Method and device for producing dichlorotoluene by tower-type continuous chlorination

A technology of dichlorotoluene and o-chlorotoluene, which is applied in chemical instruments and methods, organic chemistry, preparation of halogenated hydrocarbons, etc., can solve the problems of high energy consumption and material consumption, backward technology, etc., and achieve reasonable technology, high product yield, The effect of high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

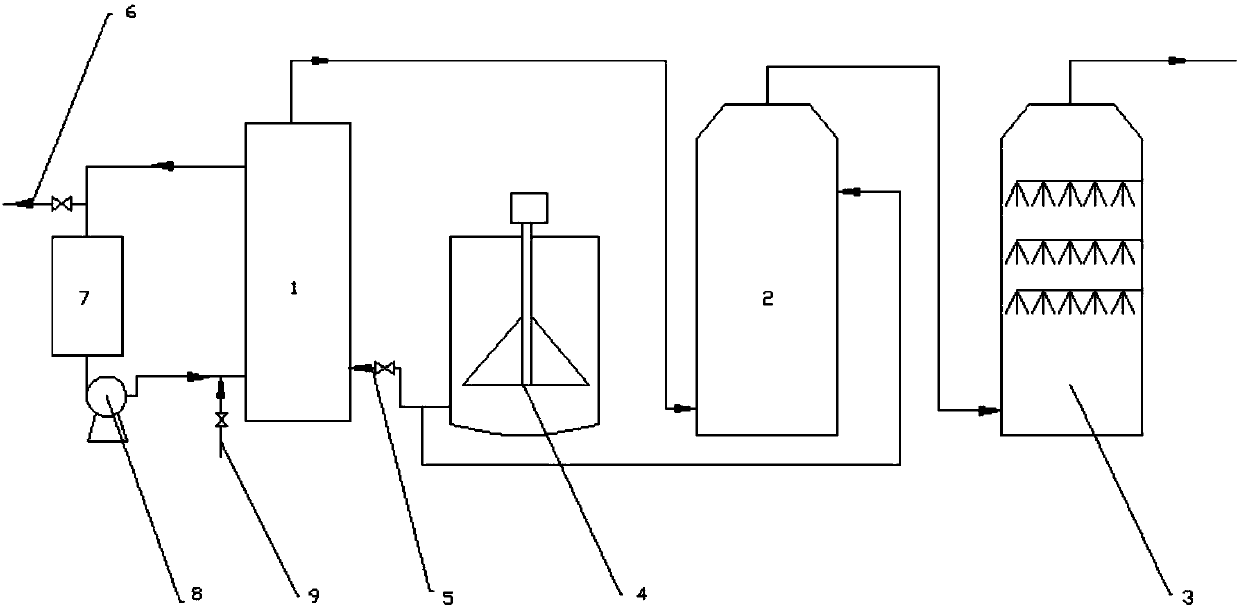

[0017] A tower-type continuous chlorination device for producing dichlorotoluene, comprising a tower reactor 1 for continuous chlorination reaction, an absorption tower 2 for removing chlorine in tail gas, and a spray tower 3 for removing chlorine in tail gas And for forming the configuration tank 4 of the configuration liquid, the bottom of the tower reactor is provided with a configuration liquid feed pipe 5, and the configuration liquid feed pipe 5 is connected to the configuration tank 4, and on the configuration liquid feed pipe A metering pump is provided; the upper part of the tower reactor is provided with a chlorinated liquid outlet, and the chlorinated liquid outlet is connected with the chlorinated liquid output pipe, and the chlorinated liquid output pipe is connected with the chlorinated liquid The liquid external circulation pipe is connected, the external circulation pipe of the chlorinated liquid is connected with the bottom of the tower reactor, the output pipe...

Embodiment 2

[0020] Put 55kg of o-chlorotoluene and 203 g of ferric chloride (catalyst) into the preparation tank and stir for half an hour to form a configuration liquid, then use a metering pump to send the configuration liquid into the tower reaction tower through the feed pipe, and then open Circulation pump to circulate, open the chlorine gas flow regulating valve to pass chlorine, the chlorine gas flow rate is 0.3m3 / h, when the reaction temperature reaches 20°C, turn on the heat exchanger to circulate cooling water to cool the chlorinated liquid, properly adjust the chlorine gas flow rate and the cooling water of the cooler The opening degree controls the reaction temperature at 25-40°C, and the reaction time is about 11 hours. The total mass of the reaction intermediate liquid is detected to be 62kg, and the composition is shown in Table 1 below:

[0021] Table 1

[0022] Element

[0023] After calculation, the conversion rate of the raw material o-chlorotoluene reaches 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com