Vacuum thin film filtration and microbial cultivation device

A technology of microbial culture and vacuum film, which is applied in the cultivation devices of tissue cells/viruses, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of vacuum pump inflow damage noise, manual repeated dumping, and increased artificial pollution, etc. Increase filtration speed, reduce labor intensity, and protect the effect of microporous membrane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] 1. Machine installation

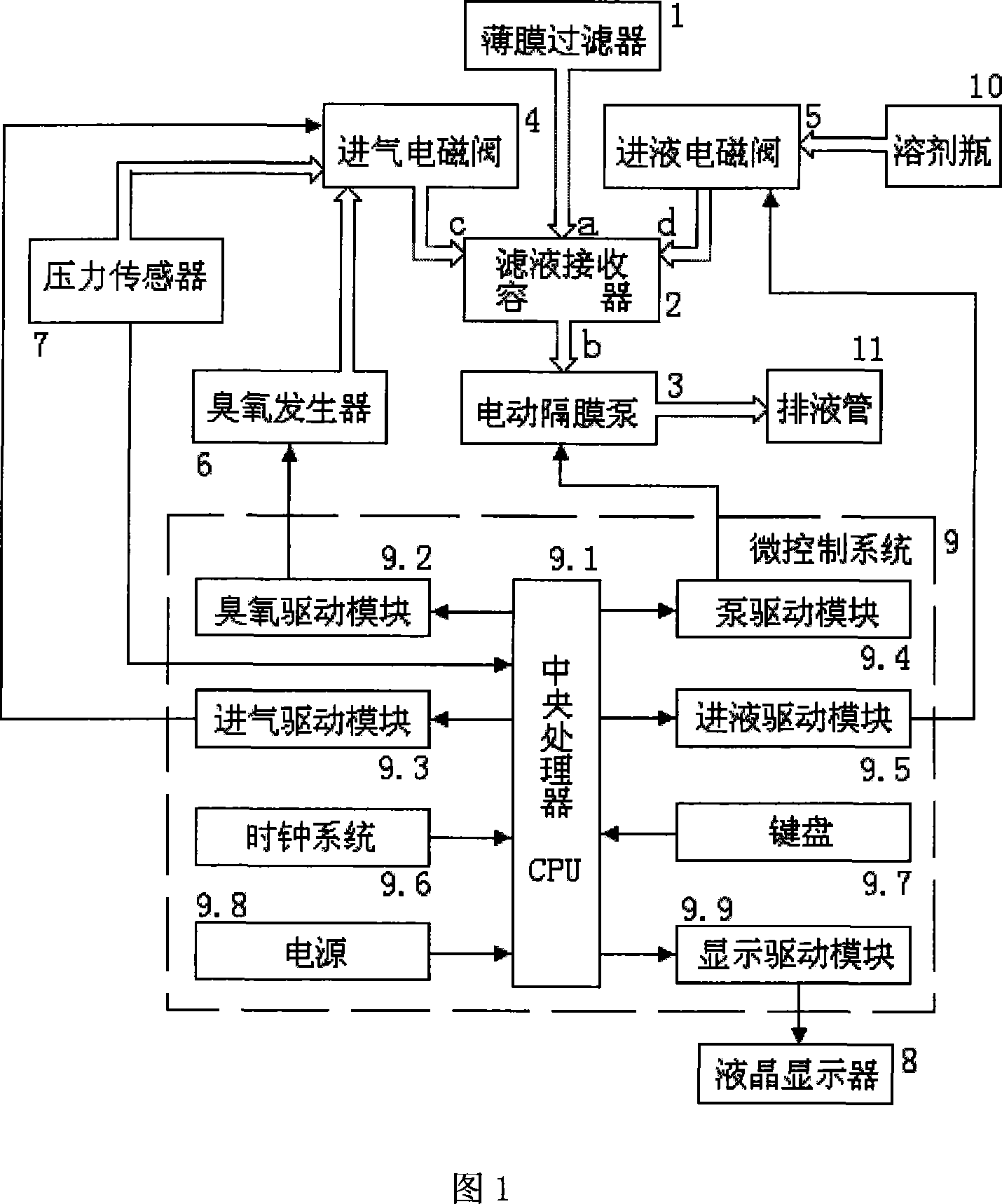

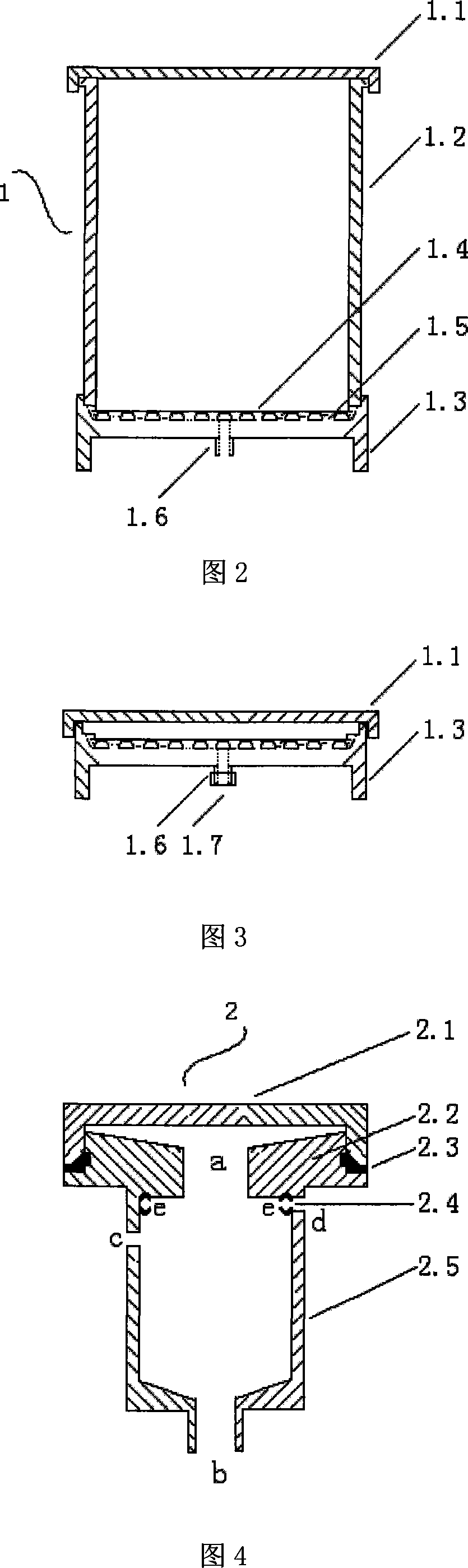

[0067] As shown in Figure 1, Figure 2, and Figure 4, the membrane filter (1), filtrate receiving container (2), electric diaphragm pump (3), and drain pipe (11) are connected in sequence to form a filtered liquid flow path for sample filtration;

[0068] As shown in Figure 1, the ozone generator (6) and the pressure sensor (7) are respectively connected to the filtrate receiving container (2) through the two air inlets of the air inlet solenoid valve (4) to form an ozone gas flow path, so that the filtrate receiving container (2) Obtain ozone when disinfection is required, and monitor the vacuum degree in the filtrate receiving container (2);

[0069] As shown in Figure 1, the solvent bottle (10), liquid inlet solenoid valve (5), and filtrate receiving container (2) are connected in sequence to form a cleaning liquid flow path, so that the filtrate receiving container (2) can obtain solvent when cleaning is required;

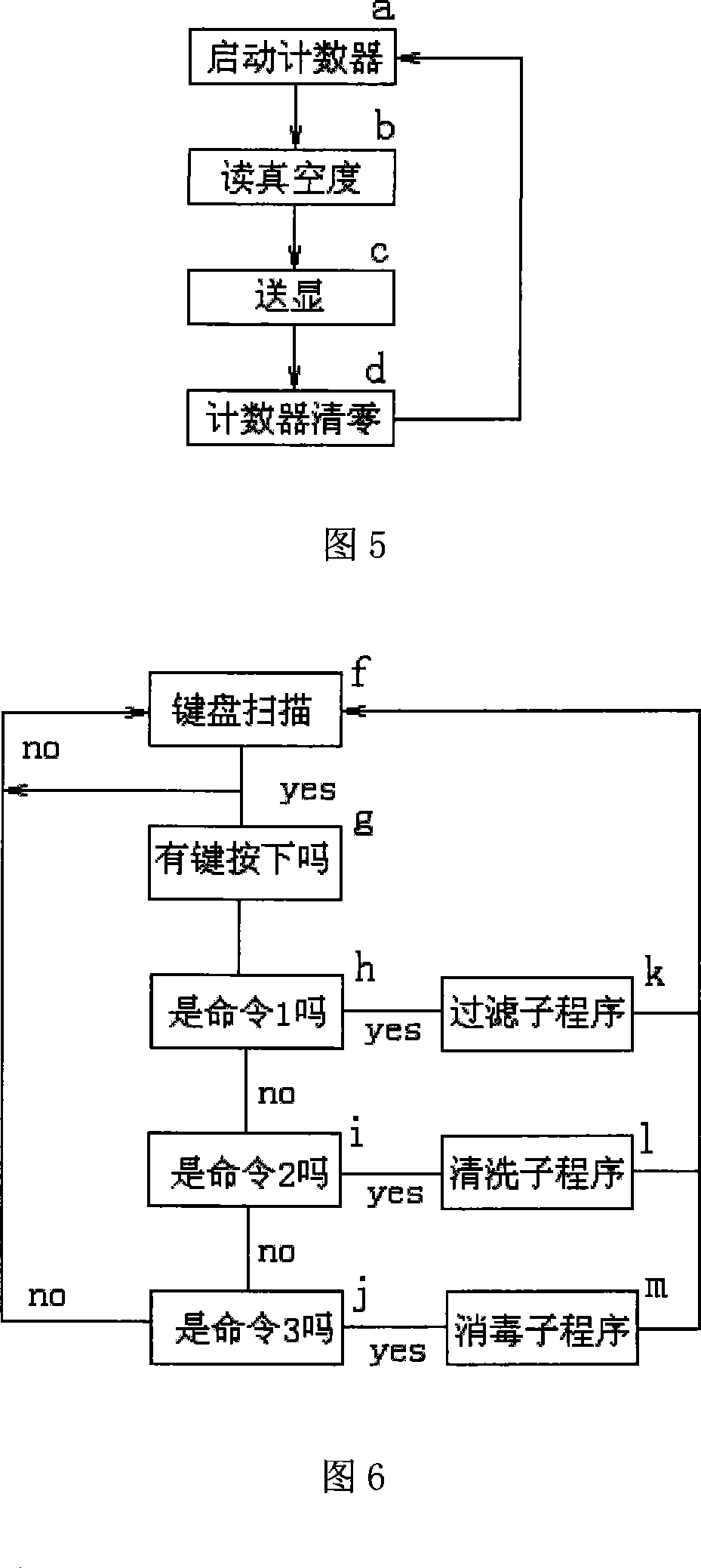

[0070] As shown in Fig. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com