A kind of anti-corrosion and anti-friction coating containing carbon fiber and preparation method thereof

A technology of carbon fiber powder and coating, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of unfavorable large-scale film formation, limited film formation substrate, poisonous and harmful gas, etc., and achieve superior performance , high production efficiency, good effects of wear reduction and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

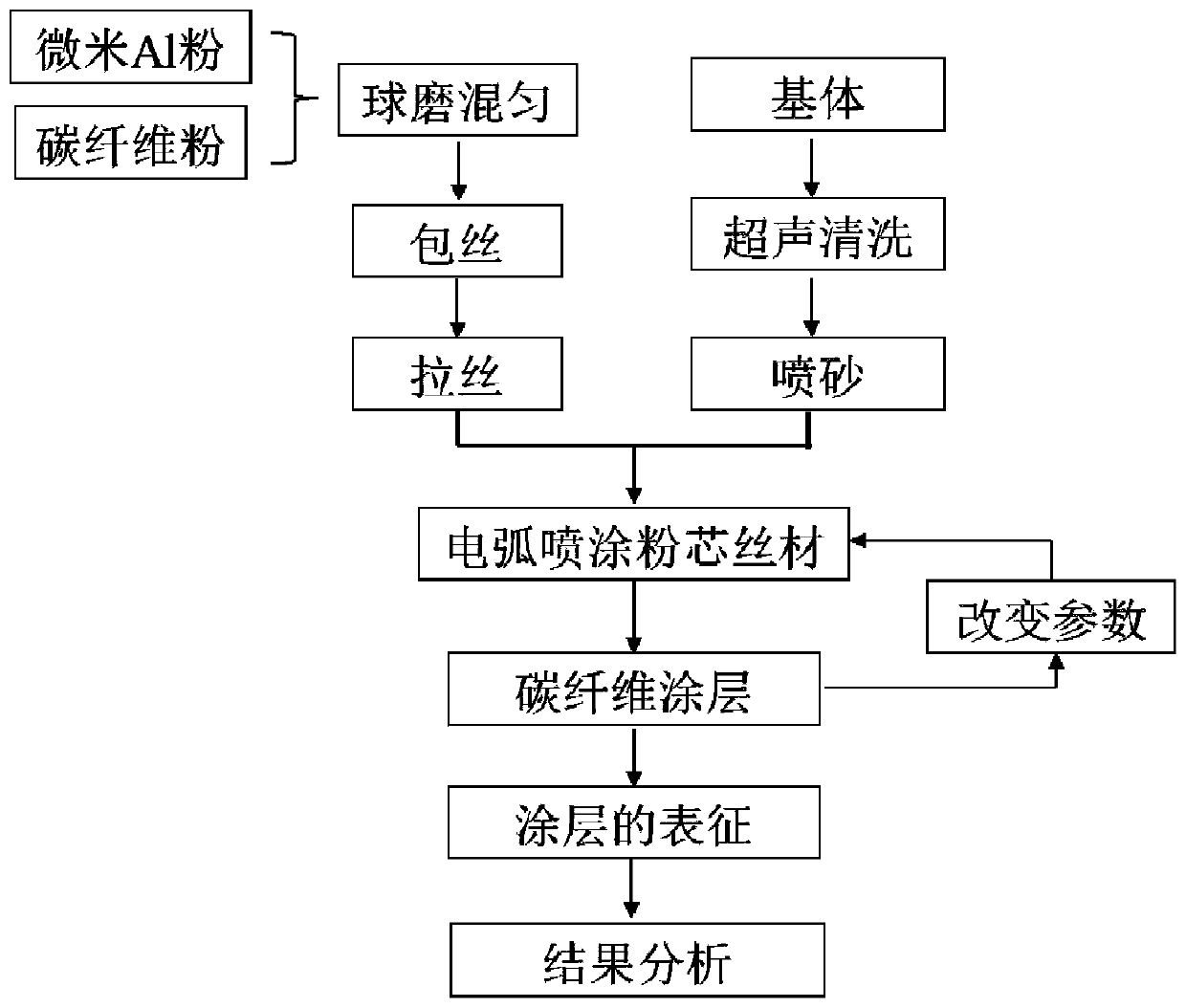

[0036] (1) Preparation of powder core wire:

[0037] Add carbon fiber powder with a particle length of 40-120 μm and a particle diameter of 6 μm and aluminum powder with a particle size of 40-70 μm, wherein the mass ratio of carbon fiber powder to aluminum powder is 3:2, and add them to a ball mill tank. Fully mix under ball conditions, run the ball mill for 10 minutes, so that carbon fiber and aluminum powder are evenly mixed to obtain the powder core material; the corrosion-resistant metal strip is made of aluminum strip, with a width of 10mm and a thickness of 0.3mm, and then wrap the powder core material with a wrapping machine In an aluminum strip, a powder core wire material with a diameter of 2 mm and a filling rate of 25% is obtained through drawing and diameter reduction.

[0038] (2) Coating preparation:

[0039] Using the supersonic arc spraying process, the powder core wire material obtained in step (1) is used as a raw material to prepare a coating on a carbon st...

Embodiment 2

[0045] (1) Preparation of powder core wire:

[0046]Carbon fiber powder with a particle length of 40-120 μm and a particle diameter of 6 μm and aluminum powder with a particle size of 40-70 μm, in which the mass ratio of carbon fiber to aluminum powder is 2:1, are added to the ball mill tank, and the grinding process is carried out without additional grinding. Mix well under the ball condition, run the ball mill for 5 minutes to make the carbon fiber powder and aluminum powder evenly mix to obtain the powder core material; choose the aluminum strip as the corrosion-resistant metal strip, with a width of 10mm and a thickness of 0.3mm, and then wrap the mixed powder with a wire wrapping machine. In the aluminum strip, a powder core wire with a diameter of 2 mm and a filling rate of 20% was obtained by drawing and reducing the diameter.

[0047] (2) Coating preparation:

[0048] Using the supersonic arc spraying process, the powder core wire obtained in step (1) is used as the r...

Embodiment 3

[0054] (1) Preparation of powder core wire:

[0055] Carbon fiber powder with a particle length of 40-120 μm and a particle diameter of 6 μm and nickel powder with a particle size of 100-150 μm, wherein the mass ratio of carbon fiber powder to nickel powder is 3:2, are added to the ball mill tank, and the ratio of ball to material is 3:2. For 10%, the ball mill runs for 10 minutes, and the carbon fiber and nickel powder are uniformly mixed to obtain a powder core material; the corrosion-resistant metal strip is a nickel strip with a width of 12mm and a thickness of 0.3mm, and then the mixed powder is wrapped in the nickel strip by a wire wrapping machine. , a powder core wire with a diameter of 2 mm and a filling rate of 25% was obtained by drawing and reducing the diameter.

[0056] (2) Coating preparation:

[0057] Using the supersonic arc spraying process, the powder core wire obtained in step (1) is used as the raw material to prepare a coating on the titanium alloy sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com