Bristle boiling, baking system and bristle processing technology

A bristle and bristle technology, which is applied in the roasting system, bristle processing technology, and bristle cooking field, can solve the problems that the gas stove cannot be heated by the stove, the stove design is not reasonable, and the amount of one-time baking is large, so that the energy consumption is small, Reduce the frequency of manual mixing and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 Boiling mane pot stove

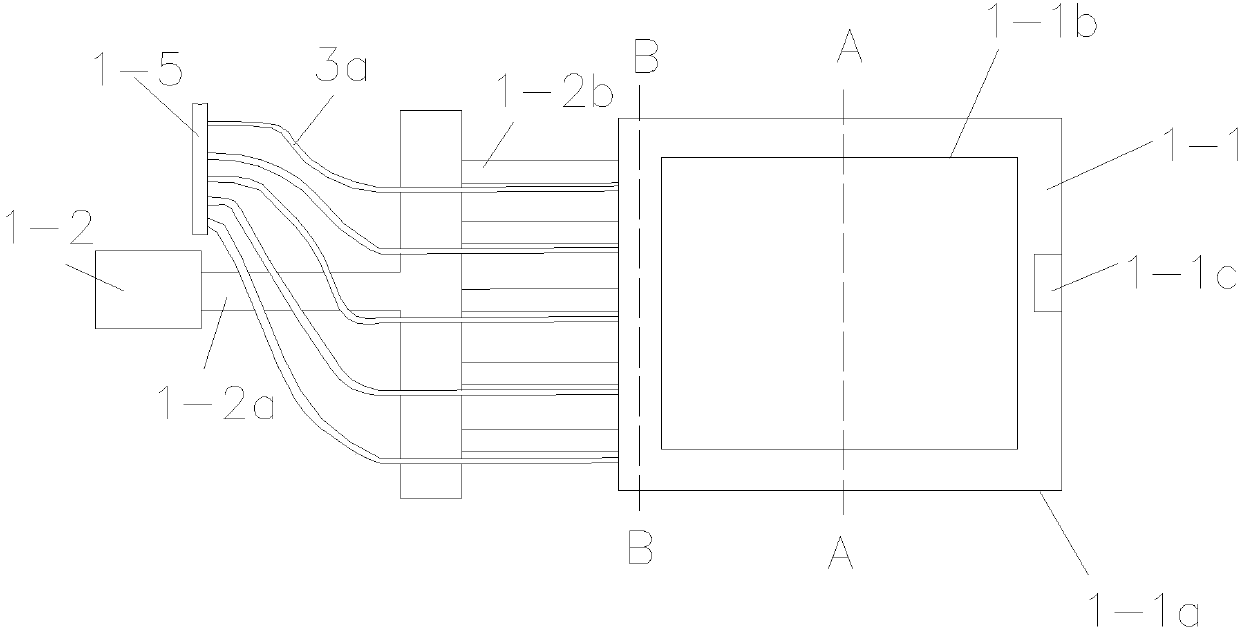

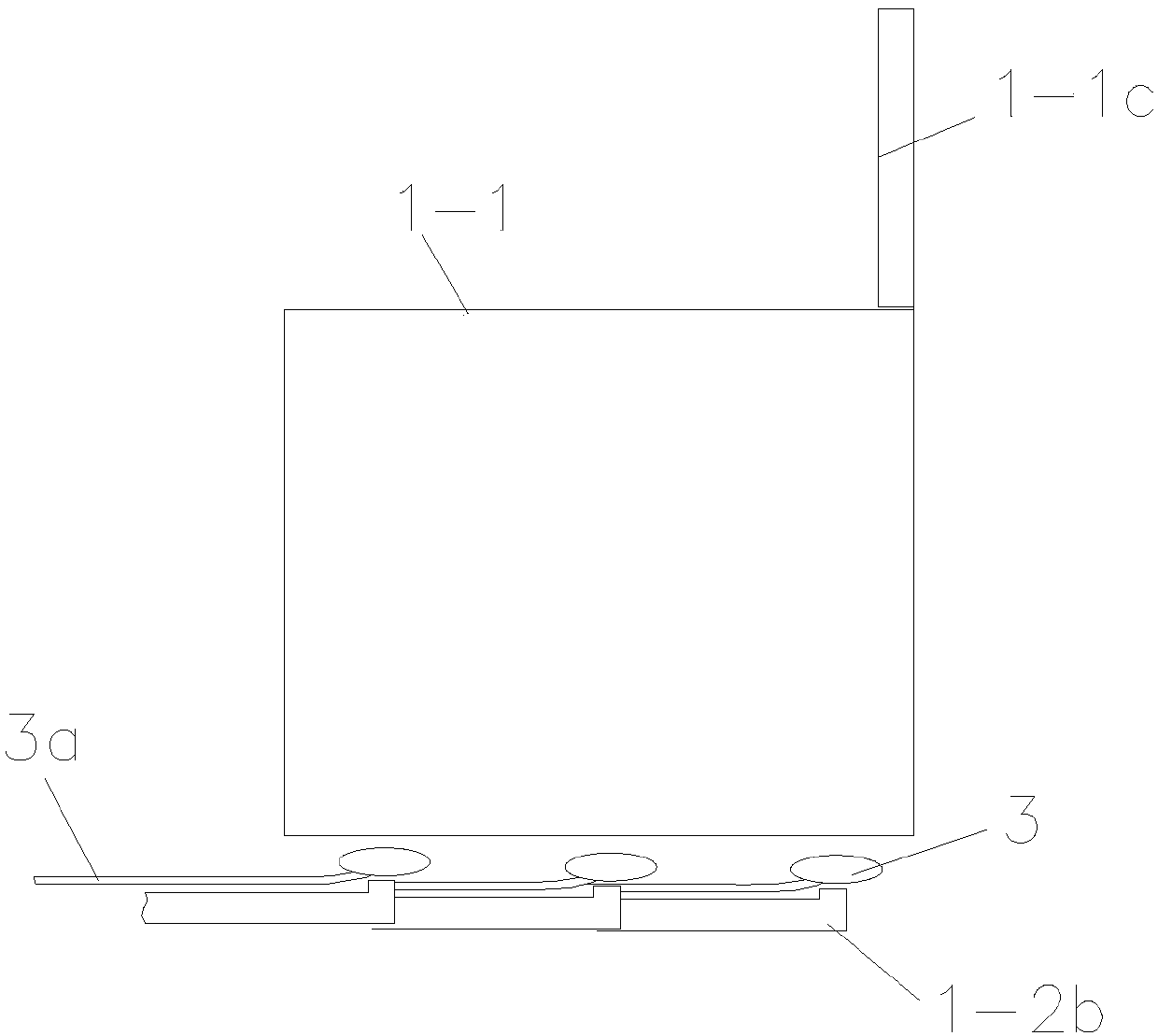

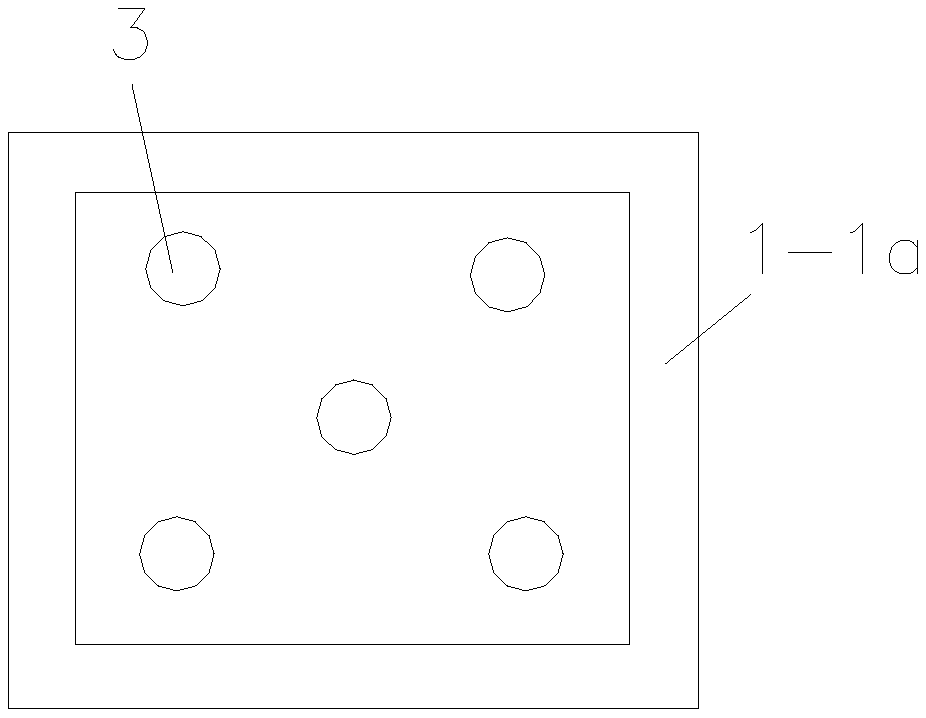

[0036] Such as Figure 1-5 A kind of bristle cooking stove shown mainly is made up of pot body 1-1, air blower 1-2, 5 gas stoves 3. The pot body 1-1 is a double-layer rectangular pool. The four walls of the outer layer of the pool are brick walls 1-1a built on the ground, and the inner layer is a heat-conducting and waterproof layer 1-1b made of aluminum plates. A gap is left between them to form a closed combustion chamber 1-4. The top of the heat-conducting waterproof layer 1-1b is turned outward to form a closed plate 1-1f between the top of the inner layer and the outer layer. The distance between the heat-conducting waterproof layer 1-1b and the brick wall 1-1a is 8-12 cm, so that the flame heat of the gas furnace can reach the gap between the inner and outer layers of the pot, and the pot body can be heated from top to bottom , making the pot body heated more evenly and faster, improving the cooking efficiency of the mane, red...

Embodiment 2

[0040] Embodiment 2 Mane drying chamber

[0041] Such as Figure 6-7 Shown a kind of mane baking room, mainly by the room 2-1 that fireproof material surrounds, two fireproof racks 2-2, 3 gas stoves 3 are formed. Room 1 is equipped with a fire door 2-1a, and the roof is provided with at least one exhaust port 2-1b. The exhaust port 2-1b is connected with an exhaust pipe, and the exhaust pipe extends outside the room to dissipate the The hot air is directed out of the room to speed up drying.

[0042] In the middle of the floor of room 1, there is a strip-shaped pit 2-4 facing the fire door 2-1a. The pit 2-4 extends out of the fire door 2-1a. Three gas furnaces 3 are evenly placed in the pit 2-4. Among them, the gas furnace 3 is connected to the gas main pipe outside the room 2-1 through the gas branch pipe 3a, which is convenient to use, and multiple gas furnaces can be used to heat together at the same time, with fast baking and high work efficiency.

[0043] The ground on...

Embodiment 3

[0046] Embodiment 3 bristle processing

[0047] Bristle has the characteristics of uniform roots, moderate hardness, high oiliness, good toughness, strong elasticity, luster and firmness, moisture resistance, heat resistance, acid resistance, abrasion resistance, etc., and has natural fork tips, good adsorption performance, non-toxic, etc. Features, so it is suitable for making brushes for various purposes. In the bristle processing process, the fat in the bristles needs to be removed by boiling. Boiling and roasting can make the bristles straight and meet the requirements for making brushes.

[0048] The bristle is processed, and the processing technology is:

[0049] (1) Dehairing: use a dehairing machine to beat it twice in a row, beat the raw material wool into rough hair, and remove the broken pigskin, broken hoof corners and soil quality.

[0050] (2) Water washing: Put the messy hair into the bristle washing machine, add 30% washing powder for every hundred catties of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com