Method for preparing metallographic specimen of spring-like parts

A technology for metallographic samples and parts, applied in the field of testing and testing, can solve problems such as backwater, sample contamination, and the operator's inability to inspect the microstructure normally, and achieve the effect of high surface quality and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

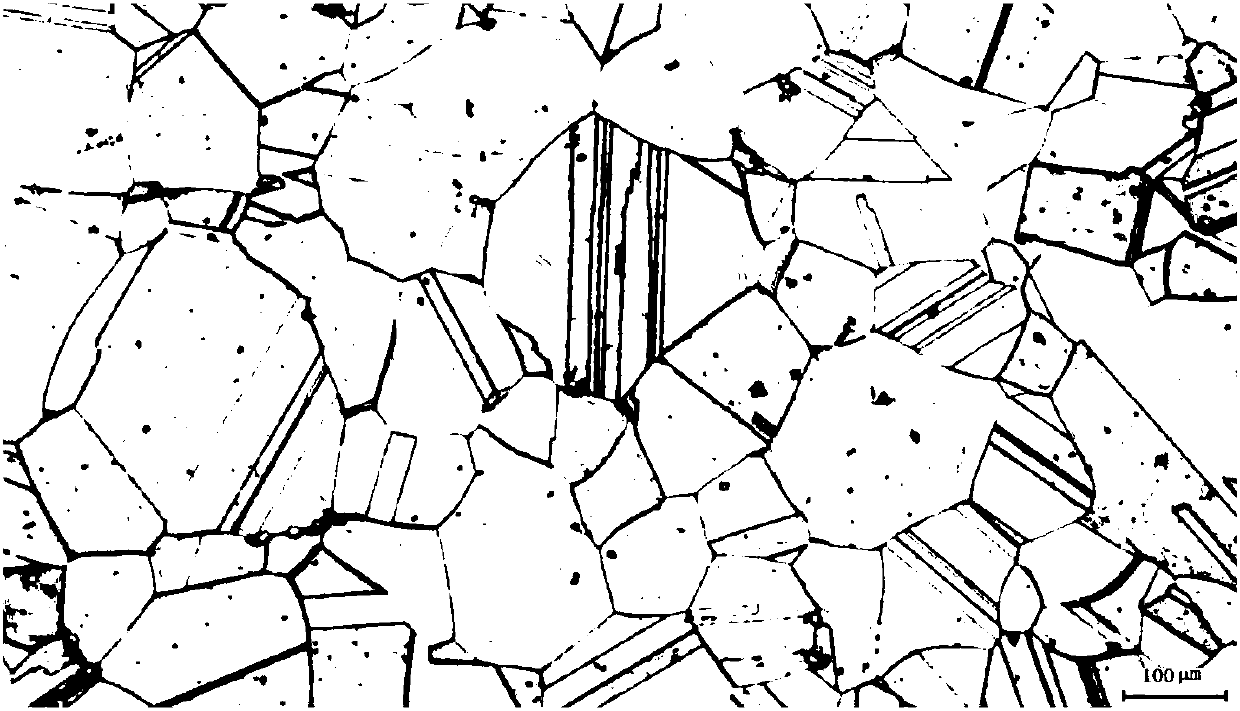

Image

Examples

Embodiment Construction

[0020] Below the present invention is described in further detail a kind of preparation method of metallographic sample of spring class parts, and its concrete steps are as follows:

[0021] (1) Cutting: If the maximum diameter of the part is > 30mm, wire cutting must be used for sampling, and the sampling position is the position to be inspected of the part.

[0022] (2) Clean the sample after cutting with alcohol and dry it with hot air.

[0023] (3) Configure the cold mounting powder Versocit-2Power and the corresponding cold mounting liquid Versocit-2liquid according to a certain ratio (the configuration ratio is 3.5:1, mass ratio) to make it fluid. After the solution is prepared, the sample mounting of the spring parts is carried out. When mounting the sample, the surface to be tested is placed below.

[0024] (4) After the cold-mounted sample is completely solidified, take out the sample and mark the sample accordingly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com