Environment-friendly and flame-retarding polydicyclopentadiene material and preparation method thereof

A polydicyclopentadiene, environmentally friendly technology, applied in the field of environmentally friendly flame-retardant polydicyclopentadiene materials and their preparation, can solve the problems affecting the mechanical and physical and chemical properties of polydicyclopentadiene, mechanical performance damage, safety hazards, etc. , to achieve the effects of close relationship, enhanced interface performance, and accelerated preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

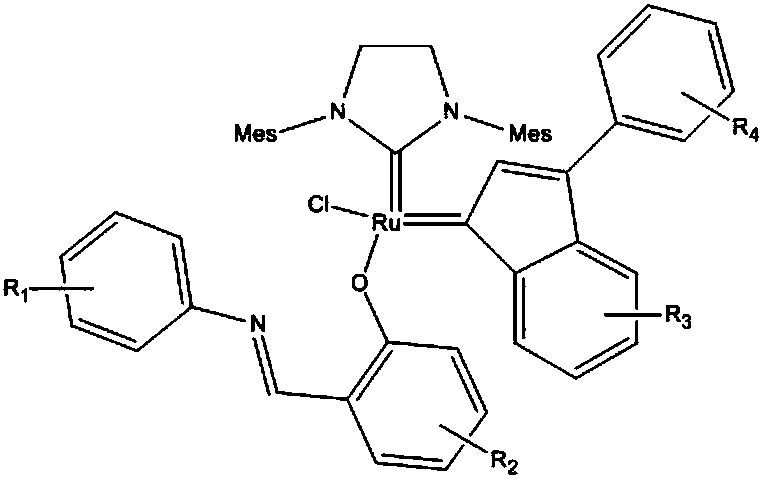

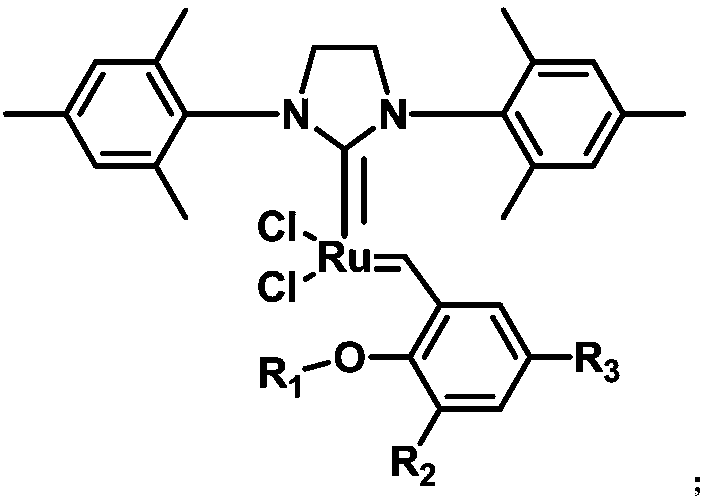

Method used

Image

Examples

Embodiment 1

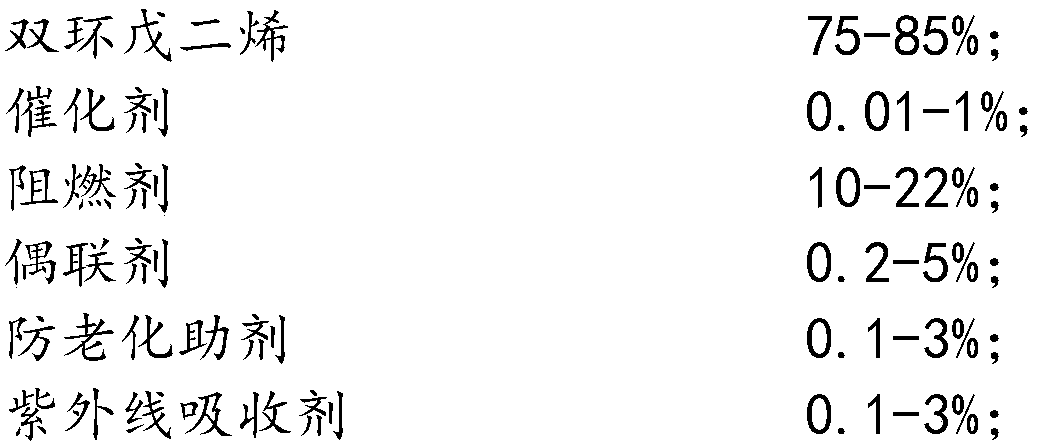

[0049] The polydicyclopentadiene material 1# of the present embodiment is made of the following components by weight percentage:

[0050]

[0051] Prepare environment-friendly flame-retardant polydicyclopentadiene material 1# according to the following steps:

[0052] 1) Weigh 50% wt of dicyclopentadiene, aluminum hydroxide modified by a titanate coupling agent, Clariant’s Exolit series phosphate flame retardant, and kh550, and fully mix it as a dosage A;

[0053] 2) The remaining dicyclopentadiene, catalyst, 2,6-di-tert-butyl-4-methylphenol, tris(2,4-di-tert-butylphenyl) phosphite, UV-327, UV- 1157 is fully mixed to make dosage B;

[0054] 3) Add the mixed ingredients A and B to the two silos of the injection molding machine respectively, and adjust the rate ratio of suction to 4.3:1;

[0055] 4) After starting the injection molding machine, suck the two kinds of materials A and B into the injection gun head at the same time and mix them;

[0056] 5) Inject the mixed ma...

Embodiment 2

[0059] The polydicyclopentadiene material 2# of the present embodiment is made of the following components by weight percentage:

[0060]

[0061] Prepare environment-friendly flame-retardant polydicyclopentadiene material 2# according to the following steps:

[0062] 1) Weigh 50%wt of dicyclopentadiene, aluminum hydroxide modified by silane coupling agent, Clariant's Exolit series phosphate flame retardant, TMC-201 and fully mix it as material A;

[0063] 2) Fully mix the remaining dicyclopentadiene, catalyst, bis(3,5-di-tert-butyl-4-hydroxyphenyl) sulfide, UV-1164, UV-1157 to prepare material B;

[0064] 3) Add the mixed ingredients A and B to the two silos of the injection molding machine respectively, and adjust the rate ratio of suction to 4.3:1;

[0065] 4) After starting the injection molding machine, suck the two kinds of materials A and B into the injection gun head at the same time and mix them;

[0066] 5) Inject the mixed material into the mold (mold temperatu...

Embodiment 3

[0069] The polydicyclopentadiene material 3# of the present embodiment is made of the following components by weight percentage:

[0070]

[0071] Prepare environment-friendly flame-retardant polydicyclopentadiene material 3# according to the following steps:

[0072] 1) Weigh 40%wt of dicyclopentadiene, aluminum hydroxide modified by silane coupling agent, TMC-201, heat to 45°C and fully mix as dosage A;

[0073] 2) Weigh 40% wt of dicyclopentadiene, Clariant's Exolit series of phosphate flame retardants, and kh550 and mix them fully to prepare material B;

[0074] 3) Fully mix the remaining dicyclopentadiene, catalyst and other remaining components to make dosage C;

[0075] 4) After mixing material A and material B while they are hot, add material C and mix evenly and inject it into the mold;

[0076] 5) When the mold temperature is 50-80°C, hold the pressure for 1-2 minutes;

[0077] 6) Open the mold and remove the mold to obtain an environmentally friendly flame-ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com