Thermochromic polypropylene composition and its preparation method and use

A technology of polypropylene composition and temperature-sensitive discoloration, which is applied in the field of plastic modification to achieve good heat resistance, excellent long-term heat resistance, and little heat influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-11

[0031] Preparation of embodiment 1-11 thermochromic microcapsules:

[0032] Addition reaction of formaldehyde and melamine with a molar ratio of 2.5 / 1~3 / 1 at a pH of 7.5~8.5 to obtain a methylol melamine prepolymer, and then disperse the triphenylmethane metal complex at 0.2-1.0 In the sodium dodecylsulfonate aqueous solution with wt% concentration, finally add the methylol melamine prepolymer to the above solution, and adjust the solution to pH 5.5~6.5 to obtain a microcapsule emulsion, react at 80-90°C for 3h , after washing, suction filtration, and drying, obtain thermosensitive color-changing microcapsules; wherein, the mol ratio of formaldehyde and melamine in Example 1-2 is 2.5 / 1, and the mol ratio of formaldehyde and melamine in Example 3-5 is 2.75 / 1 , The mol ratio of formaldehyde and melamine is 3 / 1 among the embodiment 6-11.

[0033] The concentration of the above-mentioned sodium dodecylsulfonate aqueous solution is 0.8wt%, and the product is a thermochromic microc...

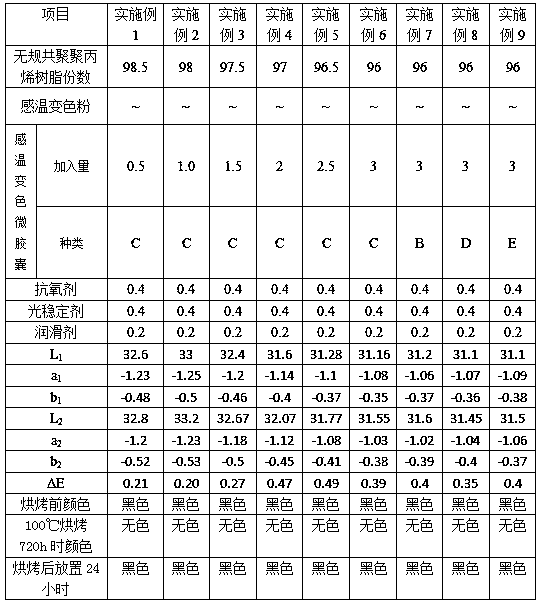

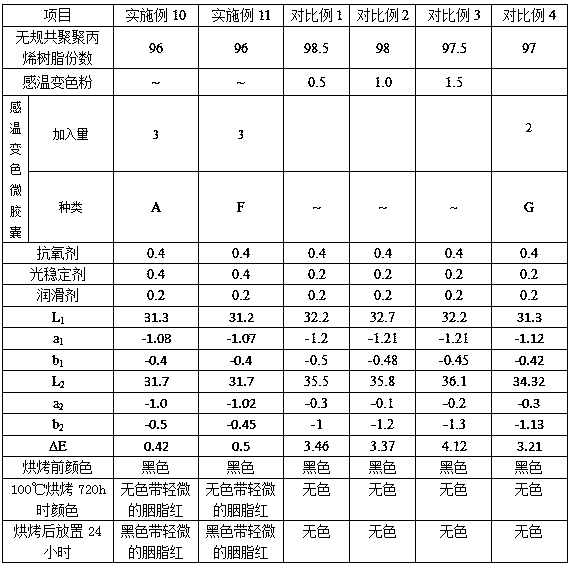

Embodiment 1-11 and comparative example 4

[0041] Preparation of the polypropylene composition of embodiment 1-11 and comparative example 4 temperature-sensitive discoloration:

[0042] According to the formula in Table 1, random copolymerized polypropylene resin, antioxidant, light stabilizer, lubricant and thermochromic microcapsules were mixed and then added to a twin-screw extruder for melt kneading. The melt kneading temperature was 170 ~190°C, extruded and granulated to obtain the polypropylene composition, and then injection molded the composition into a color plate for testing its color changing performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com