Galvanized steel sheet laser tailor welding method

A technology of galvanized steel sheet and laser tailor welding, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as welding defects, improve grain structure, reduce welding thermal stress, structure shape good looking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

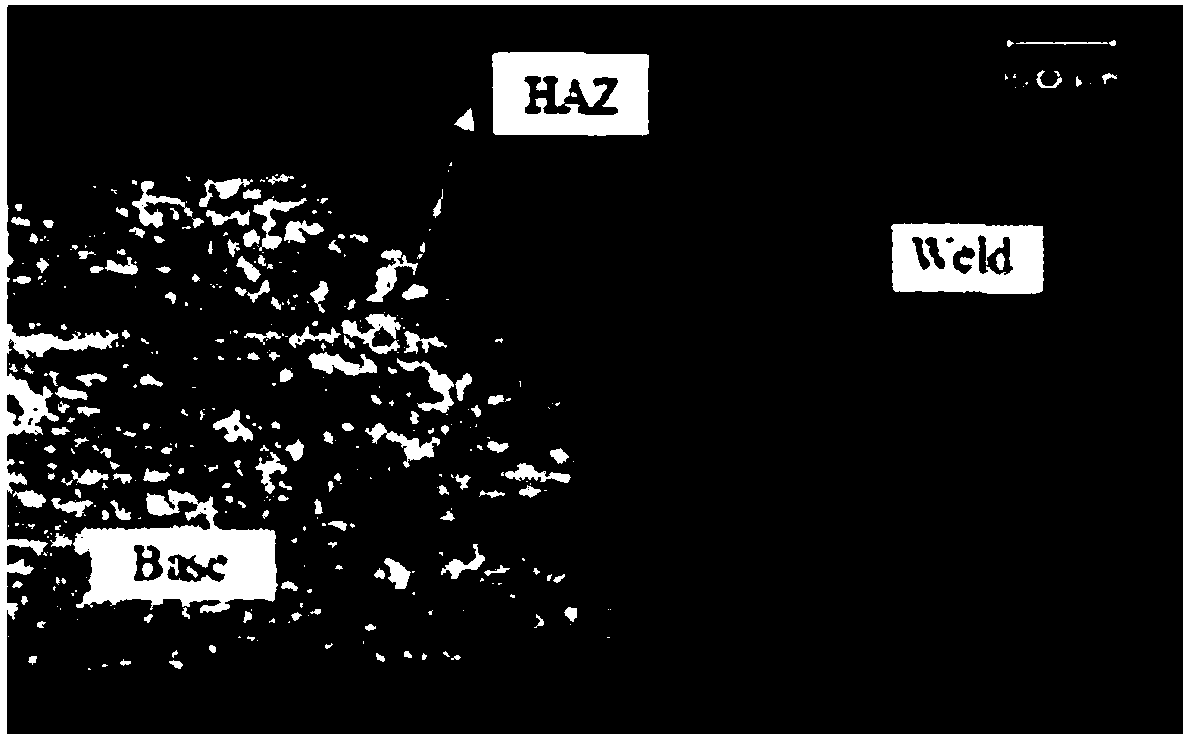

Image

Examples

Embodiment 1

[0025] A. Two galvanized steel sheets with a thickness of 1.2mm to be welded are to be wiped with anhydrous alcohol and acetone to remove oil stains and dirt on the surface of the galvanized steel sheets;

[0026] B. Splice the galvanized steel sheets and fix them with tooling tools;

[0027] C. Use laser beam to pre-weld galvanized steel plate. The laser beam power is 300W, the defocus is 0, the welding speed is 2.4m / min, and nitrogen is used as the side blowing gas for pre-welding;

[0028] D. Use laser beam to laser weld galvanized steel plate. The laser beam power is 1000W, the defocus is -0.5mm, the welding speed is 1.8m / min, and nitrogen is used as the shielding gas during the welding process;

[0029] E. After welding, put the galvanized steel sheet after tailor welding in a heat treatment furnace at 150°C for heat treatment, and cool it in the air to room temperature after holding time for 3 hours.

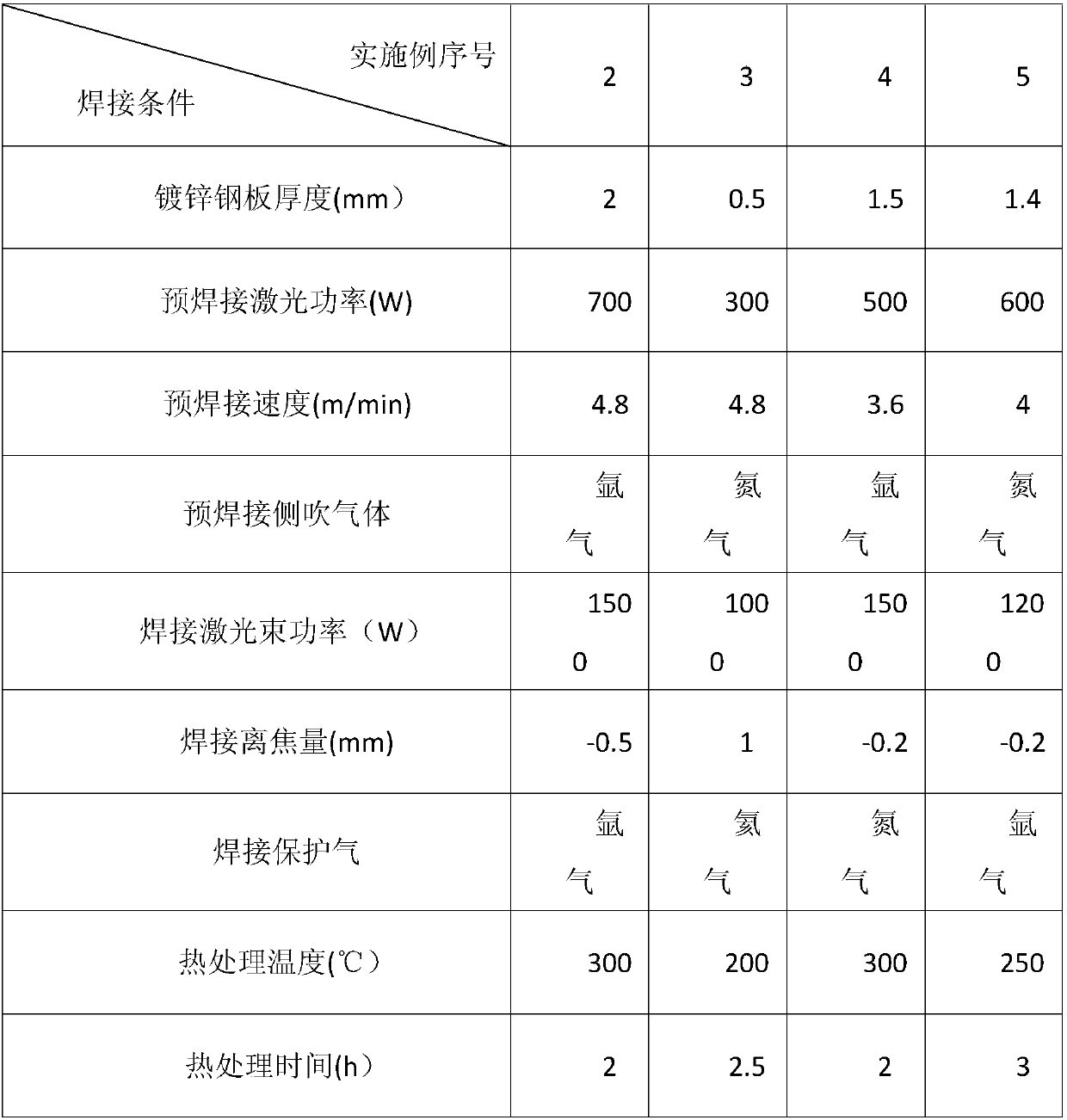

[0030] The operation steps of embodiment 2~5 are identical with embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com