Method for producing cryolite through fluosilicic acid waste liquid

A technology for fluorosilicic acid and cryolite, which is applied in the field of producing cryolite by using fluorosilicic acid waste liquid, can solve the problems of cumbersome preparation process of cryolite, low conversion rate, increased production cost, etc., and achieves short reaction process time and promotes reaction. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

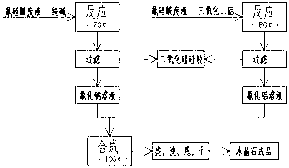

[0022] Such as figure 1 Shown a kind of method that utilizes fluorosilicic acid waste liquid to produce cryolite, comprises the following steps:

[0023] Step 1, the preparation of sodium fluoride solution:

[0024] 1) The fluosilicic acid waste liquid after removing impurities is made into a fluosilicic acid solution with a concentration of 12% and poured into a steel-lined plastic reactor, and then an excess of 10% soda ash is added to the steel-lined plastic reactor (soda ash purity is 98%) to form a feed liquid, stir the feed liquid and heat it to 70°C until the pH value of the feed liquid is 9; the chemical reaction formula is: H2SiF6+3Na2CO3→6NaF+SiO2+3CO2+H2O;

[0025] 2) Filtration: filter the heated feed liquid, filter out silica gel, and the filtrate is sodium fluoride solution, and then prepare the sodium fluoride solution into a sodium fluoride solution with a sodium fluoride concentration of 20%;

[0026] Step 2, the preparation of aluminum fluoride solution:

...

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is that the purity of soda ash is 96%, and the purity of aluminum oxide is 95%; in step one, the feed liquid is heated to a feed liquid pH value of 8.5; in step three, the fluorination The excess value of aluminum solution added is 9%, and the heating temperature is 95°C.

Embodiment 3

[0035] The difference between embodiment 3 and embodiment 1 is that the purity of soda ash is 97%, and the purity of aluminum oxide is 98%; in step one, the feed liquid is heated until the pH value of the feed liquid is 8; in step three, the fluorination The excess value of aluminum solution added is 11%, and the heating temperature is 98°C.

[0036] By adopting the invention to prepare cryolite, the quality and conversion rate of cryolite can be effectively improved, and at the same time, efficient utilization of fluosilicic acid waste liquid can be realized, waste of fluosilicic acid in fluosilicic acid waste liquid can be avoided, and while protecting the environment, Created more value for the development of the enterprise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com