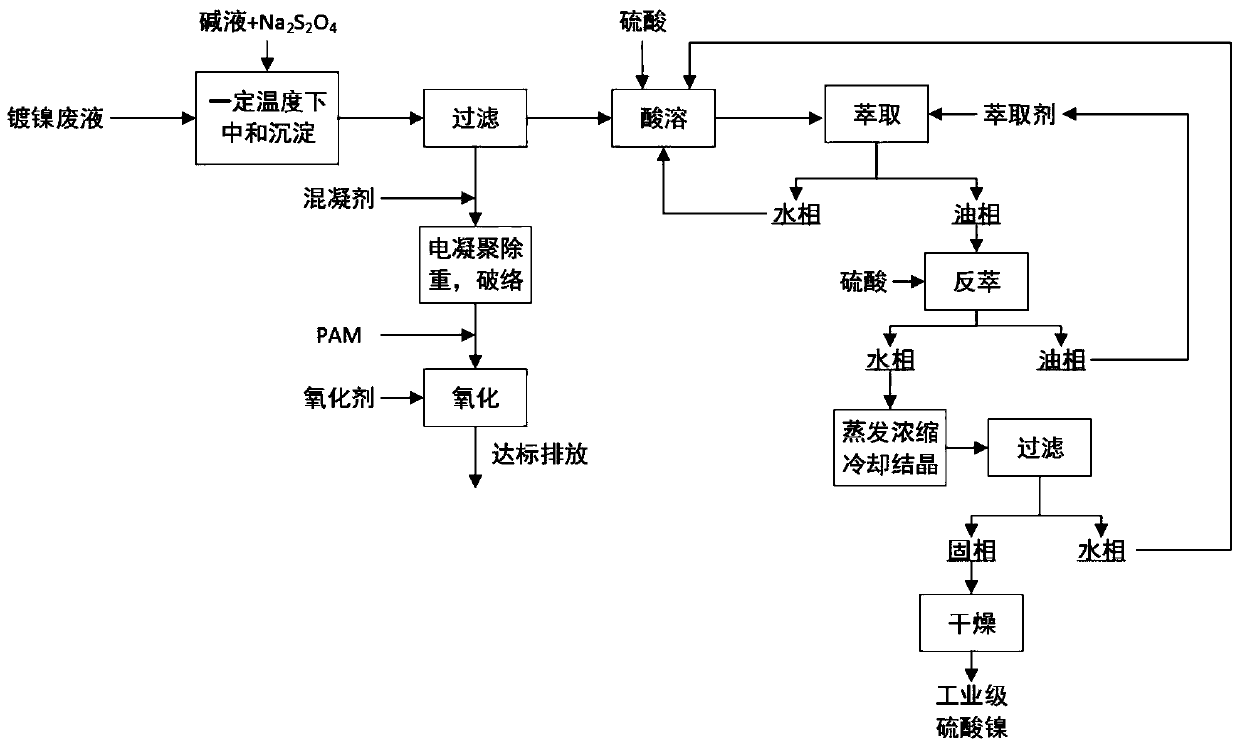

Method for recovering nickel sulfate from nickel electroplating waste liquid

A technology for electroplating nickel and nickel sulfate, applied in nickel sulfate, chemical instruments and methods, metallurgical wastewater treatment, etc., can solve the problems of high treatment cost, increase the difficulty of recovery, inability to handle, etc., and achieve high economic value and wide application range. , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Get 500mL certain enterprise electroplating nickel waste solution (nickel exists in the complex form), configure 150mL medicament (containing 15gNaOH and 5g NaOH 2 S 2 o 4 ). At the same time, nickel electroplating waste liquid and chemicals were added, heated and stirred in a water bath, the temperature was maintained at 80°C, and the reaction time was 2 hours. 500 mL of waste water consumed 100 mL of chemicals, and the stirring and heating were stopped. Vacuum filtration is then carried out for separation to obtain crystalline nickel hydroxide.

Embodiment 2

[0036] Get 500mL certain enterprise electroplating nickel waste liquid (same as in embodiment 1), add 10% sodium hydroxide solution, and add reduced iron powder simultaneously. Heat and stir in a water bath, maintain the temperature at 80°C, and react for 2 hours. 500mL of wastewater consumes 100mL of sodium hydroxide solution and 5g of reduced iron powder, and stop stirring and heating. Carry out vacuum filtration again and separate, obtain the mixture of the nickel hydroxide of crystal and a large amount of ferric hydroxide, introduce a large amount of impurity. In addition, the amount of hydroxide obtained in this example was significantly less than that obtained in Example 1, and nickel ions remained too much.

Embodiment 3

[0038] Get 500mL certain enterprise electroplating nickel waste liquid (same as in embodiment 1), add 10% sodium hydroxide solution, and add sodium thiosulfate simultaneously. Heat and stir in a water bath, maintain the temperature at 80 °C, and react for 2 hours. 500 mL of waste water consumes 100 mL of sodium hydroxide solution and 5 g of sodium thiosulfate, and stops stirring and heating. Carry out vacuum filtration again and separate, obtain the nickel hydroxide of less crystal. The amount of nickel hydroxide obtained in this embodiment is obviously less than that obtained in embodiment 1, and nickel ions remain too much.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com