Extraction method of radix tetrastigme hemsleyani polysaccharose

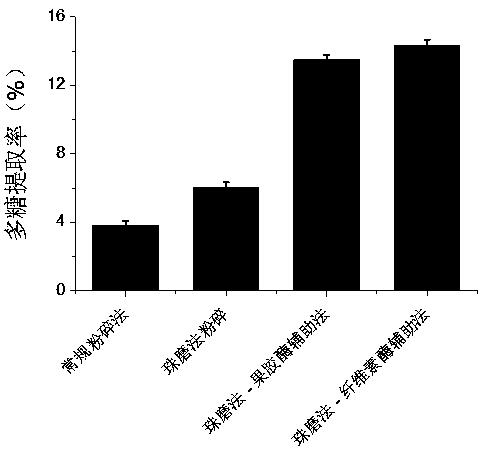

An extraction method, the technology of Cloverleaf, is applied in the extraction of Cloverleaf polysaccharides, using the bead milling method combined with cellulase to assist in the extraction of polysaccharides, which can solve the problems of low extraction rate and slow extraction speed, and achieve simple operation, The effect of reducing time cost and shortening the extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for extracting clover polysaccharides, comprising the steps of:

[0029] Pretreatment: remove dust and other impurities on the leaves of Ivy clover in Fujian;

[0030] S1. Dry the leaves of Ivy clover, pulverize them with an ordinary pulverizer, and sieve them; the pulverization time is 12 hours; after the pulverization, pass through an 80-mesh sieve;

[0031] S2. Treat 5 parts of Clover powder and 30 parts of sterile water at 60°C for 6 hours; the parts are parts by weight;

[0032] S3. Suction filtration; concentrate for 90 minutes at a vacuum of 95kpa and a concentration temperature of 70°C to obtain a concentrated solution; add absolute ethanol 4 times the volume of the concentrated solution to the concentrated solution, and ethanol precipitation for 20 hours; finally dry at -65 ℃, the degree of vacuum is 1pa, and the drying time is 12h to obtain Clover polysaccharide.

Embodiment 2

[0034] A method for extracting clover polysaccharides, comprising the steps of:

[0035] Pretreatment: remove dust and other impurities on the leaves of Ivy clover in Fujian;

[0036] S1. Dry the leaves of Ivy clover, and pulverize them into nano-scale powder through a nano-impact mill, and the pulverization time is 12 hours;

[0037] S2. Treat 5 parts of Clover powder and 30 parts of sterile water at 60°C for 6 hours; the parts are parts by weight;

[0038] S3. Suction filtration; concentrate for 90 minutes at a vacuum of 95kpa and a concentration temperature of 70°C to obtain a concentrated solution; add absolute ethanol 4 times the volume of the concentrated solution to the concentrated solution, and ethanol precipitation for 20 hours; finally dry at -65 ℃, the degree of vacuum is 1pa, and the drying time is 12h to obtain Clover polysaccharide.

Embodiment 3

[0040] A method for extracting clover polysaccharides, comprising the steps of:

[0041] Pretreatment: remove dust and other impurities on the leaves of Ivy clover in Fujian;

[0042] S1. Dry the leaves of Ivy clover, and pulverize them into nano-scale powder through a nano-impact mill, and the pulverization time is 12 hours;

[0043] S2. 5 parts of Clover powder, 30 parts of sterile water, and 0.3 parts of cellulase were enzymatically treated at 55°C and pH 4.5 for 3.5 hours; the parts are all parts by weight;

[0044] S3. Inactivate the enzyme at 100°C for 10 minutes; then extract at 60°C for 7 hours; filter with suction; concentrate for 90 minutes at a vacuum of 95kpa and a concentration temperature of 70°C to obtain a concentrate; add absolute ethanol 4 times the volume of the concentrate to the concentrate , alcohol precipitation for 20 hours; finally, the trilobite polysaccharide was obtained at a drying temperature of -65°C, a vacuum of 1 Pa, and a drying time of 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com