Magnetic suspension electrode dielectric barrier diffuse discharge plasma generation device

A discharge plasma and floating electrode technology, applied in the directions of plasma and electrical components, can solve the problems of limiting the application of atmospheric pressure non-equilibrium discharge plasma, easily burning the material to be processed, uneven processing, etc., and improving the safety of transient operation. performance, avoid power loss, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

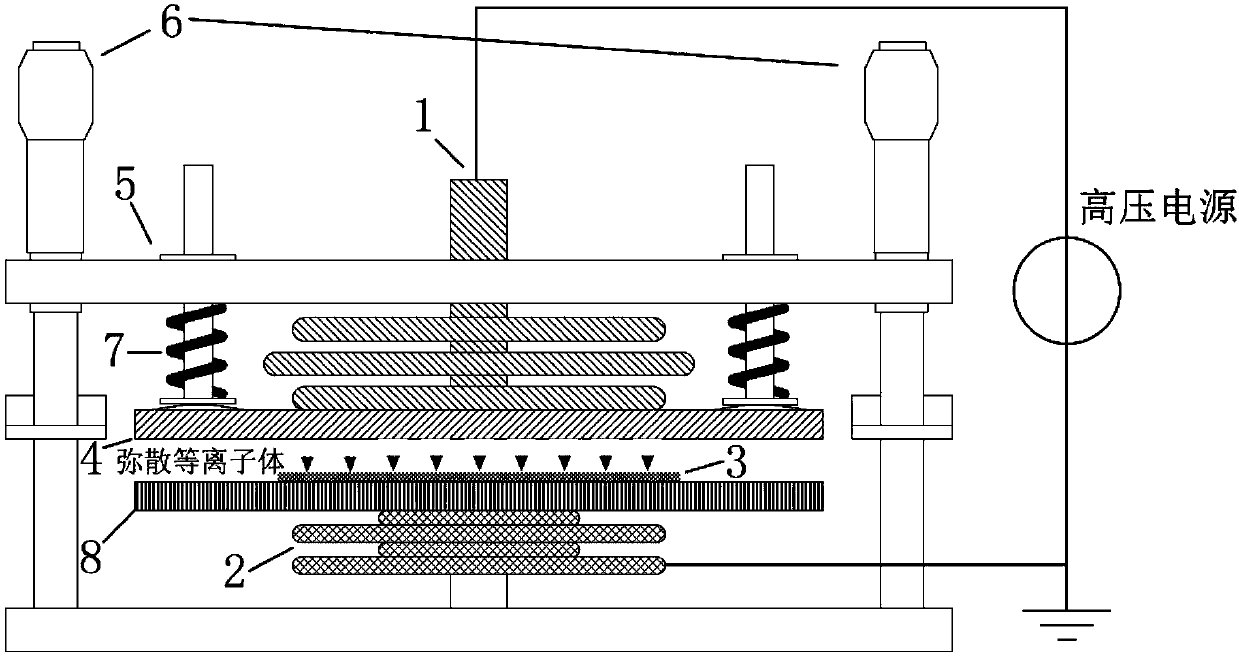

[0036] The overall size of the device of the present invention is about 200×150×50mm, including a polytetrafluoroethylene bracket, the high-voltage electrode is a replaceable electrode with a diameter of 20-50mm, and the magnetic ground electrode is a replaceable laminated permanent magnet with a diameter of 10-30mm, for Generate a magnetic field and adsorb iron powder on the surface of microporous ceramics. When in use, connect the high-voltage electrode to the sinusoidal AC high-voltage power supply, and the lower magnetic ground electrode is grounded. The working voltage waveform is sine wave, the frequency is 10-100kHz, and the working gap width is 5-20mm. Depending on the working gap width, the voltage amplitude is 5.0-16.0 kV adjustable.

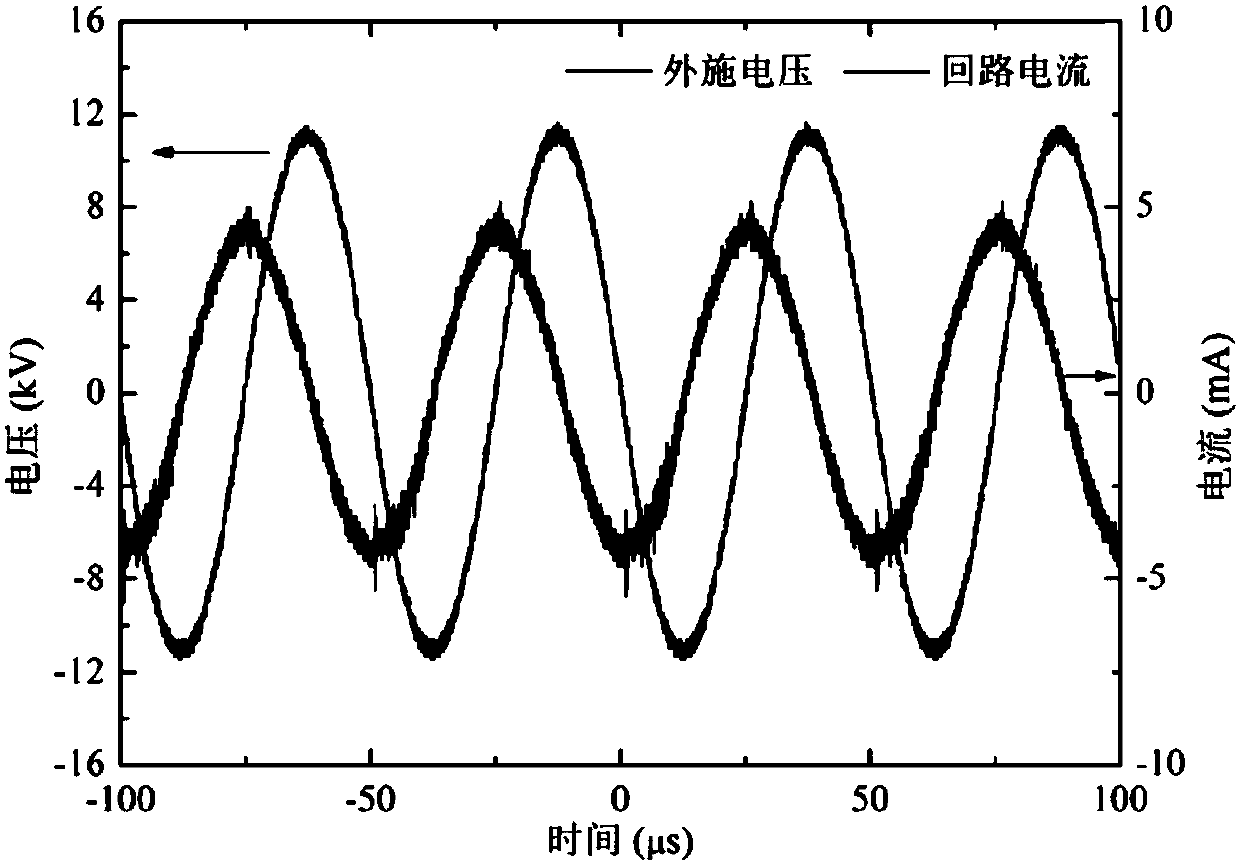

[0037] see figure 2 and image 3 , it can be seen that the device works in a stable diffuse discharge state, with multiple inverted triangle diffuse discharges. This working state corresponds to a gas gap of 6mm, a voltage frequency...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com