Confocal auto-collimation decentration and curvature radius measurement method and device

A technology of curvature radius and measurement method, which is applied in the direction of measuring device, optical device, geometric characteristics/aberration measurement, etc., can solve the problems of inability to accurately locate the lens, poor axial positioning accuracy, and inability to tomographically locate, etc., to achieve The effect of improving measurement efficiency, reducing volume, and simplifying the measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

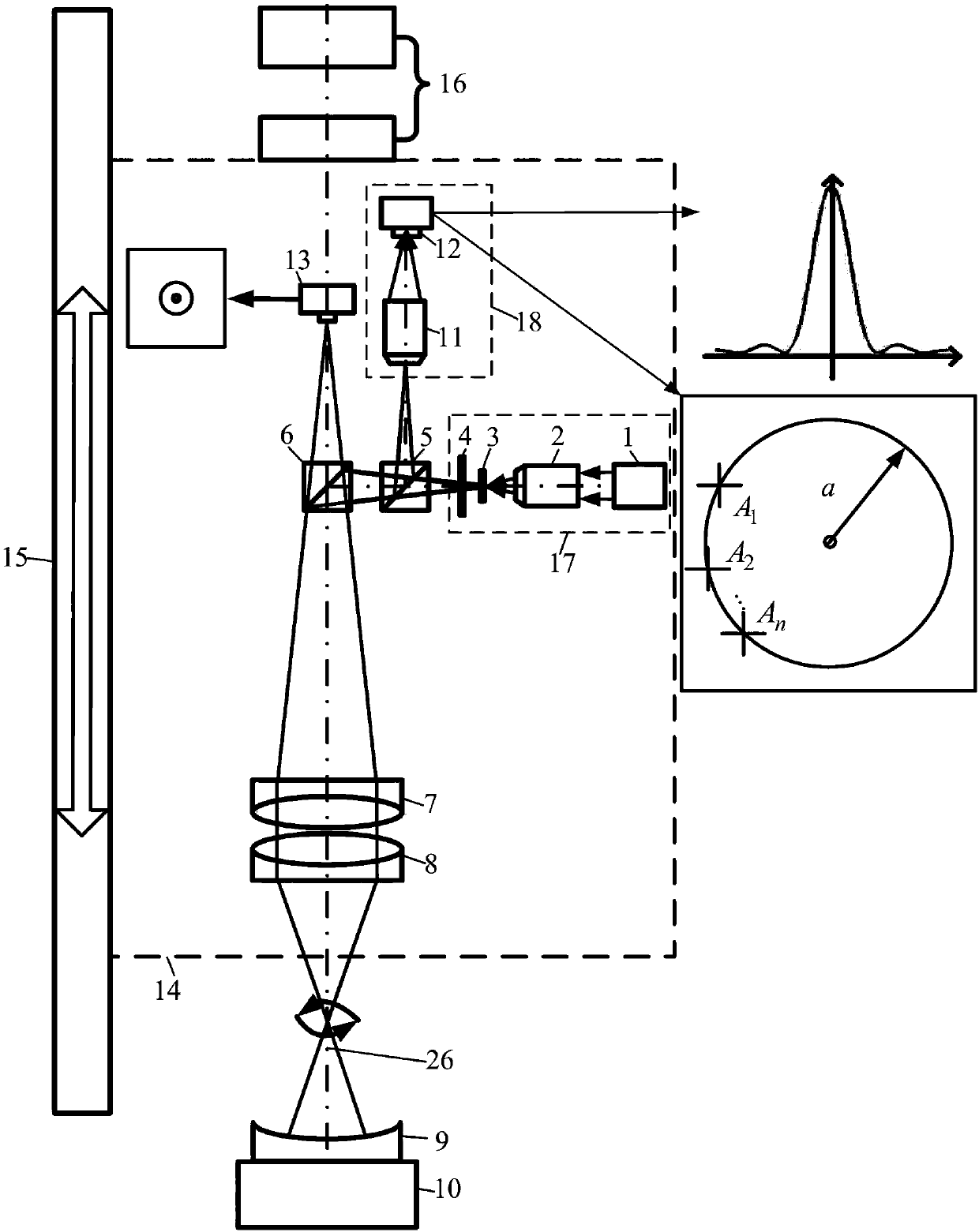

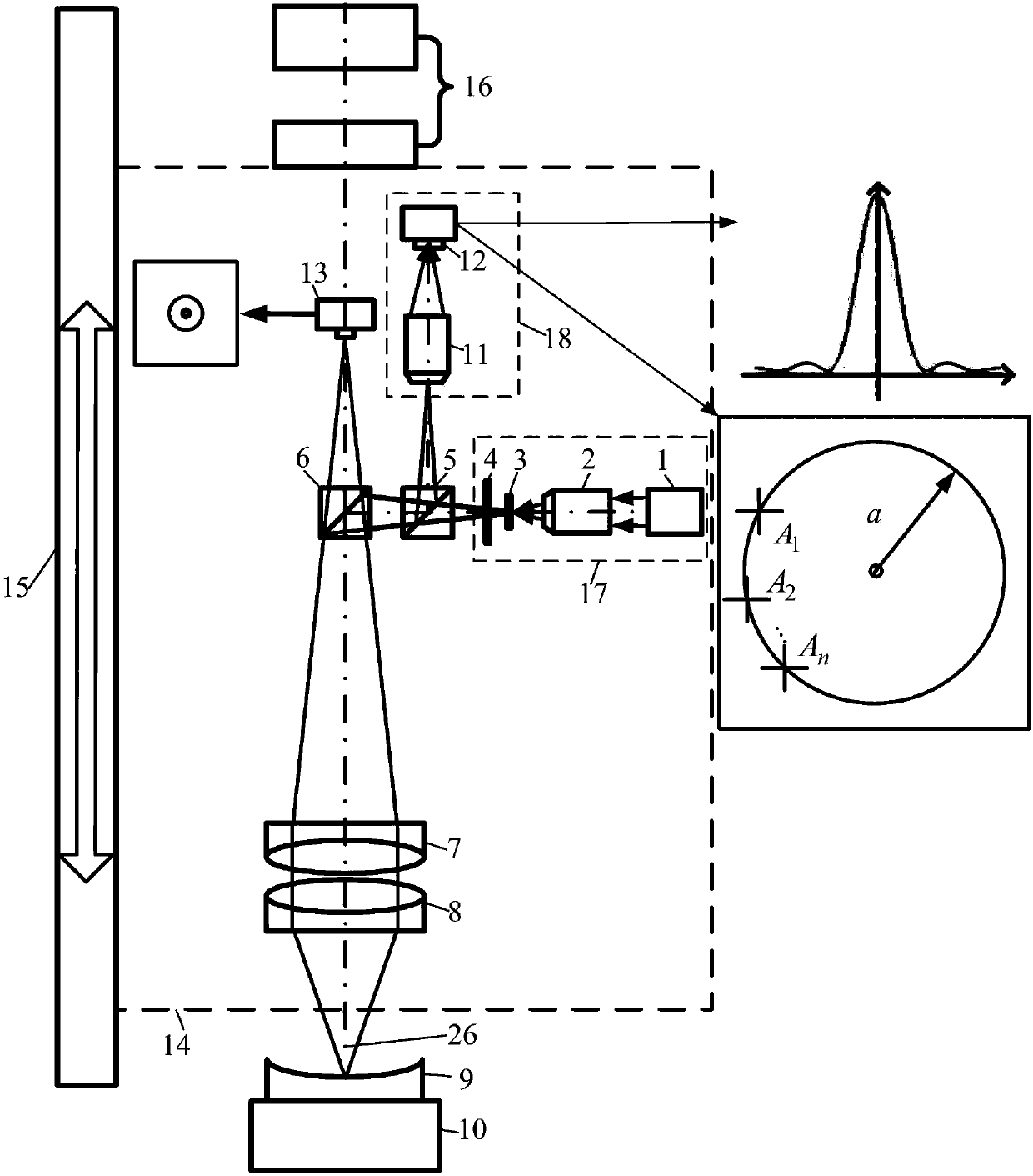

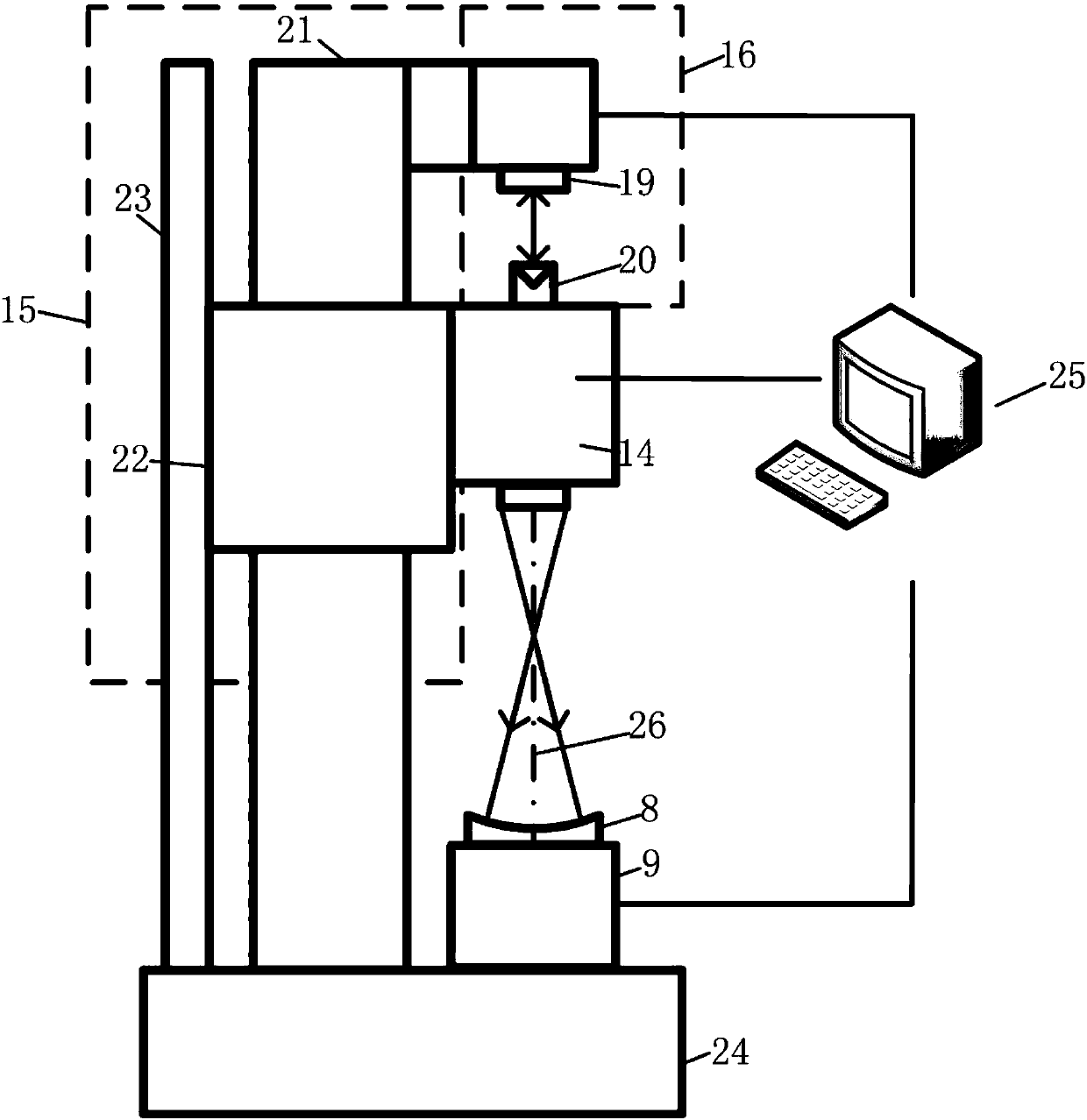

[0045] Such as figure 1 , figure 2 and image 3 As shown, the confocal autocollimation center deviation and curvature radius measurement method, the measurement steps are:

[0046] Before the measurement, first adjust the measuring optical axis 26 to coincide with the axis of the air bearing rotating shaft 10, the measuring optical axis 26 to be parallel to the air bearing guide rail 21, and the optical axis of the length measuring interferometer 19 to coincide with the measuring optical axis 26. During detection, place a flat mirror as the measured mirror 9 at the center of the air-floating shaft 10, start the driving screw 23 to drive the slider 22 to focus the measuring light cone emitted by the measuring host 14 on the surface of the flat mirror; start the air-floating shaft 10 to drive the flat mirror Rotate, observe the paths of the light spots on the first detector 13 and the confocal detector 18, and adjust the axial plane of the air bearing shaft 10, so that the li...

Embodiment 2

[0055] Such as Figure 4 As shown, the confocal autocollimation center deviation and radius of curvature measurement method can also measure the curvature radius and center deviation of the convex lens, and the measurement steps are the same as in embodiment 1:

[0056] First, the axis of the air-floating rotating shaft 10 is adjusted to coincide with the optical axis 26 of the measuring host 14. The measured mirror 9 is a convex lens placed at the center of the air-floating rotating shaft 10, and the measuring host 14 is moved along the direction of the measuring optical axis 26 to make the measuring light cone Focus on the vertex and the center of the sphere of the mirror under test 9 respectively, and the length measurement interferometer 19 records the vertex z 1 and center z 2 , the calculated radius of curvature r=z 1 -z 2 ; at center z 2 At the position, the air-floating rotating shaft 10 is started to drive the measured mirror 9 to rotate, the radius of the fitting...

Embodiment 3

[0058] Such as Figure 5 As shown, the confocal autocollimation center deviation and curvature radius measurement method can also measure the curvature radius and center deviation of the lens group, and obtain the best fitting optical axis. The measurement steps are:

[0059] Step 1. The lens group is used as the measured mirror 9, placed in the center of the air-floating shaft 10, the bottom surface coincides with the axial surface of the air-floating shaft 10, the screw 23 drives the slider 22 to move along the guide rail 21, so that the measuring light cone is focused on the first The spherical center of a lens, detect the eccentricity of the first lens χ 1 =a 1 / (2β);

[0060] Step 2, move the measuring host 14, focus the measuring light cone to the center of the second lens, detect the eccentricity between the second lens and the axis of the lens group, and take into account the eccentricity and spacing introduced by the first lens during calculation Magnification to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com