Hydrate mining well mechanical screen pipe erosion evaluation simulation system and simulation testing method thereof

A simulation system and a technology of mechanical screen, applied in the field of simulation system, can solve the problems such as the impact of the anti-erosion performance of the screen tube on the sand retaining effect, the impact of the three-phase flow of the screen tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

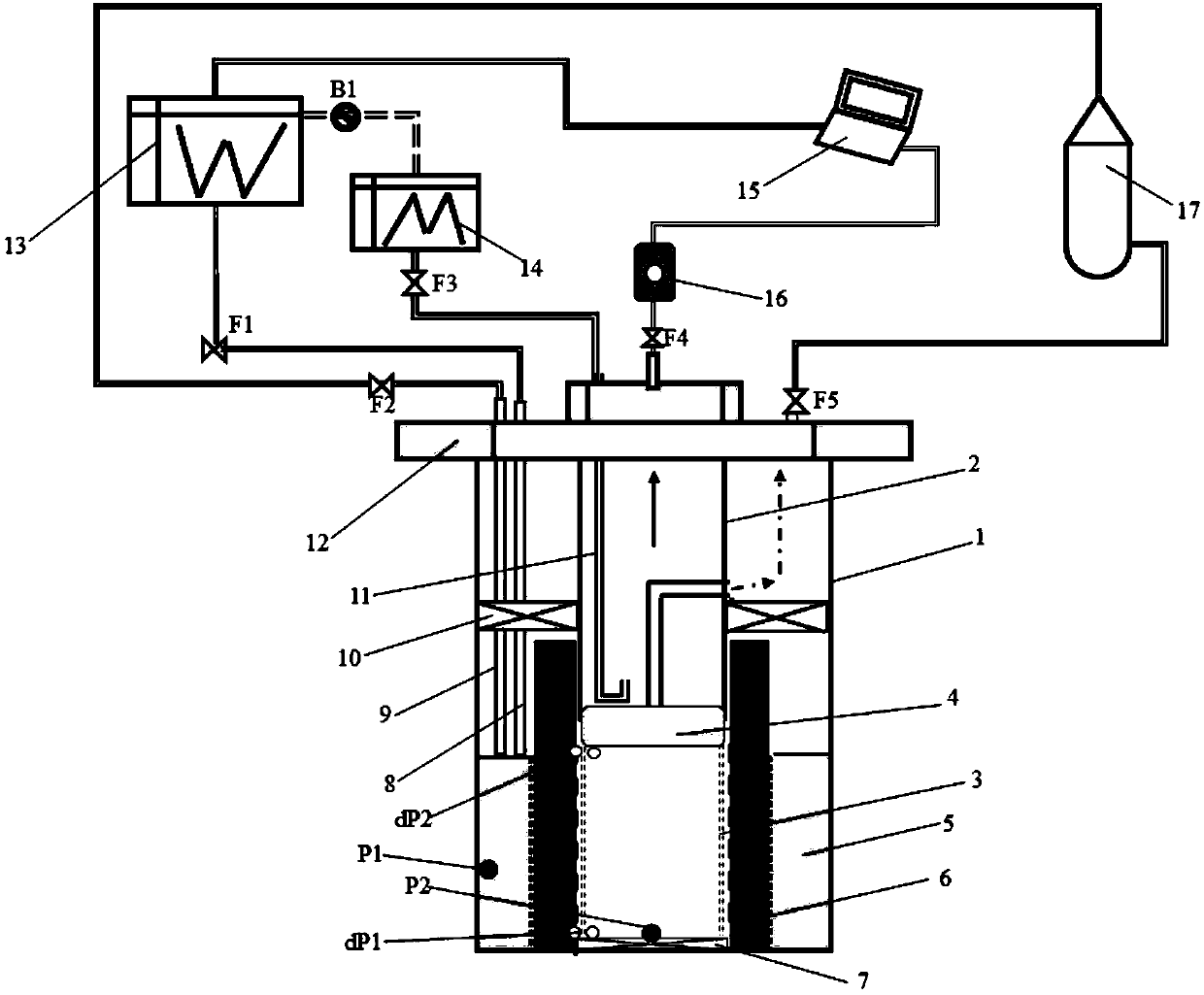

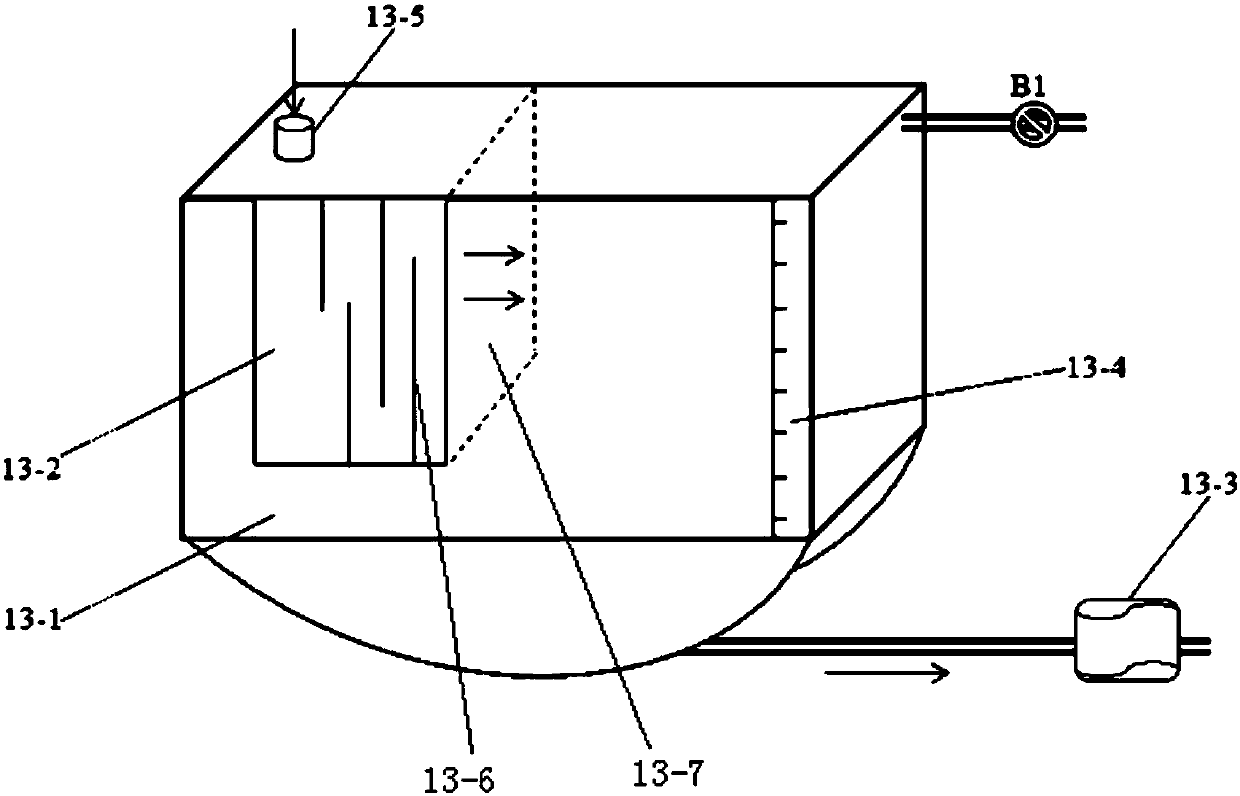

[0044] Example 1. The mechanical screen erosion evaluation simulation system for hydrate production wells has a 1:1 correspondence with the actual construction tools. During the simulation experiment, the system forms a closed high-pressure circulation system with a simulated maximum pressure of 15 MPa, which meets the actual conditions. Simulation of gas hydrate reservoir pressure conditions, such as figure 1 As shown, including downhole subsystem, surface subsystem and data acquisition and analysis subsystem;

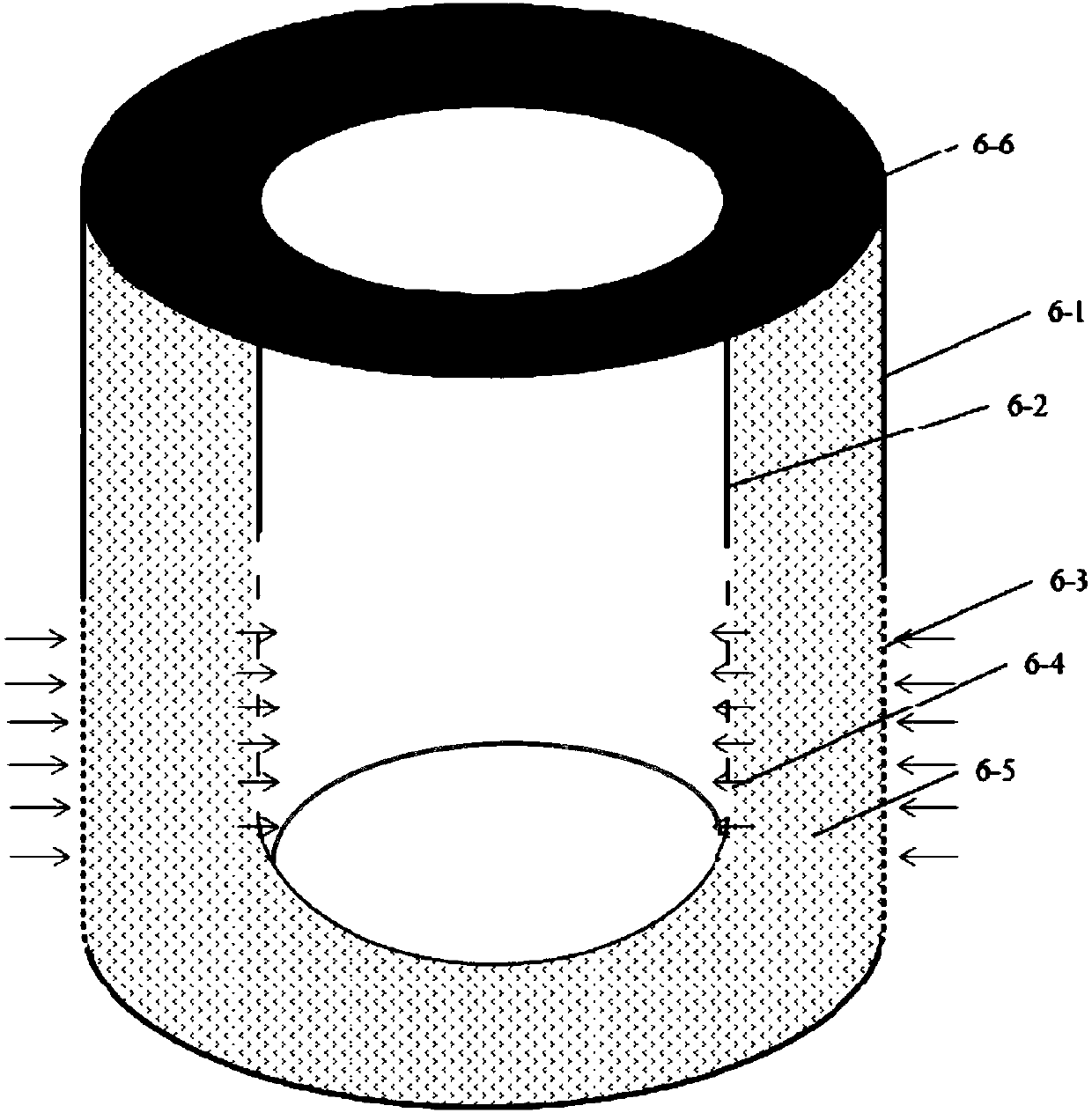

[0045] The basic structure of the downhole subsystem is a test well with a depth of 200m, which can meet the full-scale simulation of the actual gas hydrate production well screen conditions, including the simulated wellbore 1 and the simulated tubing 2 set in the simulated wellbore 1, Mechanical screen pipe 3, mechanical screen pipe plugging device 7, oil pipe crossing packer 10, gas-liquid mixer 5, pre-set sand supply device 6, gas separator 4, gas injection pipelin...

Embodiment 2

[0053] Embodiment 2, based on the simulation system described above, the present invention also proposes a simulation test method for evaluating the erosion of mechanical screen pipes in hydrate production wells, including the following steps:

[0054] A. Connect the surface subsystem, downhole subsystem and data acquisition and analysis subsystem, pressurize (15MPa) inside the system through the simulated water injection tank, and keep it for a period of time to verify the tightness of the system;

[0055] B. Carry out mechanical screen pipe working condition simulation, including:

[0056] B1. Start the simulation water injection tank and gas supply recovery tank group, control a certain gas-liquid ratio and gas-liquid injection flow rate, and inject liquid and gas into the gas-liquid mixer from the liquid injection pipeline and gas injection pipeline respectively;

[0057] B2. The gas-liquid mixer fully mixes the gas and liquid, and simulates the erosion process of the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com