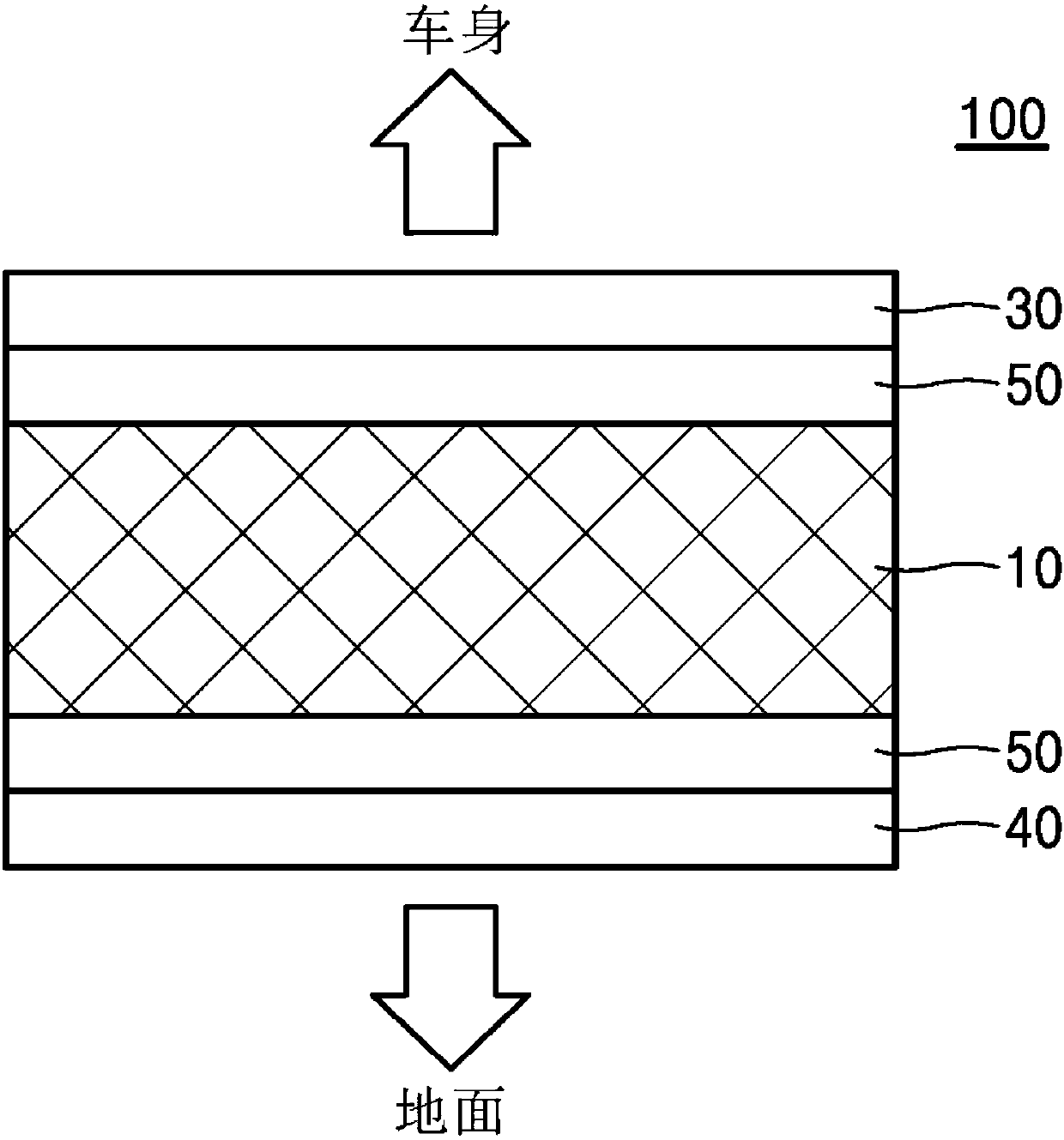

Vehicle underbody cover and method for manufacturing same

A body and bottom cover technology, applied in the field of vehicle body bottom cover and its manufacturing, can solve the problems of inability to effectively block the impact sound, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

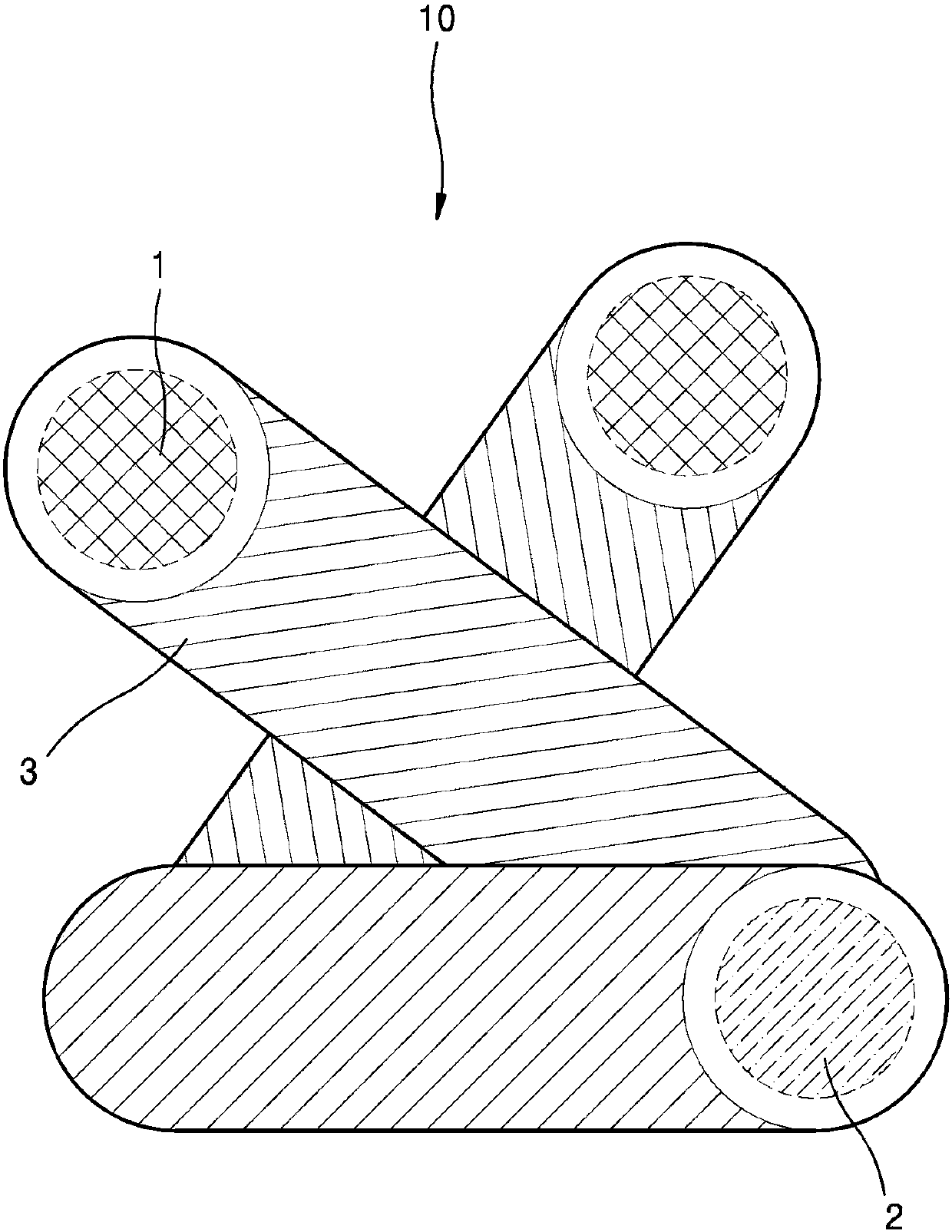

Embodiment 1

[0143] As the binary polymer fiber, the following fibers were prepared: the polyester core and the low-melting point polyester sheath had a weight ratio of 50:50, a length of 5 mm in order to ensure water dispersibility, and 4 denier (about 20μm cross-sectional diameter) thickness. Glass fibers having a cross-sectional diameter of 13 μm and coated in a manner suitable for water-based dispersion were cut to a length of 13 mm to prepare glass fibers. After blending 40 parts by weight of the above-mentioned glass fiber and 60 parts by weight of the above-mentioned binary polymer fiber, it was stirred in an aqueous solution adjusted to pH 2 with hydrochloric acid for 1 hour. In this case, the total fiber content of glass fibers and binary polymer fibers was adjusted to 2 g per 1 L of water. On the aqueous slurry that has been subjected to the stirring process in the manner described above, a wet papermaking process was performed in a headbox by vacuum suction to form a web. Afte...

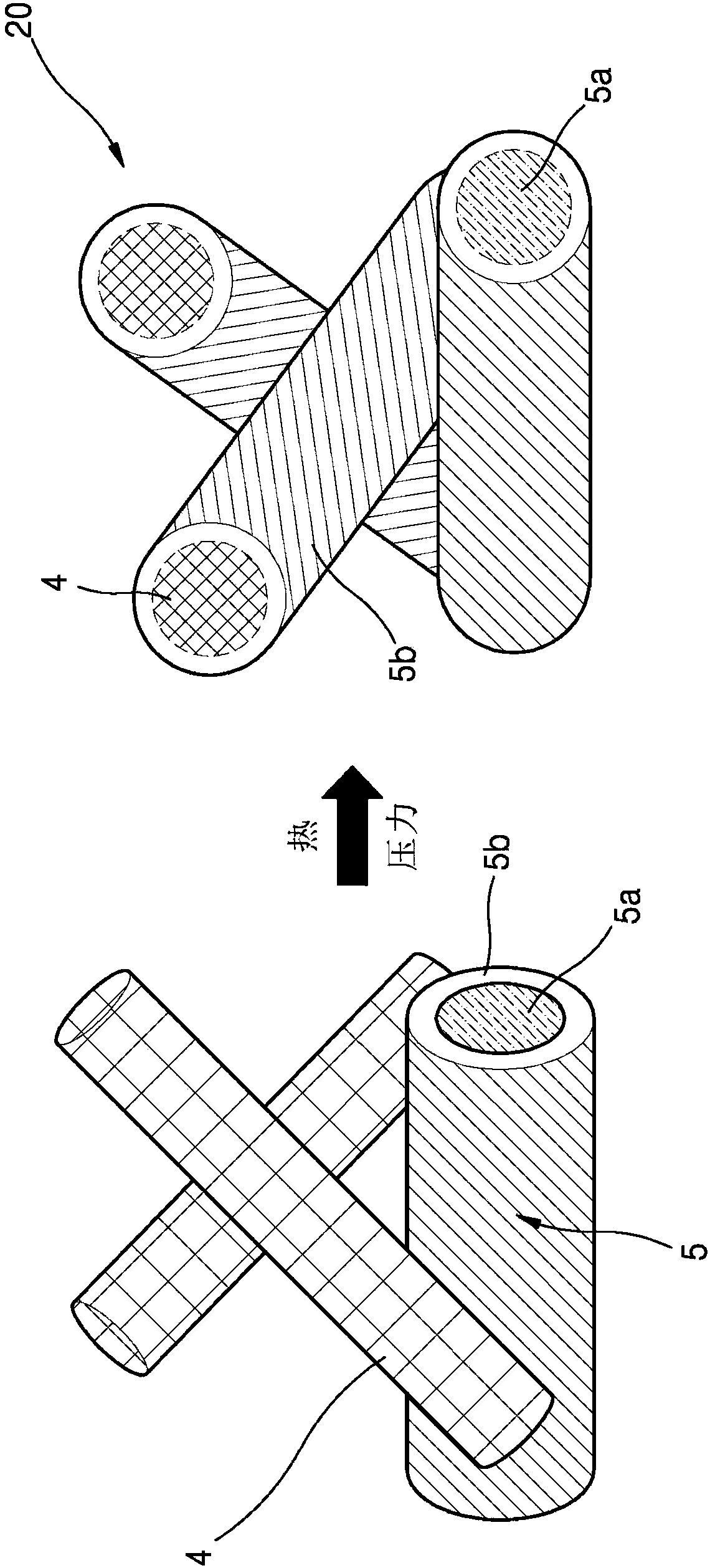

Embodiment 2

[0145] In order to improve the binding force between the polyester resin, the glass fiber with special silane coating treatment on the surface was used instead of the glass fiber used in Example 1. After the composite material sheet is produced in the same way, then, the composite material preformed plate is formed in the same method as in Example 1, and then the above-mentioned composite material is preheated in an IR oven at a temperature of 200° C. for 2 minutes. The material preformed sheet expands and is transferred to the press process at room temperature, and pressure is applied to complete the vehicle underbody cover with an average thickness of 2.0 mm.

Embodiment 3

[0147] With 10 parts by weight of the glass fibers used in Example 2 with a special silane-coated surface and 90 parts by weight of binary polymer fibers, except for this point, in the same manner as in Example 2 Method After the composite material sheet is manufactured, the composite material preformed plate is formed in the same method as in Example 2, and then the above composite material is preheated again in an IR oven at a temperature of 200° C. for 2 minutes. The molded sheet expands and is transferred to a press process at room temperature, and pressure is applied to complete the vehicle undercover with an average thickness of 2.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com