Purifying and filtering element for preventing breeding of microorganisms

A filter element and microbial technology, which is applied in water/sewage multi-stage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as affecting taste, water quality becomes salty, and microbial index increases, and achieves Improve the enthusiasm of use, prolong the service life, and improve the effect of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific content of the present invention will be further clarified below in conjunction with the accompanying drawings and embodiments.

[0023] Example:

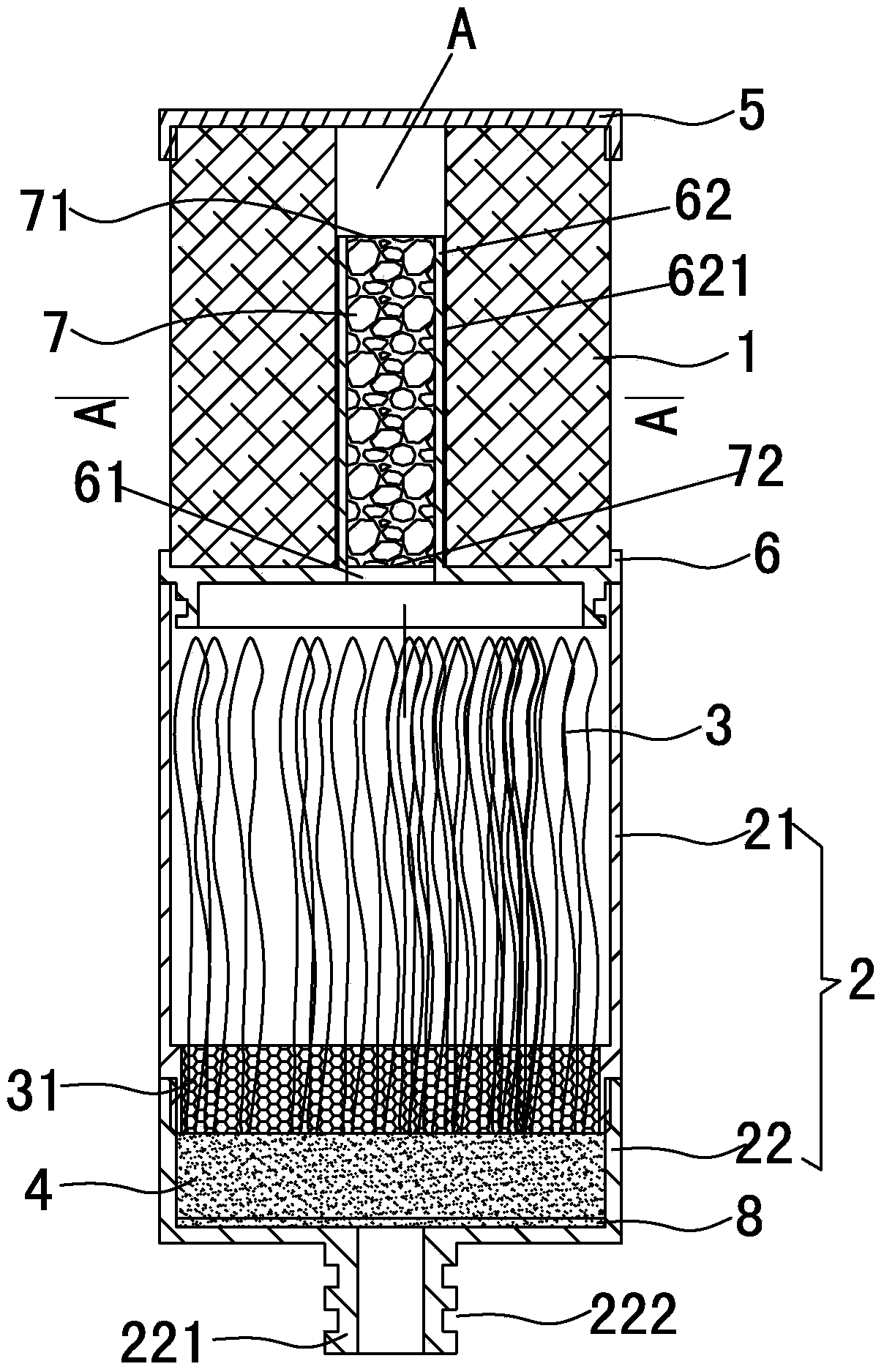

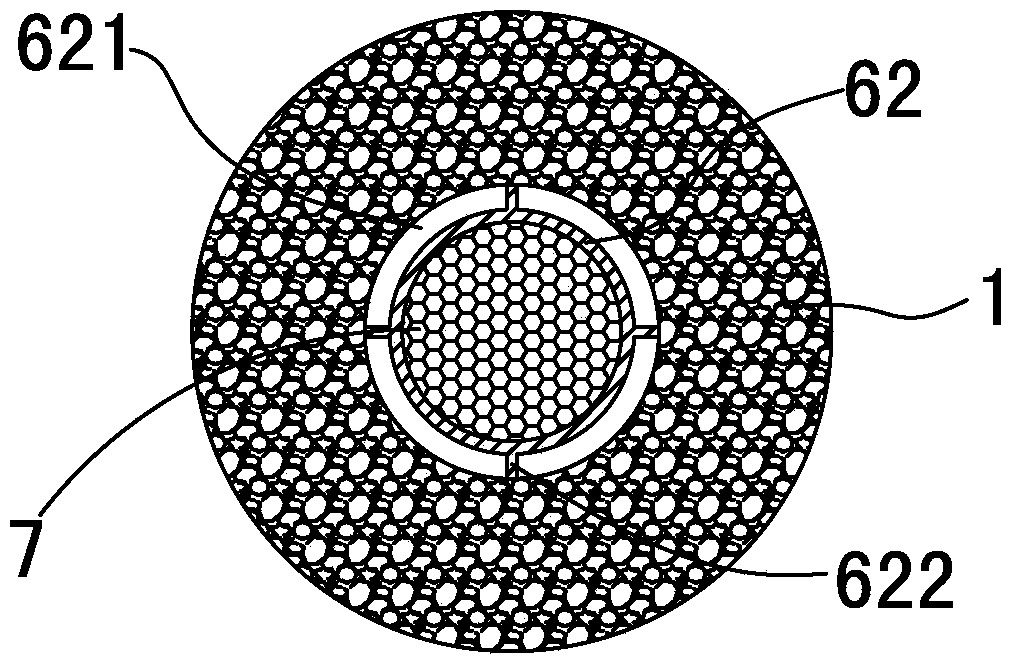

[0024] like Figure 1 to Figure 2 As shown, the embodiment of the present invention discloses a water purification filter element for preventing microbial growth, including an activated carbon fiber filter membrane cartridge 1 with a hollow filter cavity, an ultrafiltration membrane housing 2, an ultrafiltration membrane 3, an ultrafiltration membrane joint 31 and activated carbon Fiber filter sheet 4, the upper end surface of the activated carbon fiber filter membrane cartridge 1 is detachably provided with an upper sealing cover 5, the lower end surface of the activated carbon fiber filter membrane cartridge 1 is detachably provided with a lower end cover 6, and the middle part of the lower end cover 6 is It has a water outlet through hole 61, and the upper surface of the lower end cover 6 is located on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com