Scale-removing and anti-scale agent for pipelines

An anti-scaling agent and pipeline technology, which is applied in the direction of scale removal and water softening, complex/solubilizing agent treatment, special treatment targets, etc., can solve the problems of poor corrosion resistance of pipelines, eutrophication of water bodies, and environmental pollution, etc., to achieve Low price, anti-corrosion, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

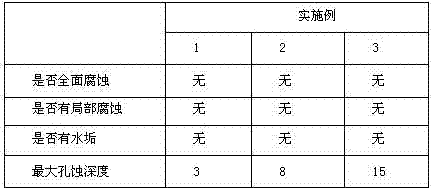

Embodiment 1

[0025] A descaling and antiscaling agent, which is made from the following raw materials in parts by weight: 4KG zinc chloride, 3KG isoascorbic acid, 1KG ammonium triacetate, 2KG sodium hydroxide, and 70KG water. The preparation method is: first heat the water to 40 ℃, then put it into the reaction kettle, then put in zinc chloride, isoascorbic acid, ammonium triacetate in proportion, then stir until it is uniform and transparent, then put in sodium hydroxide, and stir evenly.

Embodiment 2

[0027] A descaling and antiscaling agent, made from the following raw materials in parts by weight: 10KG zinc sulfate, 9KG sodium sulfite, 5KG disodium edetate, 9KG sodium hydroxide, and 92KG water. The preparation method is: first heat the water to 40°C, then put it into the reaction kettle, then put in zinc sulfate, sodium sulfite, and disodium edetate in proportion, then stir until it is uniform and transparent, then put in sodium hydroxide, and stir evenly.

Embodiment 3

[0029] A descaling and antiscaling agent, made from the following raw materials in parts by weight: 7KG sodium silicate, 6KG azodicarbonamide, 3KG sodium polyacrylate, 5.5KG potassium hydroxide, and 81KG water. Heat it to 40°C, then put it into the reaction kettle, then add sodium silicate, azodicarbonamide, and sodium polyacrylate in proportion, then stir until it is uniform and transparent, then add potassium hydroxide, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com