Preparation method of acid-resistant salt-resistant yeast extract

A yeast extract and salt-tolerant technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, vinegar preparation, etc., can solve the problem of high cost, achieve the effect of reducing production cost and enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

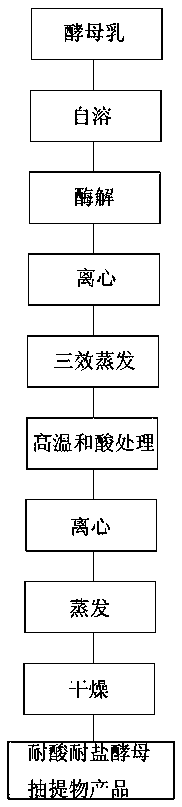

Method used

Image

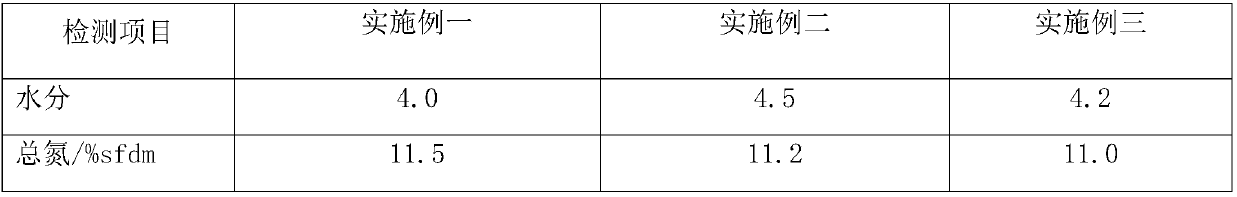

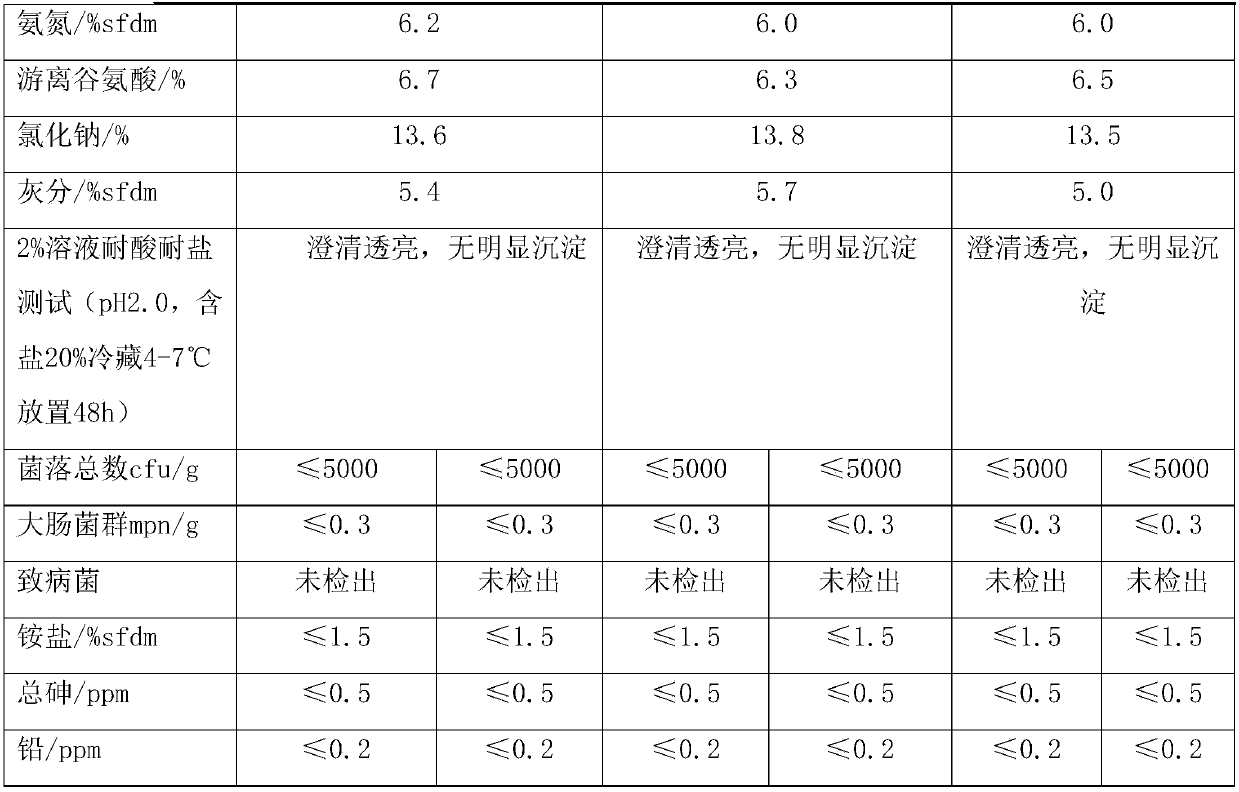

Examples

Embodiment 1

[0032] A. Preparation of yeast slurry: use high-protein Saccharomyces cerevisiae strains to cultivate high-protein yeast milk to obtain yeast slurry with a protein content of 53%, a pH of 5.5, and a solid content of 15%;

[0033] B Autolysis: Add the obtained yeast milk into an autolysis tank and heat rapidly at 55°C for 5 hours, and control the pH to 5.5-6.0;

[0034] C enzymatic hydrolysis: after the end of autolysis, no need to adjust the pH, the temperature is 55 ℃, add 0.3% enzyme for breaking the wall, and enzymatically hydrolyze for 10 hours; After 6 hours of action with special enzymes for food, add flavor protease 0.05%, control pH 5.3-5.8, and enzymatically hydrolyze for 6 hours;

[0035] D Separation of the extract: remove the yeast cell fragments and extract the yeast leaching supernatant. Cell fragments are used as raw materials for biological feed or health products to obtain yeast extract;

[0036] E Three-effect evaporation: Evaporate and concentrate the abov...

Embodiment 2

[0042] A preparation of yeast slurry: use high-protein Saccharomyces cerevisiae strains to cultivate high-protein yeast milk to obtain yeast slurry with a protein content of 55%, a pH of 5.0, and a solid content of 15%;

[0043] B Autolysis: Add the obtained yeast milk into an autolysis tank and heat rapidly at 45°C for 8 hours to control the pH to 5.5-6.0;

[0044] C enzymatic hydrolysis: after the end of autolysis, no need to adjust the pH, the temperature is 55 ℃, add 0.2% enzyme for breaking the wall, and enzymatically hydrolyze for 12 hours; After 8 hours of action with special enzymes for food, add flavor protease 0.08%, control pH 5.3-5.8, and enzymatically hydrolyze for 6 hours;

[0045] D Separation of the extract: remove the yeast cell fragments and extract the yeast leach clear liquid. Cell fragments are used as raw materials for biological feed or health products to obtain yeast extract;

[0046] E three-effect evaporation: the above clear liquid is evaporated an...

Embodiment 3

[0052] A preparation of yeast slurry: high-protein yeast milk is cultivated by high-protein Saccharomyces cerevisiae strains, and yeast slurry will be obtained, with a protein content of 52%, a pH of 5.3, and a solid content of 15%;

[0053] B Autolysis: Add the obtained yeast milk into an autolysis tank and heat rapidly at 50°C for 8 hours, and control the pH to 5.5-6.0;

[0054] C enzymatic hydrolysis: after autolysis, no need to adjust pH, temperature 55 ℃, add 0.1% enzyme for breaking the wall, enzymatic hydrolysis for 12 hours; add 0.2% special enzyme of yeast extract after 4 hours of action of enzyme for breaking the wall, and extract in yeast After 8 hours of action with special enzymes for food, add flavor protease 0.1%, control pH 5.3-5.8, and enzymatically hydrolyze for 10 hours;

[0055] D Separation of extract: remove yeast cell fragments, extract yeast leaching liquid; cell fragments are used as raw materials for biological feed or health products to obtain yeast ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com