Special cleaning machine for PE films

A washing machine and cleaning mechanism technology, applied in the direction of liquid cleaning method, recycling technology, cleaning method and utensils, etc., can solve the problems of dirty cleaning of the sink, many labors, and large water consumption, so as to improve the purity , Reduce energy consumption, reduce the effect of water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the following is only exemplary and does not limit the protection scope of the present invention.

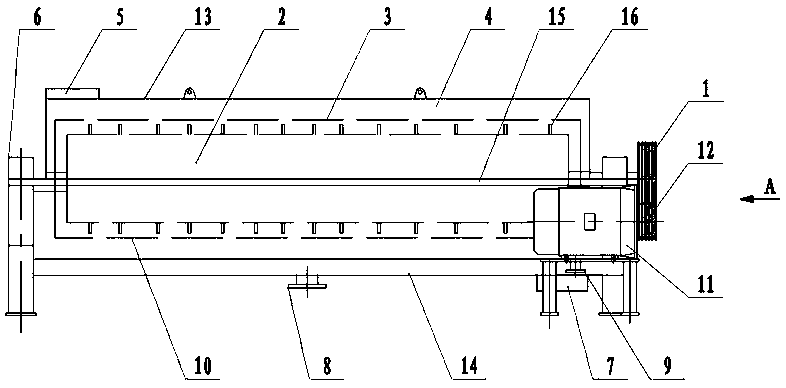

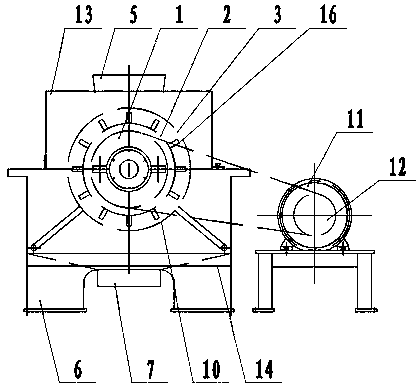

[0018] Such as Figure 1-2 As shown, the special washing machine for PE film of the present invention comprises a housing 4 with a bracket 6 installed at the bottom, and a cleaning mechanism is arranged inside the housing 4, and the cleaning mechanism includes a rotating shaft 15, a rotor 12, several feeding teeth 16, from The moving wheel 1 and the power device, wherein, the rotating shaft 15 is horizontally rotatably installed inside the outer cover 4, the rotor 12 is fixed on the rotating shaft 15 and can rotate synchronously with the rotating shaft 15, and one end of the rotating shaft 15 extends out of the outer cover 4 and It is fixedly connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com